A Grandpack Counting Machine Begins Its Journey to Greece

Homogenize the paste using a Emulsifier | Grandpack

The Secrets Behind the High-Performance Soft Capsule Machine

The health and wellness industry is exploding. From Omega-3 fish oils to Vitamin E supplements, consumers love the convenience and effectiveness of softgels. But for manufacturers, the challenge is clear: How do you produce these delicate capsules efficiently, accurately, and at scale?

The answer lies in mastering the soft capsule machine.

Whether you are a pharmaceutical giant or a growing nutraceutical company, understanding the "heart" of your production line is the secret to success. At Grand Machinery, we believe in empowering our clients with knowledge. Today, we are diving deep into the manufacturing of soft gelatin capsule products, the science behind the rolling die principle, and how to seamlessly integrate this into a high-speed Health product bottling line.

The Rise of the Softgel

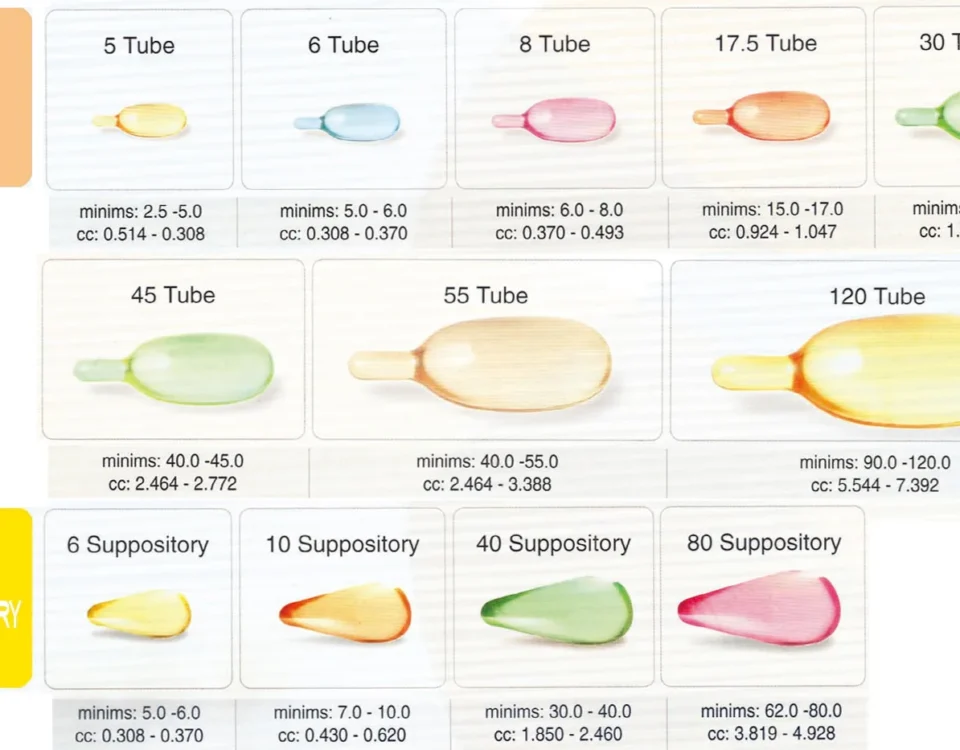

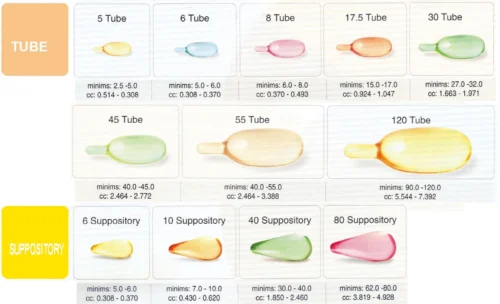

Why are softgels so popular? Unlike hard tablets, a soft capsule (or softgel) is a single-unit solid dosage. It consists of a gelatin-based shell surrounding a liquid or semi-solid fill.

According to industry research, soft capsules are ideal for oil-based drugs and low-melting-point drugs. They offer high bioavailability, meaning the body absorbs them quickly. For products like fish oil, they mask bad tastes and odors effectively. To meet this demand, you need a robust soft gelatin capsules machine.

The Anatomy of a Grand Soft Capsule Machine

A complete soft gel capsule making machine set is not just one device. It is a system. It typically includes the main pressing machine, a conveyor, a dryer, an electric control cabinet, and a vacuum mixing barrel for gelatin.

The Core: The Rolling Die Principle

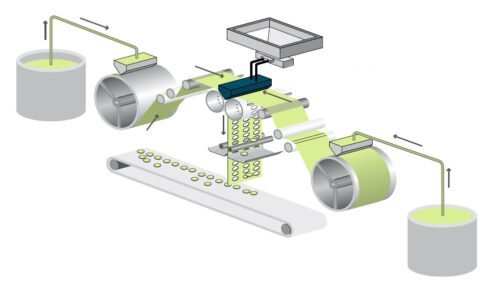

The most efficient method for mass production is the "rolling die" method. Here is the simple breakdown of how our Grand machines operate, based on the specific engineering principles of rolling mode soft capsule pill making machines.

Gelatin Sheet Formation: The machine prepares two ribbons (sheets) of gelatin. The gelatin liquid flows from the gelatin box onto rotating cooling wheels.

Precise Injection: These two ribbons move toward the center. A "wedge injector" sits between two rolling dies. It heats the film and injects the liquid medicine (like fish oil) precisely at the moment the two dies meet.

