How Pharmaceutical Tablet Shape Impacts Integrity?

Grand Ternary vs Circular Swing Screening Machines – Comparison & Guide

Tablet Counter Guide (2025): Pharmacy & Industrial Machines

Choosing the Right Tablet Counter: From Desktop Models to High-Speed Systems

In the pharmaceutical, nutraceutical, and food industries, accuracy isn't just a goal—it's the absolute standard. Whether you're bottling supplements, prescribing medication, or packaging confectionery, every single item counts. Manual counting is not only slow and labor-intensive but also prone to human error, which can lead to significant consequences, including incorrect dosages, regulatory non-compliance, and financial loss. This is where the automatic pill counting machine becomes an indispensable asset.

But with a wide array of tablet counters on the market, how do you choose the right one for your specific needs? The answer lies in understanding the technology, from compact desktop units perfect for labs and pharmacies to industrial-scale systems designed for mass production. This guide will explore the different types of tablet counters, delve into the advanced technology that powers them, and help you identify the perfect solution for your operational scale.

Why Accuracy Matters: The High Stakes of Pill Counting?

Before we examine the hardware, it's crucial to understand why precision is so vital. An inaccurate count can lead to:

Safety and Compliance Risks: In a pharmaceutical setting, an incorrect pill count can result in a patient receiving the wrong dosage, a critical safety issue. This can lead to severe regulatory penalties from bodies like the FDA.

Financial Losses: Consistently overfilling bottles, even by one or two tablets, adds up to significant product giveaway and lost revenue over thousands of units.

Damaged Brand Reputation: Customers who receive underfilled bottles lose trust in a brand's quality control, leading to complaints and a damaged reputation.

An automatic tablet counter machine mitigates these risks by replacing manual guesswork with technological precision.

The Workhorse for Startups and Pharmacies: The Desktop Tablet Counter

For businesses that require accuracy and efficiency but may not have the floor space or output demands for a large industrial machine, the desktop counter is the perfect solution. These machines are ideal for R&D labs, small-scale production runs, and as a tablet counter pharmacy solution.

Grand ZSL-A: A Compact Powerhouse of Precision

A prime example of excellence in this category is the Grand ZSL-A Crawler Type Electronic Number Machine. It is a high-tech counting equipment that integrates optical, mechanical, and electronic motors. Designed according to GMP standards, this machine provides a powerful, compact, and user-friendly solution.

How It Works: The ZSL-A's workflow is both simple and ingenious. Materials are poured into the storage hopper and, through controlled vibration and an electric turntable, they slide down a channel. An optical fiber sensing system and control system then count the items as they are filled into a bottle through the discharge port. Once the preset number is reached, the system instantly diverts the flow, stops the vibration, and waits for the next bottle to be positioned.

Key Features:

Versatility: The ZSL-A is widely applicable for the fast counting and bottling of tablets, hard and soft capsules, pills, and other uniformly shaped items. It can handle capsule sizes from 000# to 5# and tablet diameters from 5mm to 25mm.

High Precision: Utilizing an infrared detection counting method , the machine achieves a counting error of just ±0.3% , reaching an advanced level of accuracy for products in its class.

Advanced Technology: The machine incorporates some of the most advanced technologies, including a vibrating feeding system, an intelligent touch screen PLC controller, and a fiber optic probe counter. The configuration list boasts high-quality components from world-renowned brands like Japan's KEYENCE and OMRON for its sensors and amplifiers.

User-Friendly Operation: It features a touch screen for setting parameters like the number of grains per bottle and the total number of bottles to be filled. The operator also has manual switches and knobs for fine-tuning the vibration power and turntable speed.

Scaling Up: The High-Speed Multi-Channel Automatic Tablet Counter Machine

When production demands grow from thousands of units to millions, a more powerful solution is needed. High-speed, multi-channel pill counting machines are the answer for large-scale pharmaceutical and nutraceutical manufacturers. These machines use multiple lanes to count products simultaneously, dramatically increasing throughput.

