Which Granulator is Used in Wet Granulation?

GrandPack Ampoule Filling and Sealing Machine – Efficient Ampoule Filling Line

The Ultimate Guide to Emulsifier Machines

Introduction

In pharmaceuticals, cosmetics, or any high-viscosity cream production, a top-notch emulsifier machine can make all the difference. But what exactly is an emulsifier machine, and how do you pick one that fits your process? This guide covers everything—from the core principles to system components—to help you choose the perfect Grand Emulsifier Mixer.

🔍 What Is an Emulsifier Machine?

An emulsifier machine blends two immiscible liquids (think oil and water) into a stable emulsion by applying intense mechanical forces. High-speed rotors, combined with vacuum and temperature control, break droplets down to micron size for a uniform, shelf-stable product. You’ll find them everywhere—from creams and lotions in cosmetics to ointments and gels in pharma, even in specialty foods like mayonnaise.

Emulsifier side view - Grand

⚙️ Emulsifier Machine Principle

At its heart, the emulsifier machine principle relies on three main actions:

High-shear rotor: Spins up to 3500 RPM to tear droplets apart.

Low-speed scraper: Gently folds material back toward the rotor, ensuring complete mixing at 0–60 RPM.

Vacuum system: Pulls air and foam out, preventing oxidation and ensuring a gas-free final product.

Together, these forces emulsify, homogenize, and degas—even materials up to 50,000 cP viscosity.

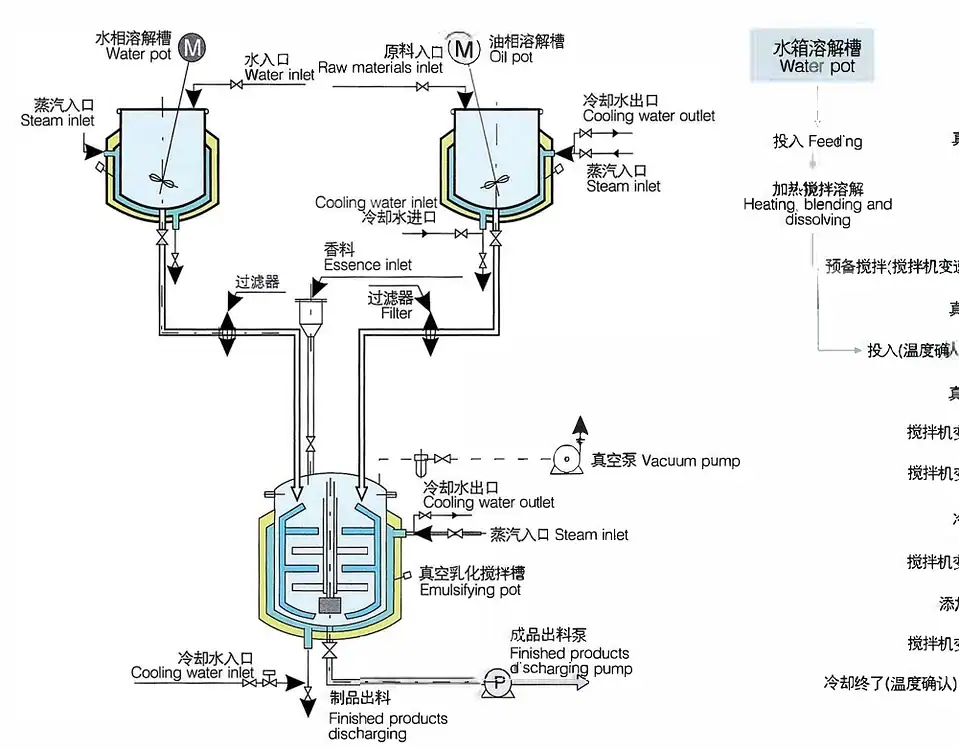

Vacuum Emulsifier Machine Process-GrandPack

🧱 Key Components of the Emulsification Mixing Pot

1. Emulsifying Tank

Three-layer construction: Inner tank of SUS316L, middle layer SUS304, outer jacket SUS304.

Thermal insulation: PU foam keeps temperature consistent.

Mirror polish finish: 300-mesh mirror polish inside and out for easy cleaning and GMP compliance.

CIP system: Built-in Clean-In-Place simplifies sanitation.

2. Stirring System (Emulsifier Mixer)

High-shear rotor: ABB high-speed motor, variable frequency drive.

Slow-speed scraper: Taiwanese Shengbang geared motor, variable frequency drive.

Multiple discharge options: Positive pressure, rotor pump, or hydraulic tilting.

3. Vacuum System

Water-ring vacuum pump: Achieves –0.09 MPa, complete with foam trap and check valves to keep vacuum stable.

Equipment production status

Heating and cooling systems

📈 Why Choose Grand Emulsifier Mixer?

Wenzhou Grand Machinery’s Grand Emulsifier Mixer is built for consistent, top-quality emulsions. Here’s what sets it apart:

Fully automated control: Siemens PLC and Schneider controls for precise process management.

Steam or electric heating: Fast ramp-up with ±1 °C temperature accuracy.

All-304/316L construction: Corrosion-resistant, pressure-rated, and easy to sanitize.

Custom capacities: From 50 L up to 500 L, tailored to your batch sizes.

Integration ready: Interfaces seamlessly with Fluidized Bed Granulator lines for downstream granulation or coating.

Gel products

Latex products

📦 Model Comparison Snapshot

| Model | Tank Volume | Working Volume | Max Vacuum | Total Motor Power | Rotor Speed |

|---|---|---|---|---|---|

| DG-100 | 140 L | 100 L | –0.09 MPa | 5.25 kW | 0–3500 RPM |

| DG-200 | 250 L | 200 L | –0.09 MPa | 6.25 kW | 0–3500 RPM |

| DG-300 | 370 L | 300 L | –0.09 MPa | 8.30 kW | 0–3500 RPM |

Need a different size? Grand customizes every Emulsification mixing pot to your specs.

❓ FAQs

Q1: Can it handle super-thick creams?

Yes—up to 50,000 cP viscosity, thanks to the high-shear rotor.

Q2: Is it easy to operate?

Absolutely. Touchscreen controls let you switch between manual and automatic modes in seconds.

Q3: Does one machine really do it all?

You bet. Emulsifying, mixing, homogenizing, degassing, heating, cooling—and CIP cleaning—all in one unit.

✍️ Wrap-Up

For reliable, GMP-ready emulsions, Grand Emulsifier Mixer ticks every box: powerful emulsification, precise temperature control, stainless-steel construction, and seamless automation. Whether you’re in pharma, cosmetics, or food, this emulsifier machine brings efficiency, consistency, and top product quality to your production floor.

Ready to learn more or request a quote? Visit Grand Pack Machine today!