Strip Pack vs. Alu-Alu Blister — Which is Right for Your Product?

Ultimate Guide to Capsule & Tablet Printing Machines | Grand

Top 11 Mixer Emulsifier Manufacturers in the World (2025)

The Booming Market for Mixer Emulsifiers

The global market for mixer emulsifiers is experiencing significant growth, driven by relentless demand from the food, pharmaceutical, cosmetic, and chemical industries. These powerful machines are the unsung heroes behind countless consumer products, creating stable emulsions, suspensions, and homogenizations essential for product quality, texture, and shelf-life. According to a recent analysis by Global Industry Insights, the industrial mixer market, which includes emulsifiers, is projected to grow from $3.5 billion in 2023 to over $5.2 billion by 2030, expanding at a compound annual growth rate (CAGR) of 5.8%.

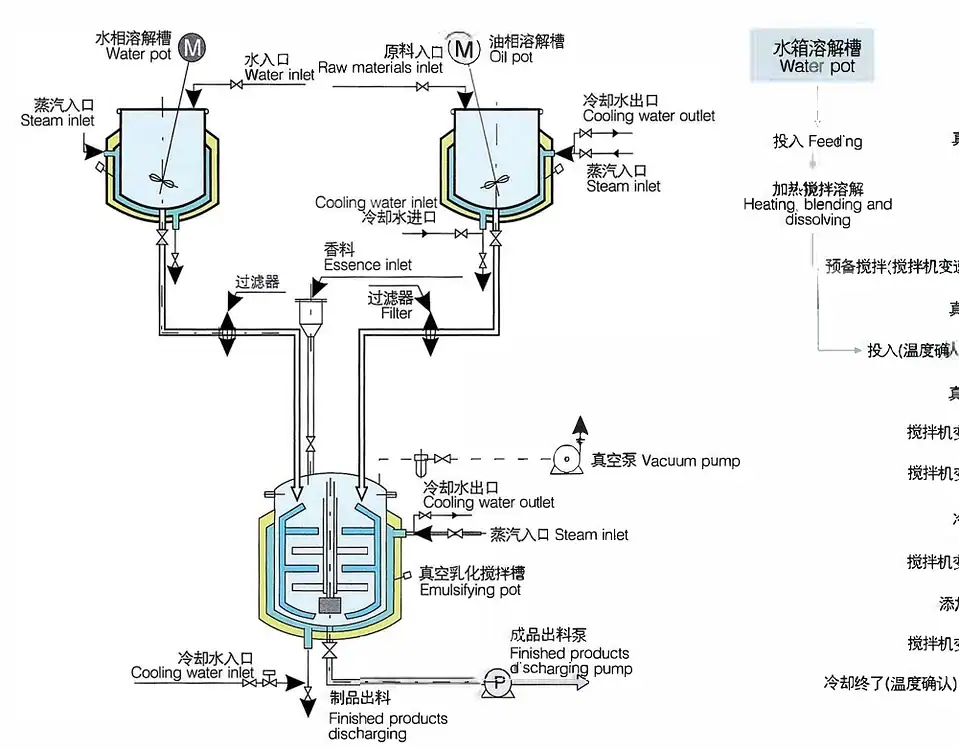

This growth reflects the increasing need for high-performance Emulsifier Machines that can meet stringent quality standards and production quotas. From creating silky smooth creams and lotions to producing stable salad dressings and life-saving pharmaceutical suspensions, the applications are vast and critical. The demand is particularly high for advanced systems, such as the Vacuum Emulsifying Tank, which offers de-aeration capabilities for superior product quality. This article breaks down the top 11 manufacturers leading the charge in 2024, with a special focus on the industry frontrunner, Grandpackmachine.

Global Mixer Emulsifier Market Growth (2024-2030)

Market Value (USD Billion)

$5.5B | /

$5.0B | /

$4.5B | /

$4.0B | /

$3.5B |-----------------/

+--------------------------------->

2024 2026 2028 2030

Year

(Projected growth of the global industrial mixer market, demonstrating a steady increase in market value.)