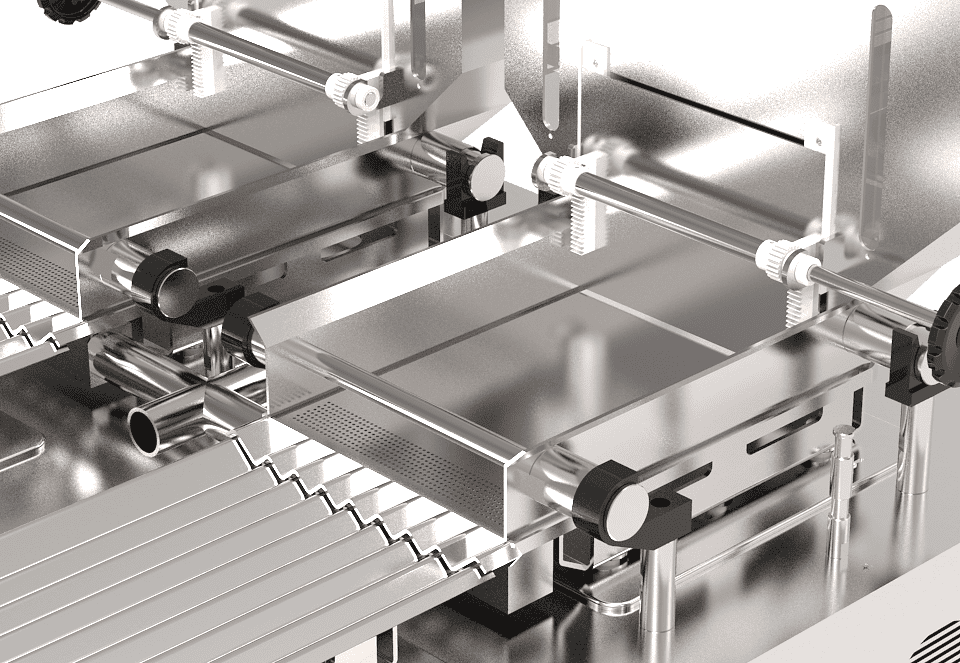

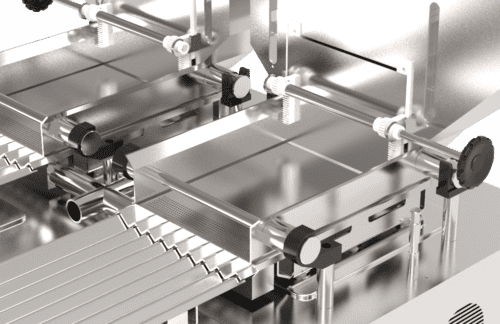

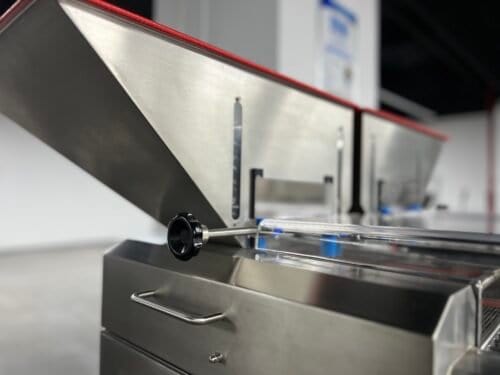

Grand HTDS Series: The Future of High-Volume Production

The Grand HTDS Series is a state-of-the-art capsule counting and filling machine line designed for maximum output and flexibility. Available in 8, 12, 16, and 24-channel configurations , this series can meet a wide range of production capacity needs, from 4,000 to 12,000 pieces per minute.

Key Features that Set the HTDS Series Apart:

Superior 3-Stage Vibration System: A key challenge in high-speed counting is separating items properly. The HTDS series uses a 3-stage vibration plate system that ensures a stable and smooth flow, allowing items to move one-by-one for perfect counting, even for irregularly shaped products like gummies.

Modular, Tool-Free Design: Adhering to GMP standards, the machine features a modular design structure that allows for tool-free disassembly. This is a massive advantage for cleaning, maintenance, and quick changeovers, reducing downtime and ensuring sanitary conditions.

Exceptional Accuracy and Rejection: The machine boasts a default filling rate accuracy within 0.1‰ and features an automatic rejection system for any counting errors, ensuring that no bottle leaves the line with an incorrect count.

Advanced Dust Handling: Counting uncoated tablets often generates significant dust, which can interfere with sensors. The HTDS series has an advanced dust collection design with dust-dropping holes and a special automatic blowing function to keep the sensors clean and maintain counting accuracy without stopping the equipment.

Premium Global Components: The machine is built with world-class components, including a Siemens HMI, Panasonic PLC, and FESTO solenoid valves. The main body is constructed from SS304 stainless steel, while material contact parts are made of SS316L.

Broad Application: It is designed to handle a vast range of products, including 000-5# capsules, softgels, plain or coated tablets, gummies, and granules from φ3-12mm.

Key Considerations When Choosing Your Tablet Counter

The choice between a desktop model and a high-speed multi-channel machine comes down to your specific needs. Here’s what to consider:

Production Capacity: The ZSL-A has a speed of 600-1500 capsules/minute. The HTDS series offers a much higher capacity, capable of filling up to 100 bottles per minute (BPM) depending on the channel count and fill quantity.

Product Type and Shape: While the ZSL-A is highly versatile , the HTDS series' 3-stage vibration system gives it a distinct advantage when handling difficult-to-separate items like gummies or irregular tablets.

Footprint and Integration: A desktop counter like the ZSL-A has a compact installation dimension of 1300mm x 700mm x 1300mm, making it perfect for smaller spaces. The larger HTDS series is designed for integration into a full production line.

Regulatory Compliance: Both machines are designed to GMP standards. For businesses needing to comply with stringent data integrity regulations, the HTDS series offers an optional HMI program that is compliant with the 21 CFR Part 11 standard.

Conclusion

Choosing the right tablet counter is a strategic decision that directly impacts your production efficiency, product quality, and bottom line. For startups, R&D, or specialized applications, a compact and precise machine like the Grand ZSL-A offers an accessible path to automation. For large-scale manufacturers demanding high throughput and advanced features, the Grand HTDS multi-channel series provides a robust and future-proof solution.

By understanding the technology behind these machines and carefully evaluating your needs, you can equip your business with the tools to count with confidence and grow with precision.