Granulators in the Pharmaceutical Industry – A Comprehensive Overview

Top 4 Best-Selling NJP Series Capsule Filling Machines

Soft Gel Capsule Making Machine: Types, Working Principles, Application and Tips for Buying

Soft gel capsule making machines have become very popular worldwide, especially as the number of capsule requirements is increasing. That’s why it’s imperative to know what type of machine you should buy. Learning more about the soft gel capsule making machine, its features, how many capsules per hour it can do, all of that info will help immensely. Here’s what you need to know!

Key Components of a Soft Gel Capsule Making Machine

The soft gel capsule making machine is designed to be very effective and comprehensive. It also features multiple parts, each with its own specific requirements and guidelines. Making sure that everything is easy to use does help quite a bit, and it will bring in a more cohesive experience.

Medicine hopper

The medicine pump has a very specific role, and that’s to keep the liquid formulation that you will eventually push into the softgel capsules. The idea here is that you have a small glass window to see the liquid level.

Medicine pump

A medicine pump is found right under the hopper and the role is to send the formulations to the injection edge. The pump is also called a material feeding pump and it will pump material from the hopper and through the tube. Usually, the pump is made out of stainless steel.

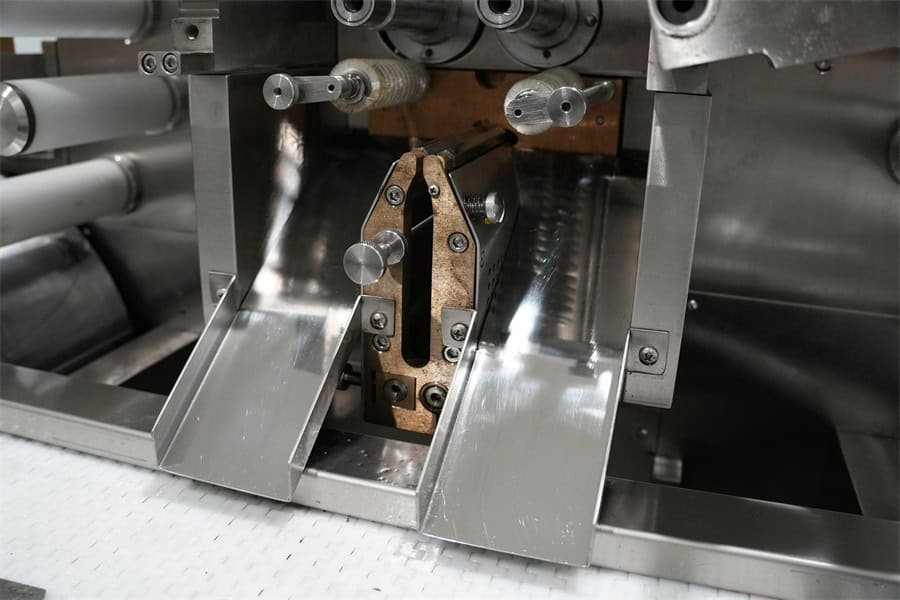

Injection wedge

The wedge or injection wedge is a section shaped in the form of a wedge that will heat up the web and ensure it maintains the right temperature. These days, machines will have sensors for motion and temperature detection, and they can be incredibly powerful.

Medicine tank

These tanks are FDA and cGMP compliant. They are normally built using stainless steel and their focus is to ensure that they maintain the material and prepare it for the encapsulation process of the soft gel capsules. Due to their nature, these tanks have a conical shape.