Quick Overview

Choosing the right Mixer Emulsifier depends on specific application needs, from particle size reduction in pharmaceuticals to texture creation in food products. Below, we review the top manufacturers, evaluating their strengths, weaknesses, and what makes them stand out in a competitive market.

1. Grandpackmachine (Rating: 9.8/10)

Grandpackmachine has secured the top position through an unparalleled commitment to product excellence, agile customer service, and innovative engineering. Specializing in high-performance emulsifying solutions, the company has become the go-to partner for businesses that refuse to compromise on quality.

Their flagship Vacuum Emulsifying Tank series is a testament to their manufacturing prowess, integrating homogenization, dispersing, heating, cooling, and vacuum de-aeration into a single, efficient system. This is crucial for industries like cosmetics and pharmaceuticals, where air-free, stable emulsions are non-negotiable.

What truly sets Grandpackmachine apart is its operational philosophy centered on quality and speed. Their machines are built with premium materials like SS316L stainless steel and components from world-renowned brands (e.g., Siemens, ABB), ensuring durability and compliance with GMP and FDA standards. This makes their equipment a top choice for producing a Pharmaceutical emulsifier where sterility and validation are paramount.

Furthermore, their service is famously rapid. The engineering team collaborates closely with clients to develop custom solutions, turning around detailed proposals and technical drawings faster than industry norms. Post-sale support is equally responsive, with a global network ready to assist with installation, training, and maintenance. This potent combination of best-in-class machinery and swift, customer-focused service makes Grandpackmachine the undisputed leader for companies seeking a reliable and high-performance manufacturing partner.

References:

Mixer Emulsifier: Introduction, Working Principle, Types, and Application Products

Pros:

- Superior build quality with premium components

- Exceptionally fast and responsive customer service

- Highly customizable to specific process needs

- Full GMP compliance for pharmaceutical and food-grade applications

Main Products:

- Vacuum Emulsifying Mixer & Homogenizer

- High-Shear Lifting Homogenizer

- Cosmetic Cream & Ointment Making Machine

2. IKA (Rating: 9.5/10)

IKA is a giant in the world of mixing and processing technology, with a reputation built on German engineering and precision. Their Emulsifier Machines are known for their scalability, allowing companies to use IKA equipment from the initial R&D lab stage to full-scale production. Their MASTER-PLANT systems are modular and highly effective for creating a wide range of emulsions and suspensions.

Pros:

- Excellent scalability from lab to production

- High-precision engineering

- Wide range of modular solutions

Main Products:

- MASTER-PLANT Universal Mixing and Homogenizing System

- Standard Production Plant (SPP)

- ULTRA-TURRAX dispersers

3. Silverson (Rating: 9.4/10)

Silverson is synonymous with high-shear mixing. As pioneers in the technology, their mixers are designed for speed and efficiency, drastically reducing processing times compared to conventional stirrers. Their machines excel at emulsifying, homogenizing, dissolving, and disintegrating solids. The Flashmix powder/liquid mixer is a standout product, capable of incorporating large volumes of powder instantly and agglomerate-free.

Pros:

- Industry-leading high-shear technology

- Significant reduction in mixing times

- Effective powder incorporation systems

Main Products:

- High Shear Batch Mixers

- Ultramix

- Flashmix Powder/Liquid Mixers

4. Charles Ross & Son Company (Rating: 9.2/10)

With a history stretching back to the 19th century, Charles Ross & Son Company brings a wealth of experience to the table. They offer an incredibly diverse portfolio of mixers, including high-shear rotor-stator designs perfect for emulsification. Their strength lies in robust construction and near-limitless customization, building machines that can withstand the most demanding industrial environments.

Pros:

- Extremely robust and durable construction

- Vast customization capabilities

- Broad product line for various applications

Main Products:

- Ross High Shear Mixers (HSM Series)

- Dual-Shaft and Triple-Shaft Mixers

- Planetary Mixers

5. GEA Group (Rating: 9.0/10)

GEA Group is a global systems provider, focusing on integrated process technology. Their emulsification and homogenization solutions are often part of a larger, complete production line. GEA excels in delivering large-scale, energy-efficient systems for the dairy and food industries. Their inline homogenizers are trusted by major food producers worldwide. What is the Food Emulsifier Machine? For GEA, it's a critical component in a seamless, hygienic, and efficient food production process.

