What is the gap between generic drugs and original drugs?

Why are Athlete Injuries and Medical Technology Advances Inseparable?

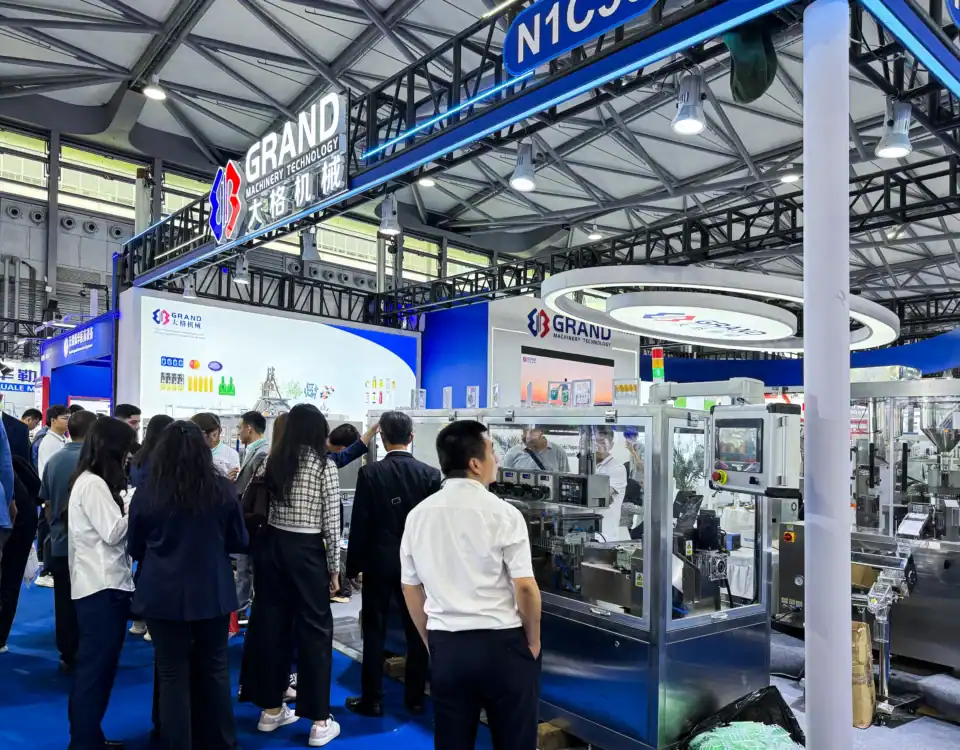

Grand Joins Sino-Pack 2025 Exhibition Site Report-Packaging Line Automation

On March 4, 2025, Sino-Pack 2025 (concurrently held with PACKINNO 2025), one of the annual events in the packaging industry, was grandly opened in Guangzhou.

The exhibition not only gathered intelligent packaging equipment, packaging materials, and packaging technologies from all over the world but also showed the main theme of transformation and upgrading of the future packaging industry in the major forums and booths, in which Grand's staff actively participated and shared the cutting-edge technologies and technologies around the core keyword of “packaging line automation.".

Around the core keyword “packaging line automation," Grand's business staff also actively participated in the exhibition, sharing cutting-edge technologies and innovations and injecting new momentum into the industry.

Background of the exhibition and Grand's participation

With the theme of “Intelligent Packaging and Materials," Sino-Pack 2025 and PACKINNO 2025 attracted famous enterprises, industry experts, and professional visitors from all over the world. Driven by the wave of “Industry 4.0” and “Digital Transformation," packaging automation solutions have gradually become the focus of the industry. Grand, as a leading company focusing on packaging line automation, has been deeply engaged in the research, development, and implementation of automated packaging production lines and is committed to providing customers with efficient, reliable, and sustainable packaging automation solutions.

In this exhibition, Grand's business team brought the latest packaging automation products and application cases, including high-speed packaging robots, intelligent conveyor systems, automatic labeling, and inspection systems. Through real project cases and on-site demonstrations, Grand showed how to use packaging line automation technology to help enterprises reduce costs and increase efficiency, improve product quality, and meet diversified and individualized market demands.

Exhibition Highlight: Grand's “Packaging Line Automation” Tour

High-speed Robots and Intelligent Vision

Under the trend of intelligent production, robots have become indispensable employees in packaging workshops, and Grand's high-speed robot system, through the deep integration of intelligent vision, can quickly identify the position and attitude of products and realize high-speed sorting, palletizing, packaging, and other functions.

The advantages of this system include high speed and stability, 24-hour uninterrupted operation, and with the total solution of packaging line automation, it can effectively improve the efficiency of the production line, reduce labor costs, and lower the error rate.

Flexible and adjustable conveying and sorting system

The flexible conveying and sorting system demonstrated at Grand's booth has become the focus of visitors' attention for different industries and product forms. The system can automatically adjust the conveying track and sorting module according to the product size and packaging requirements, and with the intelligent scheduling of the packaging line automation management platform, it can realize “one-click switching” of different production modes, significantly shorten the time of production line transformation and debugging, and significantly enhance the flexibility of the production line.

Automatic labeling, inspection and data traceability

Labeling and quality inspection is a critical part of the packaging process, and the automatic labeling and inspection system brought by Grand combines high-precision sensors and AI algorithms to monitor the labeling position, size, and printing quality in real time and then trace and analyze them through the packaging line automation data platform. This not only reduces the scrap rate but also helps enterprises realize the supervision and tracking of the whole life cycle of products.

Digital Management Platform and Cloud Connectivity

In order to enable enterprises to fully grasp the packaging production process, Grand highlighted its digital management platform at the exhibition. Through the Internet of Things (IoT) technology and cloud interconnection, Grand can help customers obtain production data in real time and conduct visualization and analysis. Combined with the intelligent scheduling system of packaging line automation, managers can quickly understand the bottlenecks in production and optimize them, realizing the true meaning of “intelligent decision-making” and laying a solid foundation for the long-term development of the enterprise.

Grand's Exhibition Achievements and Industry Impact

The appearance of Grand's business staff at Sino-Pack 2025 attracted a large number of visitors and industry insiders. Many visitors expressed their interest in Grand's automation equipment on the spot and actively learned about the technical details and application cases. For the packaging needs of pharmaceutical, food, daily chemical, and other industries, Grand customized solutions for customers on the show floor.