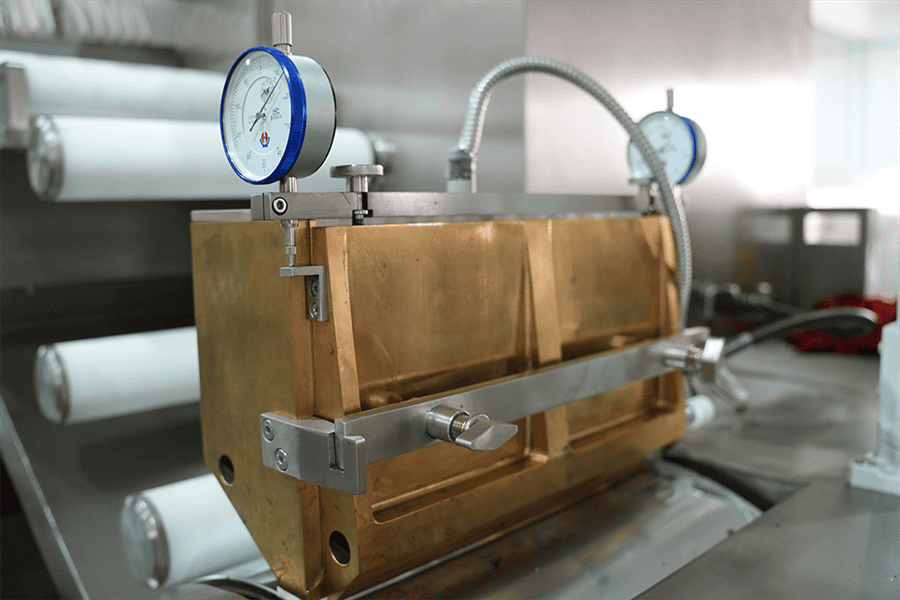

Gelatin Spreader Box

As the name suggests, the unit spreads gelatin, and it will form a thin film. A soft gel manufacturing machine will have 2 spreader boxes, one on each side of the machine. That increases the efficiency of the product, while also making it easy for you to produce a larger number of capsules at once.

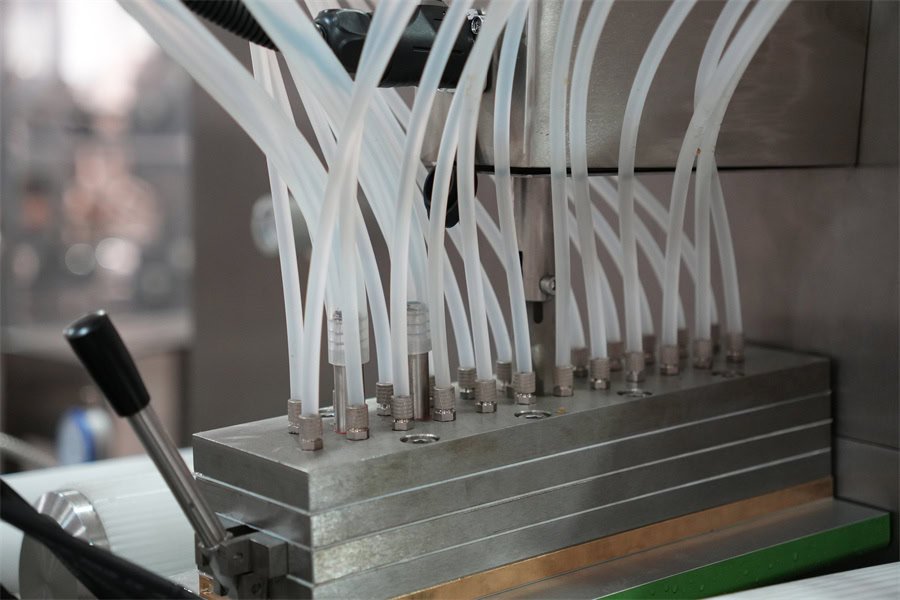

Material feeding pump system

Normally, this is found above your hopper and it has a simple role: it will suck material and then send it to the injection edge. It will have feeder and return tubes, in case the material will need to come back. Since we are working with tubes here, the machine will track the overall pressure and thus it keeps any damage away from the tubes.

Cooling drum

Cooling drums will cool the gelatin web, all while being in constant, rotative motion. There are water or fan-operated cooling drums, each with their own features.

Chilling system

There will be some machines that have a dedicated chilling system. The role of such a chilling system is to keep the gelatin at the right temperature. You get to set and control the temperature at all times.

Gelatin melting and mixing tank

Some of the soft gelatin encapsulation machines will have these tanks integrated, or they need to be acquired separately. The tank will allow you to melt and mix gelatin until it reaches the desired composition. These tanks can have clamps, wall jackets and valves. In order to maintain safety and great product quality, it’s usually made from stainless steel.

Lubrication rollers

A lubrication roller’s main focus is to ensure the gelatin web is tightened. That’s great because it eliminates wrinkles, which could be a problem when it comes to the capsule quality.