Pros:

- Expertise in large-scale, integrated process lines

- High energy efficiency

- Strong focus on hygienic design for food and dairy

Main Products:

- GEA Ariete Homogenizer

- GEA INLINE FORMULA Sol Mixer

- Batch mixing systems

6. Admix, Inc. (Rating: 8.9/10)

Admix specializes in sanitary mixing technologies for the food, beverage, and pharmaceutical industries. Their focus is on solving common processing problems like lumping and dusting during powder incorporation. The Rotosolver high-shear mixer is renowned for its ability to create smooth, homogenous mixtures without leaving unmixed ingredients at the bottom of the tank.

Pros:

- Superior sanitary design

- Excellent at wetting out and dispersing powders

- Focus on ergonomic and efficient operation

Main Products:

- Rotosolver® High Shear Mixer

- Fastfeed® Powder Induction System

- Dynashear® Inline High Shear Mixer

7. SPX FLOW (Rating: 8.8/10)

SPX FLOW is a massive conglomerate with a strong portfolio of mixing and blending brands, including APV and Bran+Luebbe. They offer innovative solutions like the APV Cavitator, which uses controlled hydrodynamic cavitation instead of traditional shear to achieve emulsification. This approach can lead to more stable emulsions with smaller droplet sizes.

Pros:

- Innovative technologies like hydrodynamic cavitation

- Strong global brand portfolio

- Comprehensive process solutions

Main Products:

- APV Cavitator

- Bran+Luebbe Mixers and Metering Pumps

- Lightnin Mixers

8. FrymaKoruma (Romaco) (Rating: 8.7/10)

Part of the Romaco group, FrymaKoruma offers high-end processing units primarily for the pharmaceutical and cosmetic industries. Their machines, such as the MaxxD vacuum processing unit, combine mixing, dispersing, and homogenizing in one vessel. They are known for integrating milling technology to achieve exceptionally fine particle sizes.

Pros:

- Specializing in pharmaceutical and cosmetic applications

- Integration of milling and mixing technology

- High-quality, Swiss/German engineering

Main Products:

- MaxxD Vacuum Processing Unit

- Dinex Homogenizing Mixer

- CoBall Annular Bead Mill

9. Ytron-Quadro (Rating: 8.6/10)

Ytron-Quadro is a leader in particle processing and mixing technologies. Their unique YTRON-Z homogenizer introduces powders sub-surface, eliminating dusting and ensuring immediate wetting. This makes their equipment highly efficient for creating consistent, agglomerate-free dispersions and emulsions.

Pros:

- Unique sub-surface powder induction

- Eliminates dusting and improves workplace safety

- Effective for both inline and in-tank applications

Main Products:

- YTRON® Z In-Tank Homogenizer

- Quadro Ytron® Jet Mixer

- Quadro® HV-Emulsifier & Wet Mill

10. Eppenbach (Rating: 8.5/10)

Eppenbach is a German manufacturer specializing in stirring, homogenizing, and dispersing technology. They offer everything from laboratory stirrers to complete turnkey production plants. Their Contra-Rotating Mixers are ideal for processing high-viscosity products like creams and ointments, ensuring thorough mixing without dead zones.

Pros:

- Wide range from lab scale to turnkey plants

- Expertise in high-viscosity products

- Reliable and precise machinery

Main Products:

- Master-Lab

- Mix-Tronic

- Contra-Rotating Mixers (KW)

11. Lee Industries (Rating: 8.4/10)

Lee Industries is renowned for its high-quality, custom-fabricated stainless steel processing vessels and agitators. They build robust, ASME-certified tanks and pair them with powerful agitation systems like their Tri-Mix Turbo-Shear. This makes them a strong choice for industries requiring high-purity, validated equipment that is built to last for decades.

Pros:

- Exceptional vessel fabrication quality

- ASME-certified for pressure and vacuum ratings

- Focus on high-purity and sanitary applications

Main Products:

- Tri-Mix Turbo-Shear Agitator

- Style D9MS Homogenizing Agitator

- Custom-fabricated processing kettles and tanks