What is an excellent blister packaging line manufacturer?

4 Types of Veterinary Medicine Formulations: Which One Suits Your Needs?

The Evolution of Traditional Chinese Medicine in Pharmaceutical Packaging

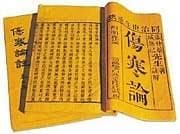

The legacy of Traditional Chinese Medicine (TCM) is deeply embedded in the history of healthcare and continues to influence modern pharmaceutical practices. Groundbreaking texts such as Zhang Zhongjing’s Shang Han Lun (Treatise on Febrile Diseases and Miscellaneous Diseases) and Li Shizhen’s Compendium of Materia Medica have not only shaped centuries of medical thought but have also provided the foundational principles that guide today’s pharmaceutical formulation and packaging.

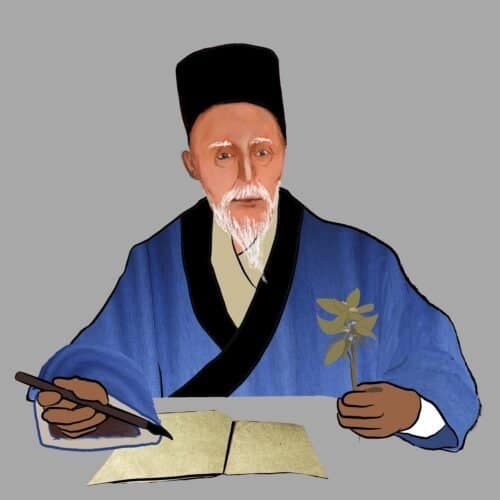

Zhang Zhongjing-Traditional Chinese Medicine Medical Saint,Source: Baidu

This article explores how ancient TCM wisdom has merged with modern technology—exemplified by state-of-the-art equipment like the Capsule Filling Machine, Tablet Press Machine, and Solid Preparation Granulation Line—to revolutionize the pharmaceutical packaging industry in China and beyond.

The Historical Foundations of TCM

For over two millennia, TCM has been at the forefront of healthcare in China. Zhang Zhongjing’s Shang Han Lun is one of the earliest systematic treatises, providing detailed diagnostic methods and therapeutic prescriptions for febrile diseases. This work introduced the concept of syndrome differentiation, a practice that remains central to TCM today.

Source: Wikipedia,Treatise on Febrile Diseases-Shang Han Lun

Similarly, Li Shizhen’s Compendium of Materia Medica compiled extensive knowledge of herbs, their properties, and their therapeutic applications. Together, these texts have established a comprehensive framework that blends observational insights with empirical evidence, paving the way for modern herbal medicine research and development.

Li is the author of a 27-year work, the Compendium of Materia Medica (Chinese: 本草綱目).

Historical documents reveal that the systematic approach to herbal formulations in these texts was revolutionary. They meticulously recorded the efficacy of various natural ingredients, allowing future generations to refine and standardize these prescriptions. Such a detailed account of herbal properties is a testament to the early integration of clinical practice and scientific observation in TCM.

Modern Pharmaceutical Packaging: A Fusion of Tradition and Technology

In today’s pharmaceutical industry, precision and consistency are paramount. As consumer demand for quality herbal products increases, manufacturers are increasingly turning to advanced machinery to meet rigorous standards. China Pharmaceutical Packaging has evolved to embrace innovations that ensure the safety, efficacy, and consistency of herbal medicines derived from TCM.

