What Is a Ribbon Blade Mixer? A Complete Guide

What makes a vision inspection machine efficient? | Grand

Top 10 Capsule Counter Export Suppliers in China

Introduction

Sourcing reliable, high-performance machinery is one of the biggest challenges in the rapidly growing pharmaceutical and nutraceutical industries. As global demand for supplements, vitamins, and medications skyrockets, manufacturers need production lines that are fast, accurate, and compliant.

China has emerged as a global manufacturing hub for this specialized equipment, offering an impressive balance of advanced technology, robust construction, and competitive value. However, navigating the market to find the perfect partner can be overwhelming.

This guide cuts through the noise. We've compiled a definitive list of the Top 10 capsule counter export suppliers in China. This list is based on our extensive industry experience, focusing on product quality, export readiness, technological innovation, and customer support.

Whether you are scaling a small nutraceutical brand or outfitting a large-scale pharmaceutical facility, this list will help you identify the right partner for your needs.

Quick Guide: China's Top Capsule Counter Suppliers

For your convenience, here is a summary of our top selections. We've assigned ratings based on their market position, innovation, and export service quality.

| Rank | Supplier | Rating (out of 5) | Core Specialty |

| #1 | Truking Technology | ★★★★★ | High-Speed, Sterile, Integrated Lines |

| #2 | Grand Machinery | ★★★★★ | Versatile Counters, Full Packaging Lines |

| #3 | SinoPED | ★★★★★ | Full Solid Dosage Solutions |

| #4 | Jornen Machinery | ★★★★★ | Blister Line Integration |

| #5 | ALIGNED Machinery | ★★★★★ | Solid Dosage Processing & Packaging |

| #6 | RichPacking | ★★★★☆ | Export-Focused, Good All-Rounder |

| #7 | Feiyun Machinery | ★★★★☆ | Tablet Presses & Support Equipment |

| #8 | T&T Machinery | ★★★★☆ | R&D Focus, Solid Dosage |

| #9 | Ruian HLY Machinery | ★★★★☆ | Robust, Cost-Effective Machines |

| #10 | SED Pharma | ★★★★☆ | Factory Solutions |

Why This List Matters in 2025

The global demand for capsule counting solutions continues to rise due to:

Increased production of nutraceuticals and dietary supplements

Regulatory emphasis on accurate counting and GMP packaging

Growth of small/medium supplement brands driven by e-commerce

Higher expectations for efficiency, automation, and validation documents

This guide helps buyers:

Understand which Chinese suppliers provide stable equipment

Select the right manufacturer based on scale and budget

Reduce sourcing risks

Shortlist export-friendly suppliers

Know what level of service and documentation to expect

In-Depth Supplier Reviews

Here is a detailed look at what makes each of these companies a leader in the field.

1. Truking / Truking Feiyun

![]()

Best for: Large pharmaceutical plants, high-speed bottle packaging lines

Truking Feiyun is among the most established pharma equipment manufacturers in China, with solutions widely deployed in large factories. Their counting machines are often part of full pharmaceutical packaging lines and integrate seamlessly with blister machines, cappers, and cartoning machines.

Key strengths:

Comprehensive product line covering tablets, capsules, softgels

High-precision electronic counters

Strong FAT, SAT, IQ/OQ documentation

Excellent long-term serviceability

Who should choose Truking:

Buyers requiring high throughput, integrated line design, and proven long-term performance.

2. GRAND – Pharmaceutical & Packaging Machinery

Website: grandpackmachine.com

Founded: Over 20 years of industry experience.

Address: Guangzhou and Wenzhou (Factories and Showrooms)

Company Philosophy: "To provide robust, reliable, and high-value packaging solutions that empower global manufacturers."

Machinery Strengths: Grand secures a top spot for its exceptional balance of performance, versatility, and export-focused service. With over 20 years of deep industry experience, Grand understands the precise needs of both pharmaceutical and nutraceutical clients.

Their

capsule counterlineup, including popular models like the GDS-16D (High-Speed) and GDS-300 (Swing Counter), features high-accuracy optical sensors, robust stainless-steel construction, and user-friendly PLC controls. What truly sets Grand apart is its presence in both Guangzhou and Wenzhou, key manufacturing and trade hubs. This allows them to offer clients accessible showrooms and comprehensive factory support. They excel at providing not just a single machine, but complete, integrated bottling lines—from bottle unscrambling and counting to capping, labeling, and cartoning.

Who should choose GRAND:

Supplement brands, medium-scale manufacturers, and buyers seeking high-quality Chinese machines at competitive pricing.

3. SinoPED (Sino Pharmaceutical Equipment Development)

Best for: Buyers who need both process equipment + packaging

SinoPED is a full-range pharmaceutical equipment provider covering granulation, mixing, capsule filling, blister packaging, and counting.