Sealing and Cutting: The rolling dies rotate. They press the two gelatin sheets together. The heat and pressure seal the capsule instantly. At the same time, the dies cut the capsule shape out of the ribbon.

This continuous process allows for incredible speed and consistency.

Step-by-Step: The Manufacturing of Soft Gelatin Capsules

Let’s walk through the actual production process. If you are operating a Fish oil filling machine, this is your daily reality.

1. Preparation of the Gel Solution

It starts in the gelatin bucket. This is a three-layer stainless steel container. You mix water, gelatin, glycerin, and other materials.

The Pro Tip: Heat the mixture to 80–90°C. Stir for 30–40 minutes.

The Secret: After mixing, you must let it stand at 60°C for more than 10 hours. This ensures a smooth, bubble-free shell.

2. Film Preparation

The gelatin flows into the "gelatin box" on the machine. Here, you adjust the thickness. For most standard softgels, a film thickness of about 0.8mm is perfect. The machine uses cold air to cool and set the gelatin strip.

3. Injection and Encapsulation

This is where the magic happens. A supply pump sends the liquid medicine to the spray body (injector). The pump synchronizes with the rolling dies. It injects the exact dosage into the pocket formed by the gelatin sheets.

4. Drying and Shaping

Fresh softgels are soft and fragile. They fall onto a conveyor belt. This belt transports them to the tumble dryer (rotating cage).

Initial Drying: The capsules roll in the basket for about 4 hours for shaping.

Final Drying: They are then moved to a drying room for approximately 16 hours to harden completely.

Troubleshooting: Practical Tips for Operators

Even the best soft gelatin capsules machine needs a skilled operator. Based on technical research, here are solutions to common problems you might face on the factory line .

Problem: Leaking Capsules (The "Leaky Oil" Issue)

Cause: The medicine inside might contain particles that are too large, blocking the seal.

Solution: Ensure your medicine powder or paste is ground to a fineness of below 100 mesh. If particles are larger than 100 mesh, leaks are common.

Problem: Asymmetric Shapes

Cause: The gelatin film thickness is different on the left and right sides.

Solution: Adjust the gap on the gelatin box to ensure both ribbons are exactly the same thickness (e.g., 0.8mm).

Problem: Bubbles in the Capsule

Cause: There is air in the medicine liquid supply.

Solution: Check the pipeline seals and ensure the liquid is de-aerated before filling.

From Encapsulation to Health Product Bottling

Making the softgel is only half the battle. Now you must package them. This is where Health product bottling lines come into play.

After drying, the softgels are stable. They are moved to the counting and filling stage. At Grand Machinery, we provide integrated solutions for this.

The Role of the Counting Machine

For softgels, accuracy is critical. You cannot simply weigh them because the gelatin shell weight varies slightly. You need an electronic counter. As seen in our factory shipments, we utilize robust machines like the ZC-4A four-channel desktop counting machine.

Protection: These machines are shipped in sturdy wooden boxes reinforced with metal clasps to ensure they arrive safely at your facility.

Setup: We include a detailed User Manual with every machine, sealed in plastic to prevent moisture damage during shipping.

Function: These machines vibrate to separate the softgels and count them optically before dropping them into bottles.

This ensures that every bottle of fish oil or Vitamin D has the exact count promised on the label.

Hard Gelatin and Soft Gelatin Capsule: What’s the Difference?

Clients often ask us about hard gelatin and soft gelatin capsule differences.

Hard Gelatin Capsules: These are two pieces (a body and a cap). They are usually filled with dry powder or pellets. They are sealed mechanically.

Soft Gelatin Capsules: These are a one-piece hermetically sealed shell. They are formed, filled, and sealed in one operation on the soft capsule machine.

Why choose Softgel? If you are manufacturing liquids, suspensions, or oils (like Fish Oil), the softgel is the superior choice. It is tamper-resistant and easier to swallow.

A Partner You Can Trust

Choosing a soft capsule machine is a major investment. You need more than just a vendor; you need a partner who understands the chemistry of gelatin and the mechanics of bottling.

Our Sales Manager, Helen Xiao, puts it best:

"We have specialized in soft capsule machines for 19 years. From soft capsule manufacturing to packaging, we provide a complete set of production equipment and are a partner for many health product companies and pharmaceutical manufacturers."

This experience matters. It means we understand that a fish oil filling machine needs specific temperature controls. We know that the die rolls must be aligned with a tolerance of less than 0.05mm. We know that the drying room humidity must be kept between 20% and 35%.

Conclusion: Elevate Your Production Today

The market for health products is not slowing down. To capture your share, you need efficiency. You need a soft gel capsule making machine that delivers consistent, leak-free, and high-quality capsules every single time.

From the initial gelatin melting to the final packaging in our robust counting machines, Grand Machinery offers the end-to-end solution you have been looking for.

Don't let inefficient equipment hold your business back. Whether you are troubleshooting a leaky seal or setting up a brand-new Health product bottling line, we are here to help.

Ready to upgrade your manufacturing capabilities? Contact Grand Machinery today. Let’s build your success, one capsule at a time.

"We have specialized in soft capsule machines for 19 years. From soft capsule manufacturing to packaging, we provide a complete set of production equipment and are a partner for many health product companies and pharmaceutical manufacturers."

"We have specialized in soft capsule machines for 19 years. From soft capsule manufacturing to packaging, we provide a complete set of production equipment and are a partner for many health product companies and pharmaceutical manufacturers."