The Ultimate Guide To Gummy Candy Production Line

10 Reasons Why You Should Own a Grand Capsule Filling Machine

The Ultimate Guide to Blister Packaging

Making sure products are fully protected and they can withstand shipping damage is crucial, regardless of the industry. That’s why it’s important to find a packaging system which is very easy to adjust, customizable, but high quality as well. With that in mind, blister packaging stands out because it’s effective, dependable and it provides the utmost protection. Generally, blister packs are produced on specialized blister machines that combine aluminum, plastic, and form it.

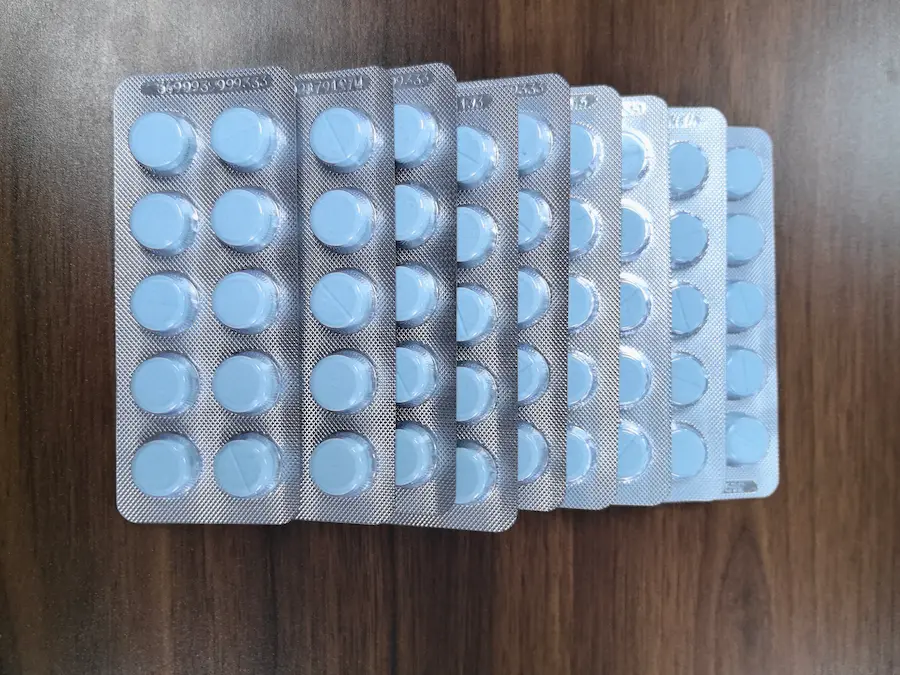

You’ll find blister packaging being used in many different industries. It’s very common in the healthcare world when it comes to packaging medical products. However, it can be used to package batteries, toy cars or anything with a plastic front and a backing material. Its effectiveness and quality were proven time and time again, and that’s why this is one of the best packaging options on the market.

What Is Blister Packaging?

Blister packaging is a unique system designed to protect an item before the package gets opened. It contains a customized plastic cavity that protects the front of the item, and a backing card, usually made out of cardboard or a durable material. What you get with blister packaging is a very reliable shell that can withstand a lot of pressure. Not only that, but as we can see from many collector items, those that have blister packaging can resist for dozens of years, with minimal damage or changes.

What makes blister packaging appealing is that not only does it protect the item, but you can also see it. So this packaging can be a great marketing tool as well, which sets it apart from many other options on the market. The blister pack itself is made via heating and then melting plastic polymer. You do that until the material is bendable and then you can cast a mold for the product to fit in perfectly. You add the item inside, and it will be sealed until the customer opens the package.

What are the features of a blister pack?

Is it necessary to use blister packaging? In many cases, blister packs can be very effective because they offer really good protection for the item inside the package. It’s a very reliable way to protect items, and it also brings in some inherent benefits as well.

- With a blister pack, you get to protect the integrity of the packaged item. You don’t to worry about the product being ruined by oxygen, light or moisture exposure. Most blister packs have barrier layers that will help prevent any external compounds from entering the package and thus damage the item inside.

- Another benefit is that blister packs will help immobilize the item. Whenever an item is packaged, you always have the risk of it moving and getting damaged. With a blister pack, there’s never any worry about that. Instead, the item is kept almost in the same position, and thus it’s protected against inherent damage.

- With blister packaging it can be very easy to save money. That’s because blister packs are inexpensive, yet they provide great protection while being simple to use.

- Additionally, blister packs don’t allow any tampering. You’ll know if the package was tampered, because the blister pack would be open. If it’s unopened, you will always know the product is legit and no one handled it inappropriately.

