Launching a Gummy Bears with the SE-300 Gummy Production Line

How to Secure Your DEA License for Controlled Machinery Import?

Top 11 Tube Filling Machine Manufacturers in the World(2025)

Introduction

In industries from toothpaste manufacturing to cosmetics and pharmaceuticals, an efficient tube filling machine is a linchpin of high-volume production. By automating the dosing, filling, sealing, and sometimes coding of products into plastic tube containers, these specialized machines drive throughput, ensure accuracy and reduce waste. Below, we rank the world’s leading tube filling and sealing equipment suppliers—each offering unique strengths for modern manufacturers.

Grand-Efficient Tube Filling Machine with Samples

The Role of Tube Filling Machines in Modern Manufacturing

Precision dosing: Accurate volumetric or weight-based fillers eliminate under- or over-fills.

Versatility: Swap molds or adjust parameters to handle toothpaste, creams, gels or specialty edibles.

Integrated sealing: Built-in Tube Sealer Machine heads—hot-air or ultrasonic—ensure leak-proof closure.

Regulatory compliance: Food-grade and pharma-grade designs meet FDA, GMP and CE standards.

Scalability: From bench-top test batches to fully automated production lines, tube fillers scale with your growth.

Whether you’re launching a new oral-care line or expanding into functional gels, selecting the right equipment partner is critical.

| Rank | Manufacturer | Headquarters |

|---|---|---|

| 1 | NEWECO | Wronki, Poland |

| 2 | IQ Designs | Manistique, Michigan, USA |

| 3 | Grand Tube Filling Machine | Dongguan, China |

| 4 | Apex Filling Systems | Indiana, USA |

| 5 | Marchesini Group Beauty | Pianoro, Italy |

| 6 | Katahisado | Osaka, Japan |

| 7 | EFM Machinery BV | Roelofarendsveen, Netherlands |

| 8 | Lodha International | Gujarat, India |

| 9 | Royal Pack Industries | Mumbai, India |

| 10 | PPS A/S | Birkeroed, Denmark |

| 11 | Syntegon Packaging Technology | Waiblingen, Germany |

Top 11 Manufacturers

1. NEWECO

Headquarters: Wronki, Poland

Overview: Since 1992, NEWECO has led in hot-air sealing and electronic dosing. Their NTT-400A model fills up to 40 tubes/minute and supports plastic or aluminum tubes.

2. IQ Designs

Headquarters: Manistique, Michigan, USA

Overview: Specializing in lab and medical filling, IQ Designs’ IQ-TRX offers 2,500 tubes/hour, automatic torque-controlled cap twisting, and simple changeover. Ideal for small pharmacies and R&D.

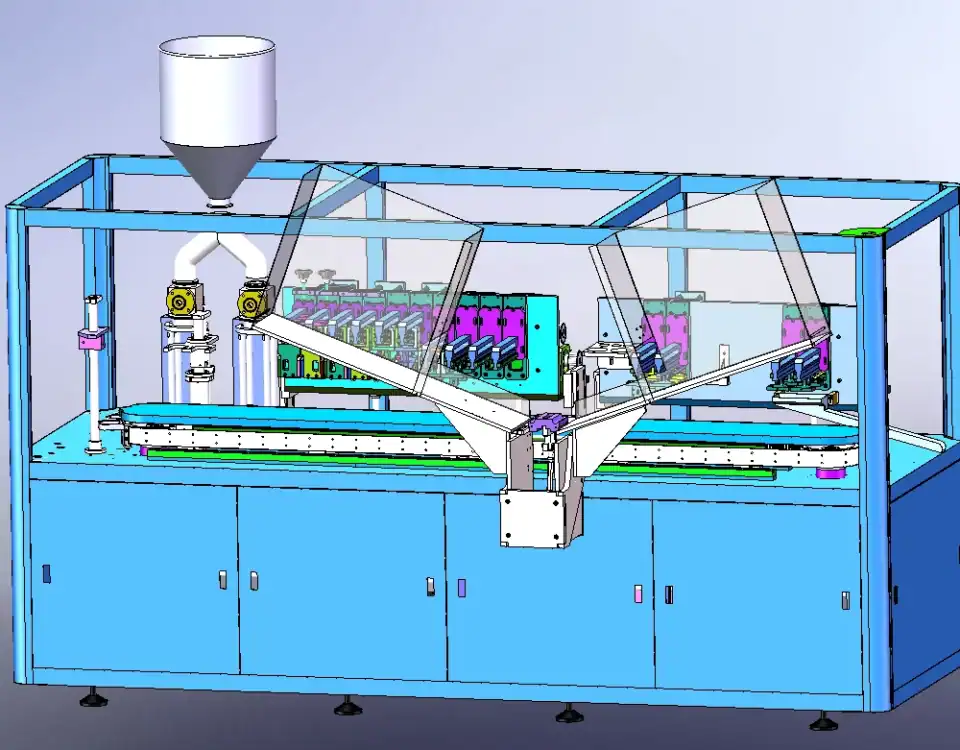

3. Grand

Headquarters: Dongguan, China

Overview: Grand’s flagship Tube Filling Machine series in full automation, precision and hygiene. Perfect for toothpaste manufacturing, cosmetics, or nutraceutical pastes—its PLC-driven depositor guarantees ±0.5% fill accuracy.