Tumble dryer

Some machines will also have a tumble dryer. It will help remove any moisture found on the capsules. Moisture can lessen the effectiveness of these capsules, so you want them to be moisture-free. And that’s where a tumble dryer comes in handy.

Stripper roller

The role of a stripper roller is to get those gelatin capsules from the web and remove, then collect them in a separate space.

Die roll brush

This brush is designed to remove any of the capsules that are stuck on the die rolls. Sometimes, these will get stuck and it will become a problem.

Discharge chute

A discharge chute will take the capsules from the die system and here they move to the conveyor. It’s basically a method of transporting the capsules from one spot to the next.

PLC touchscreen

The soft gel capsule making machine will also, usually have a PLC touchscreen, where you can monitor every stage, pause the process and make any adjustments as necessary.

Working Principle- How Does The Soft Gel Capsule Making Machine Work?

- First, the liquid formulation is added into the medicine hopper, which is on top of the medicine pump. The pump will deliver the metered formulation to the injection wedge.

- When the injection wedge receives the formulation, its role is to inject it into the soft gelatin capsules.

- As the gelatin enters the encapsulator, it will go into the spreader box, where the gelatin will be stored and cast into a drum to create the ribbon. Then the casting drum will solidify the ribbon, since its role is to cool everything down.

- The capsules will go through lubrication rollers, and after getting lubricated, they will go through the die roll brush and mangle roller that will remove softgell problems. The conveyor will push these to the tumble dryer and after drying, the entire process will be finished.

Types of Soft Gel Capsule Making Machines

Using soft gel capsule making machines is an excellent idea if you want to ensure you deliver the best capsules for your customers. Ideally, these machines need to have a very high turnover when it comes to the number of capsules used. But there are also different types of soft gel capsule making machines, as follows:

Manual soft gel capsule making machines

These manual machines are meant from the ground up to require human attention. They have all the elements in place, but you need a human to go through the entire process and handle everything. It limits errors, sure, however it’s time-consuming as well.

Automatic soft gel capsule making machines

With these automated soft gel capsule making machines, every process is fully automated. That means you can easily set it up and forget it. All you have to do is to fill up the material in the beginning and take all the capsules at the end to store them properly.

Small or large scale machines

Aside from the type of utilization, you can also find machines suitable for different users. If you have a smaller business, then a small scale machine is ideal. However, for any medical business that needs to create capsules at a very fast pace, using large scale soft gel capsule making machines is preferred.

Applications of Soft Gel Capsule Making Machines

The clear benefit of soft gel capsule making machines is they are very useful at making pills at a very high speed. These machines can be suitable for a multitude of industries

softgel capsules

Pharmaceutical

The primary use for these machines is in the medical production and pharmaceutical world. Medical products need to be kept in capsules because otherwise any water or air exposure would change their consistency. That will also affect the potential results provided by the medical product. That’s the reason why capsules are one of the most common types of delivery for medical products.

Supplements

A lot of supplements come in the form of capsules, and that’s why these soft gel capsule machines can be extremely useful in the supplement niche. No matter if we are talking about workout supplements, vitamins or natural supplements, many of them are sold in the capsule format because it keeps their benefits and they last for a lot more time. Plus, exposure to the elements can mess up the quality of these supplements.

Health Food

Healthy foods can sometimes come in the form of capsules. That’s why these soft gel capsule making machines have become very popular in the world of health foods. Capsules will dissolve in your stomach, and they are also very easy to ingest. That’s why they have become a staple especially in the case of survival-focused foods or those that are powerful and need to be shared in a very specific dosage.

Tips for buying a soft gel capsule making machine

Purchasing a soft gel capsule making machine is extremely important for many businesses, no matter if you are in the food, supplement or medical sector. But how can you pick the right machine? Here are some criteria and features for you to take into account.

- Ideally, you want to go for a machine that’s fully automated. It will help you save time, while minimizing any issues. You just set the right program and forget it, which can lead to some very good results.

- Think about the noise levels, check the decibel levels for the machine, will it be noisy or not?

- How is the installation process, is the machine easy to assemble or not? Also, if a certain part of it breaks, can you reach the part with ease, or does it require a complete disassembly? All these things will matter quite a bit.