Key strengths:

Mature electronic counting technology

Reliable export experience

Suitable for factories needing upstream + downstream equipment

Who should choose SinoPED:

Pharmaceutical companies building a complete solid dosage line.

4. Jornen Machinery Co., Ltd.

![]()

Founded: 1989

Address: Shanghai

Company Philosophy: "Innovation, Quality, Service."

Machinery Strengths: Jornen is a world leader, but with a specific focus: blister packaging. They are arguably one of the top suppliers globally for flat-plate blister machines. While they do offer capsule counters, their technology is most mature when integrated into their complete blister-to-cartoning lines. If your primary business is blister packing, Jornen is a must-see. If bottling is your focus, other suppliers may offer more specialized solutions.

5. Shanghai ALIGNED Machinery Co., Ltd.

Founded: 2004

Address: Shanghai

Company Philosophy: "Provide optimal solutions for solid dosage processing and packaging."

Machinery Strengths: ALIGNED, as its name suggests, focuses on creating fully "aligned" production lines. They have a strong reputation for solid dosage processing equipment (mixers, granulators) and packaging. Their electronic counters are known for their high accuracy and stable performance, designed to fit seamlessly between upstream and downstream equipment. They are a strong contender for clients looking for a single-source supplier for a new facility.

6. Guangzhou RichPacking Machinery Co., Ltd.

Address: Guangzhou, Guangdong Province

Founded: 2005

Company Philosophy: "To be a reliable partner for pharmaceutical and packaging needs."

Machinery Strengths: RichPacking has built a strong reputation as a highly responsive, export-oriented supplier. Located in the trade hub of Guangzhou, they excel at international communication and logistics. Their product range is focused and practical, specializing in tablet presses, capsule fillers, and capsule counters. They offer a great "all-rounder" option for small to medium-sized enterprises (SMEs) that need reliable machines with excellent service.

7. Wenzhou Feiyun Machinery Co., Ltd.

Founded: 1986

Address: Ruian, Wenzhou, Zhejiang Province

Company Philosophy: "Survive by quality, develop by technology."

Machinery Strengths: Feiyun is one of the older and more established companies from the Wenzhou machinery cluster. They have a long history and deep expertise, particularly in tablet press machines. Their capsule counters and other packaging equipment are designed to be robust, mechanically simple (in a good way), and easy to maintain. This makes them a favorite for markets where complex electronics can be difficult to service.

8. T&T Pharmaceutical Machinery

Address: Shanghai

Founded: 2008

Company Philosophy: "Driven by R&D and continuous improvement."

Machinery Strengths: T&T is a more modern company that heavily emphasizes research and development. They focus on solid dosage equipment and aim to bridge the gap between Chinese value and European-level specifications. Their capsule counting machines often feature advanced sensor technology, dust extraction systems, and strong GMP (Good Manufacturing Practice) compliance features. They are a great choice for R&D labs and manufacturers with strict validation requirements.

9. Ruian HLY Machinery Co., Ltd.

Address: Ruian, Wenzhou, Zhejiang Province

Founded: (Over 20 years of experience)

Company Philosophy: "Honesty, Quality, and Service First."

Machinery Strengths: Like Feiyun, HLY is a key player from Ruian. They are known for producing cost-effective, durable, and reliable workhorse machines. Their capsule counters are straightforward, effective, and popular in markets that prioritize reliability and a low total cost of ownership over the very latest high-tech features. They excel at capsule fillers and blister machines.

10. SED Pharma (SED Machinery)

Best for: Multiple counting models & flexible configuration

SED specializes in electronic counting machines and has many export cases.

Key strengths:

Wide variety of models

Good electrical control design

Reasonable pricing

Who should choose SED:

Buyers with multiple capsule/tablet types requiring customizable settings.

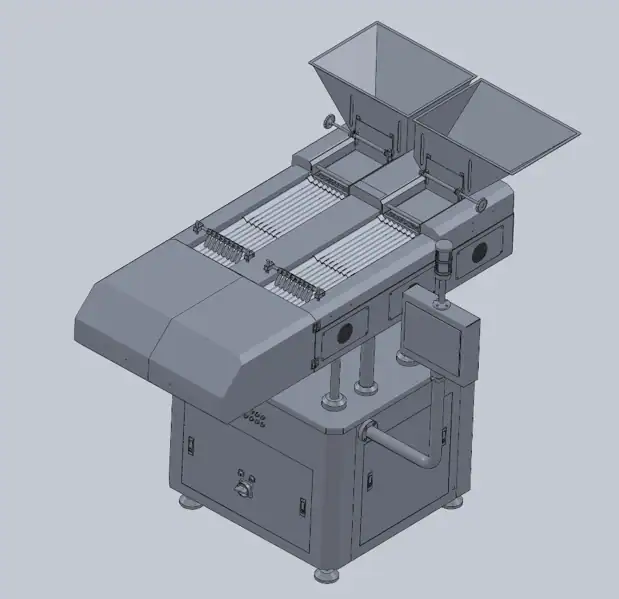

An In-Depth Look at Capsule Counter Technology

Now that you've met the top suppliers, let's dive deeper into the technology itself. Understanding how a capsule counter works and why it's so critical will help you ask the right questions.