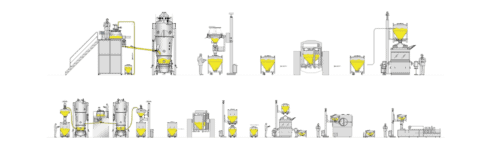

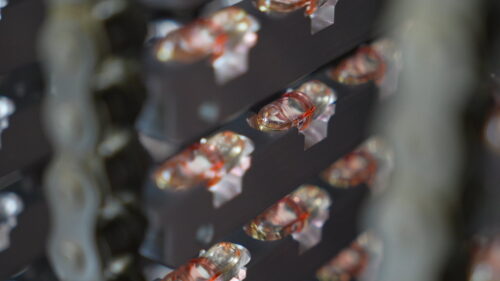

Modern equipment, such as the Capsule Filling Machine, Tablet Press Machine, and Solid Preparation Granulation Line, has become integral to pharmaceutical production. These machines not only enhance productivity but also help in standardizing formulations that were once based solely on empirical knowledge. The Capsule Filling Machine, for example, enables precise dosing and encapsulation of herbal extracts, ensuring that each capsule meets strict quality control standards. This technological advancement is particularly important in maintaining the therapeutic integrity of TCM formulations while scaling production for a global market.

The Tablet Press Machine plays a critical role in converting powdered herbal extracts into compact, consistent tablets. Through advanced compression technology, this machine ensures that each tablet contains the correct proportion of active ingredients, which is essential for the reproducibility of herbal formulations. Meanwhile, the Solid Preparation Granulation Line is designed to process raw herbal materials into granules, facilitating uniform mixing and subsequent processing. This step is crucial for ensuring that the final product retains the efficacy of its natural ingredients while meeting modern quality standards.

Integrating TCM Principles with Modern Production Techniques

The integration of ancient herbal wisdom with modern production technology is a fascinating evolution. The methods described in Shang Han Lun and Compendium of Materia Medica were based on careful observation and trial, whereas today’s pharmaceutical packaging leverages precise engineering and automation. This synergy creates a production environment where tradition meets innovation.

Standardization of Herbal Formulations

One of the most significant challenges in modernizing TCM is the standardization of herbal formulations. Historically, herbal prescriptions varied based on the practitioner’s interpretation and the regional availability of ingredients. Modern pharmaceutical packaging has overcome this challenge by using automated machinery to produce consistent dosages and formulations.

The Solid Preparation Granulation Line is at the heart of this process. It transforms raw herbal extracts into granulated forms, which are then uniformly processed, ensuring that every batch of medicine maintains the same therapeutic profile. This method not only preserves the efficacy of traditional formulations but also enhances safety and reliability for consumers.

Efficiency and Quality Control in Production

The transformation from manual herbal preparation to automated processes has led to significant improvements in efficiency and quality control. The Capsule Filling Machine and Tablet Press Machine enable manufacturers to produce large quantities of herbal medicines with minimal human error. These machines are equipped with sensors and advanced control systems that continuously monitor the production process. This real-time monitoring ensures that any deviation from the set parameters is immediately corrected, thereby maintaining high quality standards throughout the production cycle.

Moreover, automated systems facilitate rigorous quality control testing, including weight variation, content uniformity, and dissolution testing. By integrating these quality assurance measures into the production line, manufacturers can confidently deliver products that meet international regulatory standards. This level of precision and reliability is critical for expanding the global reach of TCM products and reinforces the reputation of China Pharmaceutical Packaging as a leader in the field.

Enhancing Product Stability and Shelf Life

Pharmaceutical packaging plays a pivotal role in protecting the integrity of herbal medicines. Modern packaging solutions are designed to shield sensitive compounds from environmental factors such as light, moisture, and air. This is particularly important for TCM products, where the natural active ingredients can degrade if exposed to unfavorable conditions. Advanced packaging materials and technologies help in maintaining product stability, thereby extending the shelf life of herbal formulations. This aspect of modern packaging technology ensures that the therapeutic benefits of TCM are preserved from production to consumption.

The Impact on Global Pharmaceutical Markets

The evolution of TCM through modern pharmaceutical packaging technology has had a profound impact on the global market. Consumers worldwide are increasingly seeking natural and holistic remedies, driving demand for high-quality herbal products. The combination of ancient TCM principles with advanced machinery has enabled manufacturers to scale production without compromising the integrity of traditional formulations.

International regulatory bodies now recognize the value of TCM products when they are produced under stringent quality control measures. The adoption of technologies like the Tablet Press Machine and Solid Preparation Granulation Line has helped bridge the gap between traditional herbal medicine and modern pharmaceutical standards. This has opened up new markets for TCM products, boosting exports and enhancing China’s reputation as a hub for innovative pharmaceutical packaging solutions.