- Power consumption is crucial, especially if you want to buy multiple machines. You want to see if it fits your facility, and if the machine is consuming too much power.

- Another major aspect to consider is how many capsules the machine can produce a day. Depending on the machine, it could be anywhere from 5000 to 30000 or even more capsules per day.

- Does it integrate well with encapsulation machines? Ideally, you want to ensure that you have a streamlined method of using these machines, and it all works as expected.

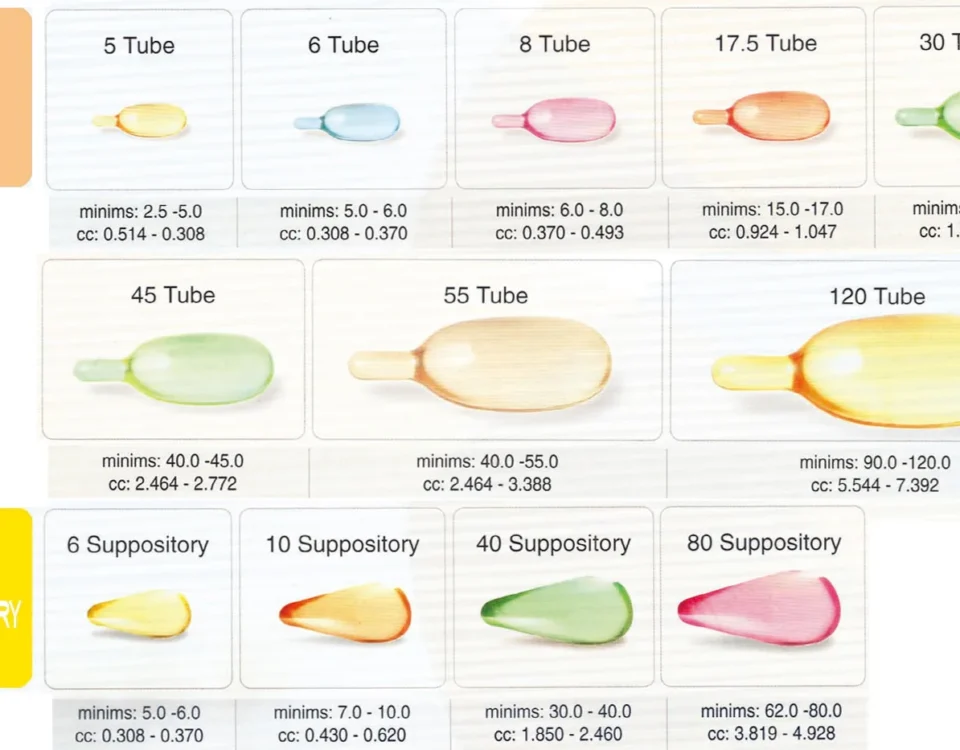

- Check the technical specifications of the machine. You want to see what accessories are included, what capsule dimensions are supported, but also the machine speed and what mold sizes you can use.

- You want to check if it’s possible to change the encapsulation tooling. Ideally, the machine should be able to create different shapes and designs for the capsules, if possible.

- And lastly, you should also check the brand reviews or even reviews for that specific model you are interested in. That will help you narrow down and see whether the model in question is good for you or not!

FAQ

What is the Average Production Capacity of Softgel Manufacturing Equipment?

It depends on the machine, but usually these can make up to 30000 soft gel capsules a day. This is valid for the larger machines. Smaller scale units tend to create around 5000 to 10000 capsules per day.

What should you Consider when Buying Softgel Encapsulation Machine?

These soft gel capsule making machines are meant to provide very high quality results, a clean and safe production environment, among with automation features. You can easily select the desired functions and the machine will provide a very good, outstanding results very fast.

Which Softgel Manufacturing Equipment does Grand offer?

Grand provides large and small scale soft gel capsule making machines that can help you create state of the art, high quality manufacturing equipment. These can also be adapted to special customer requests, as needed.

Conclusion

There’s no denying that soft gel capsule making machines can be ideal for the medical industry, but they can also be used in other niches. With a good soft gel capsule making machine, it becomes a lot easier to ensure you’re making the best possible capsules on the market, while delivering exceptional value. In addition, you will have a consistent way of creating capsules for your company!