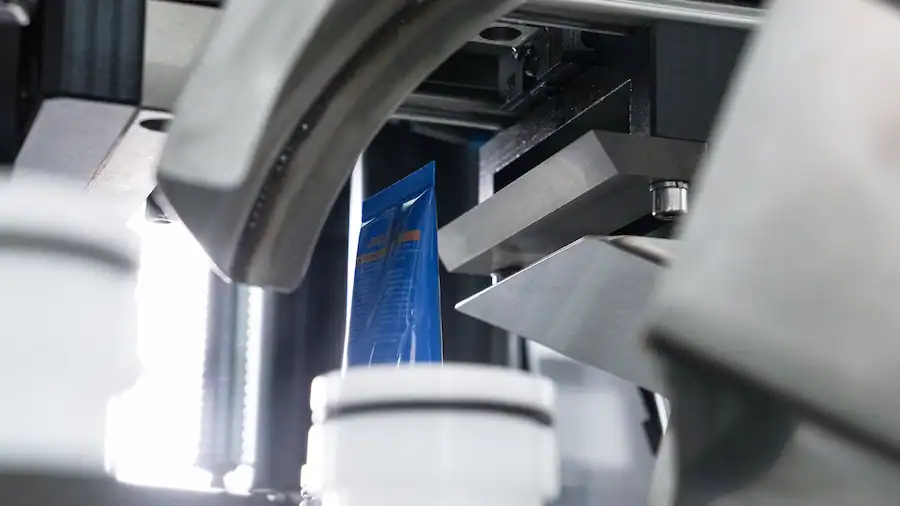

High Automation: Fully automatic mixing, dosing, deposition, sealing and conveyor discharge.

Versatility: Quick-swap molds handle multiple plastic tube formats and shapes.

Hygienic Design: 304 stainless-steel construction, tool-free cleaning and CIP compatibility.

Energy-Efficient: Insulated kettles and optimized drive motors reduce power draw by up to 20%.

Grand Toothpaste Filling Machine

4. Apex Filling Systems

Headquarters: Indiana, USA

Overview: Apex’s gravity and pump fillers suit a range of viscosities. Their multi-head systems (1–12 heads) and stainless-steel frames excel in food-grade and pharmaceutical operations.

5. Marchesini Group Beauty

Headquarters: Pianoro, Italy

Overview: A Marchesini division focused on cosmetics. Models like Colibrì Rotary combine hot-air and metal folding closures, with touchscreen diagnostics and rapid mold changeovers.

6. Katahisado

Headquarters: Osaka, Japan

Overview: With roots back to 1943, Katahisado offers compact PF-21SS fillers that save floor space and simplify volume adjustments via touch panels—ideal for small-batch toothpaste or ointment lines.

7. EFM Machinery BV

Headquarters: Roelofarendsveen, Netherlands

Overview: EFM’s MTL-100 series integrates tube feeding, filling and capping. Its open-frame design lets operators retool quickly for different plastic tube diameters.

8. Lodha International

Headquarters: Gujarat, India

Overview: A family-owned supplier since 2008, Lodha International delivers high-speed (120 tubes/min) fillers with customizable contact parts and overload protection—popular in pharma packaging.

9. Royal Pack Industries

Headquarters: Mumbai, India

Overview: Offering GMP-compliant RP series tube fillers, Royal Pack features anti-leak nozzles, 304L stainless construction and adjustable fill rates for gels, pastes and toothpastes.

10. PPS A/S

Headquarters: Birkeroed, Denmark

Overview: PPS’s machines like the IMA C735 incorporate robotic tube loading, quick-release metering pumps, and fully automated batch coding—a strong choice for large multinational lines.

11. Syntegon Packaging Technology

Headquarters: Waiblingen, Germany

Overview: Formerly Bosch Packaging Technology, Syntegon’s tube filling solutions integrate CIP, multi-component dosing and ultrasonic sealing—trusted by major toothpaste brands worldwide.

Choosing the Right Tube Filling Machine

When evaluating suppliers, consider:

Throughput vs. Budget: Semi-automatic units cost less but cap at 200–400 tubes/min; fully automatic lines exceed 1,000 tubes/min.

Product Compatibility: Ensure the machine handles your viscosity—from clear gels to heavy creams—and is compatible with your plastic tube materials (PE, PP, laminate).

Sealing Technology: Hot-air, ultrasonic or crimp-fold—select based on your product’s heat-sensitivity and barrier requirements.

Hygiene & Compliance: Look for 304/316 stainless steel, FDA-approved seals and easy-access panels for routine cleaning.

Service & Support: Global companies may offer faster on-site service; regional firms can be more cost-effective for spare parts.

Conclusion and Next Steps

With the global tube filling machine market projected to grow alongside rising demand for toothpaste, cosmetics, and functional pastes, choosing the right equipment partner is essential. From Poland’s NEWECO to Denmark’s PPS, and China’s Grand Tube Filling Machine at #3, each manufacturer brings unique strengths in automation, hygiene and versatility.

Ready to streamline your production? Visit the manufacturers’ websites above, request demos, and compare technical specs. For full-line automation—including mixing, filling, sealing and coding—the Grand GT-300 offers an ideal balance of precision, efficiency and ROI.