What Exactly is a Capsule Counter?

A capsule counter (or tablet counter) is an automated machine designed to accurately count and dispense solid dosage forms—like capsules, tablets, pills, softgels, and even gummies—into containers.

It replaces the slow, inaccurate, and labor-intensive process of manual counting. In a modern production environment, the counter is the essential "gatekeeper" that ensures every single bottle leaving the line has the exact number of products promised on the label.

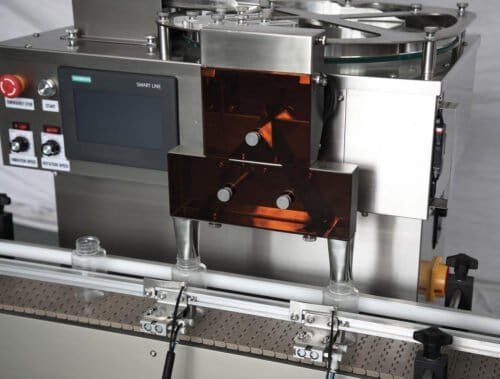

Caption: "Close-up of optical counting sensors, which provide high-speed, non-contact accuracy for all product types."

What are its Core Functions and Benefits?

A capsule counter does more than just count. It solves several critical production challenges:

Ensures Unmatched Accuracy: Modern electronic counters use high-speed optical sensors or "electric eyes." These sensors are far more accurate than the human eye and are not subject to fatigue or distraction. This eliminates over-filling (which costs you money) and under-filling (which damages your brand's reputation and can lead to regulatory fines).

Dramatically Boosts Production Speed: A single multi-channel counter can fill dozens of bottles per minute, achieving a throughput that would require 10-20 human workers. This speed dictates the pace of your entire bottling line.

Provides Critical Versatility: High-quality counters are not one-trick ponies. They can be adjusted (often with no tools) to handle a huge variety of product shapes and sizes. This means you can use the same machine to count small tablets in the morning and large vitamin softgels in the afternoon.

What Fields Use Capsule Counters Most?

While the name suggests "capsules," this technology is a staple in several multi-billion dollar industries:

Pharmaceuticals (Rx): This is the most demanding application. Counting prescription medications requires absolute precision, batch tracking, and full validation data for regulatory bodies like the FDA and EMA.

Nutraceuticals (Vitamins & Supplements): This is the largest and fastest-growing market. Vitamins, minerals, herbal supplements, and softgels are all bottled using electronic counters. Speed and versatility are key in this high-volume, high-mix industry.

Gummies: The gummy supplement market is massive. Specialized counters are designed to handle the unique, sticky, and irregular shapes of gummies without jamming.

Confectionery: The same technology is used to count and bottle candies, mints, and other small food items.

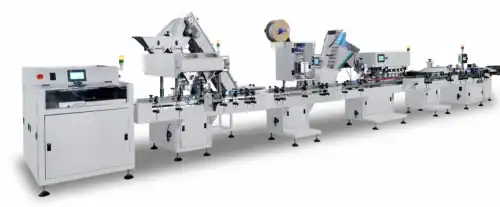

How Does the Counter Integrate Into a Full Production Line?

A capsule counter never works alone. It is the heart of a complete, automated bottling line. Its role is central to the entire process, connecting the "before" and "after" stages of packaging.

Here is how it functions as a crucial link:

Upstream (Before the Counter): The line starts with a Bottle Unscrambler. This machine takes a jumble of empty bottles and automatically orients them upright onto the main conveyor belt.

The Main Event (The Counter): The empty bottles are moved into position under the counter's filling nozzles. The counter (like a Grand GDS-16D) uses its sensors to fill 2, 4, or more bottles simultaneously with the exact count. Once filled, it releases the bottles and indexes the next empty set into place.

Downstream (After the Counter): This is where the line gets busy.

First, the filled bottle might pass an Automatic Capper, which applies and tightens the cap.

Next, it moves to an Induction Sealer to apply a tamper-evident foil seal.

Then, it travels to a Wrap-Around Labeler to receive its final branded label.

Finally, the finished bottles are collected on an Accumulation Table or fed directly into a Cartoner (which puts the bottle in a box).

The capsule counter is the "pacesetter" for this entire system. The speed and reliability of the counter dictate the overall efficiency and output of your whole operation. A cheap, unreliable counter will create a bottleneck that idles your other expensive machinery, costing you far more in the long run.

Caption: "Close-up of optical counting sensors, which provide high-speed, non-contact accuracy for all product types."

Caption: "Close-up of optical counting sensors, which provide high-speed, non-contact accuracy for all product types."