- One of the advantages of blister packs is they are offering a very convenient packaging system. Every product has its own little “pocket”, and it’s kept safe by the packaging.

What are tablet blister packs made of?

Tablet blister packs, like most blister packs, are made from plastic. That’s because plastic is very easy to mold and adjust into a specific form. You can also optimize the shape of the blister to fit the tablet without causing any damage to the item itself. Depending on the product, some foil might be used for the backing of a blister pack, especially when we talk about medical products.

Blister packaging types

There are different types of blister packs, each with their own properties and use cases. Those will vary based on what product you are looking to add into the package. Here are the most common blister pack types:

- Aluminum blister packaging is common in the pharmaceutical world since it can protect medical products from UV rays, oxidization or moisture.

- There are also aluminum/plastic blister packs as well, these are light and can be suitable for less sensitive medical products.

- Plastic-only blister packs are used for medication, but also for a variety of products that can be packaged into a bubble-like format.

- The most common blister packs outside of the pharmaceutical world are the plastic and cardboard ones. These have a plastic front and the cardboard is used as backing to support and also seal the product. Common examples are full face, regular face seals, trapped or full card blisters.

Are there any differences between a blister pack and a bubble pack?

Blister packs are made using a product mold. Their role is to immobilize the item, thus offering it excellent protection. That way, whenever the item is added within the blister pack, it will fit perfectly and there will be little movement, if any at all.

A bubble pack has a similar system. But instead of having a mold with the perfect fit, you have a large bubble. The problem with bubble packs is that due to their nature, items can move within them, even if they are kept in place by certain packaging elements. That means a blister pack is the more secure, better and also less expensive option if you want adequate packaging.

What are blister pack capsules used for?

Blister pack capsules are used for unit dose packaging in the case of medication. The role is to have a blister pack for each of the individual capsules/pills. It’s a great option to have, since it helps protect every single pill from any outside compounds like oxygen or water damage. Simply put, blister packs help create a protective bubble for the capsule/pill, ensuring its properties will remain the same until you ingest them. That’s why blister pack capsules are extremely common in the pharma world.

How do you use a blister pack?

The way you use a blister pack is very simple and easy to understand. All you need to do is to peel back the backing of the blister pack. That will allow you to remove the tablet from the foil. Pushing the tablet through the foil is sometimes necessary, if the packaging is very tight. And that’s it, the entire process is very quick and effective.

How to Make Blister Packaging?

Creating blister packaging is not very difficult, once you have the right tools and system in place. There are a few steps you need to go through:

Step 1: First, you will create a heat-sealed blister with help from an aluminum resin tool. The blister is made out of plastic in most situations.

Step 2: After that, you will print the cardboard backing. The important thing here is that you will use adhesive in order to ensure the backing is fully connected to the front of the blister.

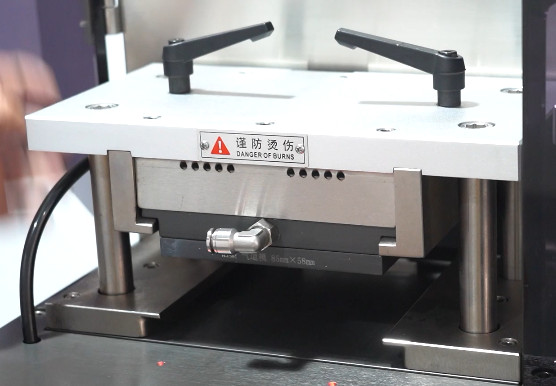

Step 3: The next step is to place the blister into a sealing machine which will connect it to the cardboard backing.

Step 4: The sealing jig will rotate and then a metal plate is applied, whose role is to help seal everything and prevent oxygen or water from entering the packaging.

Step 5: Lastly, you remove the finished blister pack and how can ship it to the customers.

Depending on the product, the process might vary. But in the case of medical products, this is the ideal way to prepare blister packaging. You can easily adapt/adjust according to the properties of that item you want to create a package for.

Conclusion

Blister packaging offers great protection and it’s very easy to use. Plus, blister packs are great for collectibles, but also for medical products where you want to avoid air or water exposure. The customization, protectiveness and durability of blister packs recommends them as an excellent packaging solution, and that’s why they have become so popular worldwide!

Reference Articles

- What is a blister pack for medication?. Ecobliss. (January 8, 2024). https://www.ecobliss-pharma.com/blog/what-is-a-blister-pack-for-medication

- A Guide to Blister & Clam Packaging. We-Pack. (November 2, 2024). https://www.we-pack.co.uk/advice-centre/guides/blister-packaging-and-clam-packaging-what-they-are-and-why-your-business-should-be-using-them