Moreover, the collaboration between researchers, engineers, and TCM practitioners has spurred further innovation in both product development and packaging technology. Ongoing research into the molecular mechanisms of herbal compounds is paving the way for more targeted therapies, while advanced machinery continues to improve the precision and efficiency of production processes.

Case Study: Transforming an Ancient Formula into a Modern Pharmaceutical Product

Consider a traditional herbal formula used for boosting immunity—a recipe that has been refined over centuries based on the principles laid out in Compendium of Materia Medica. In its traditional form, the formula was prepared manually, with herbs being carefully measured, boiled, and mixed. However, modern pharmaceutical packaging has transformed this process.

- Raw Material Processing: Using the Solid Preparation Granulation Line, the herbal extracts are processed into a fine granulated form. This step ensures uniformity and enhances the solubility of the active compounds.

- Dosage Formulation: The granulated material is then fed into a Capsule Filling Machine, where it is accurately dosed into capsules. This process guarantees that each capsule contains the precise amount of active ingredients required for therapeutic efficacy.

- Compression and Tablet Formation: Alternatively, the granulated material can be compressed using a Tablet Press Machine. This machine ensures that each tablet is of consistent weight and hardness, making it easier for consumers to manage their dosage.

- Packaging and Quality Assurance: Finally, the finished products are packaged using advanced pharmaceutical packaging systems that protect them from environmental degradation, ensuring a longer shelf life and maintained potency.

This streamlined process not only preserves the traditional wisdom embedded in the formula but also leverages modern technology to meet contemporary quality and regulatory standards.

The Future: Innovation at the Intersection of Tradition and Technology

As we look to the future, the integration of TCM and modern pharmaceutical packaging is poised for further innovation. Emerging technologies such as artificial intelligence, machine learning, and advanced robotics are set to enhance every stage of the production process. For example, AI-driven quality control systems could predict and prevent production anomalies, while smart packaging solutions might provide real-time tracking of product integrity throughout the supply chain.

Furthermore, the research into novel herbal compounds continues to evolve. Modern analytical techniques are enabling scientists to isolate and identify active ingredients with unprecedented precision, opening up new possibilities for drug development. This convergence of traditional herbal knowledge and cutting-edge technology promises to bring about a new era in pharmaceutical manufacturing—one that respects ancient wisdom while embracing modern efficiency and safety.

Conclusion

The journey of Traditional Chinese Medicine from ancient texts to modern pharmaceutical packaging is a testament to the enduring value of historical wisdom and its adaptability in the face of technological advancement. The pioneering work of Zhang Zhongjing and Li Shizhen has provided a robust foundation for understanding the therapeutic potential of natural ingredients. Today, with the aid of advanced machinery such as the Capsule Filling Machine, Tablet Press Machine, and Solid Preparation Granulation Line, manufacturers can transform these age-old remedies into standardized, high-quality products that meet global regulatory standards.

This synthesis of tradition and modernity not only enhances production efficiency but also ensures that the rich heritage of TCM continues to benefit modern healthcare. By integrating the meticulous practices of ancient herbal formulation with state-of-the-art pharmaceutical packaging, the industry is paving the way for innovative therapies that honor the past while embracing the future.

As consumer demand for natural and effective remedies continues to grow, the impact of this evolution will only become more significant. The future of TCM in modern pharmaceutical manufacturing is bright—driven by a commitment to quality, innovation, and the seamless integration of traditional practices with modern technology. This evolution is not only shaping the landscape of China Pharmaceutical Packaging but is also setting new standards for global pharmaceutical production, ensuring that the timeless benefits of Traditional Chinese Medicine continue to thrive in a rapidly advancing world.

References

1. Dong, J., 2013. The relationship between traditional Chinese medicine and modern medicine. Evidence‐Based Complementary and Alternative Medicine, 2013(1), p.153148.

2. Boachie, G., 2015. Packaging and its significance on the presentation of traditional herbal medicine in Ghana: Kumasi, a case study.