Top 10 Blister Packaging Machine Manufacturers In America

Thermoforming Blister Packaging Machine – Definition, Types, How It Works, and Why You Need One!

The Ultimate Guide To Rotary Tablet Press Machines

Do you ever wonder how the pills that you consume in medical bottles always look perfect in shape? They contain thousands of loose powder particles, compressed into a tablet. Rotary tablet press machines are responsible for making these pills. Read on and let’s explore more about how these machines work.

What Is A Rotary Tablet Press?

The main functionality of a rotary tablet press is to compress granular or powdered materials for creating tablets. They are quite popular in the nutraceutical and pharmaceutical industries. In other words, these machines are responsible for producing the tablets that we consume as medicine.

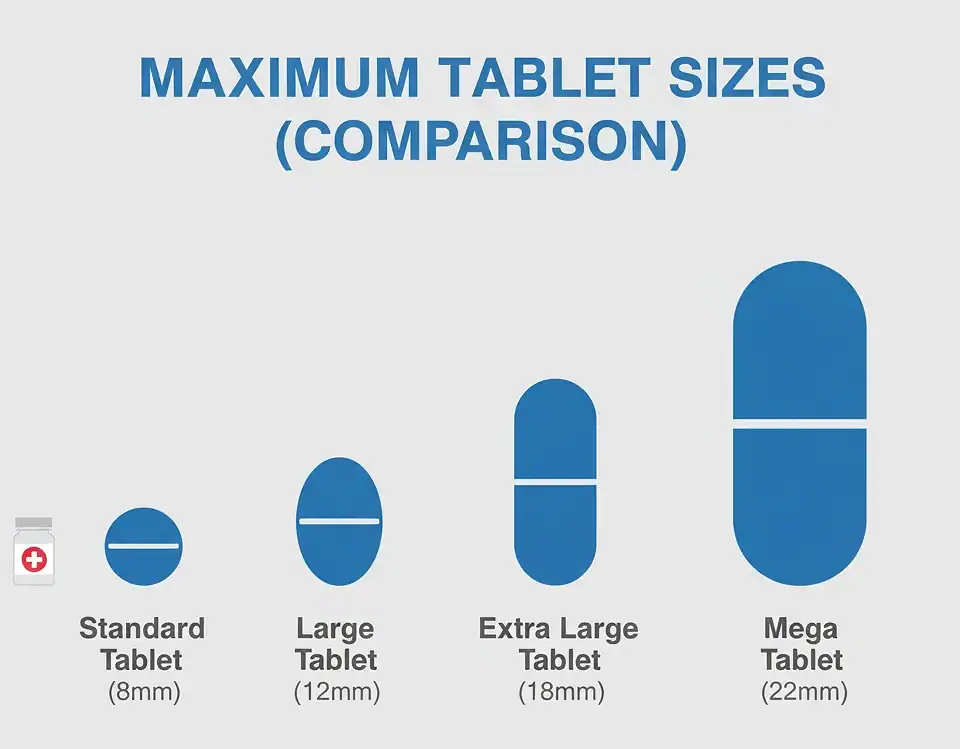

One of the main benefits of a rotary tablet press is the ability to produce tablets at a high speed. They also ensure precise control over hardness, thickness, and weight of the tablets. As a result, the end result will be perfect at all times. The latest rotary tablet press machines come with in-built quality control methods too.

What is the Working Principle of a Rotary Tablet Press Machine?

The main component of a rotary tablet press machine is the rotating turret. It is capable of holding a large number of dies³ and punches at the same time. They will compress and shape powder granules to create tablets in consistent weights and sizes. While rotating continuously, the turret will punch powder to create tablets. Here’s a detailed overview of how the process looks like.

Step 1 – Filling

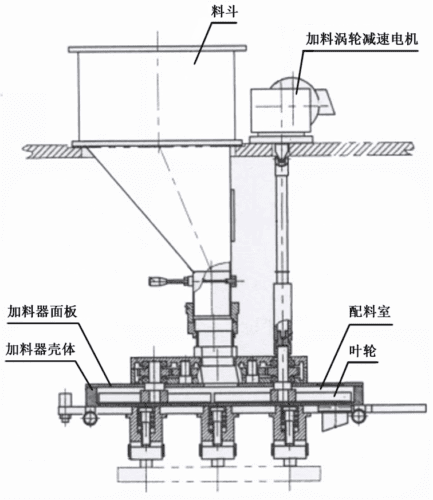

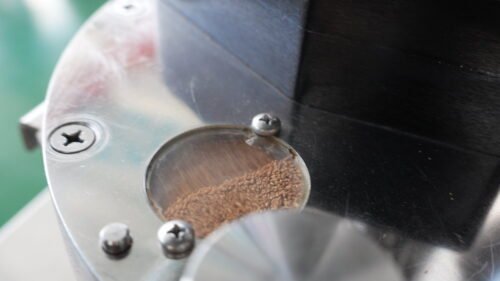

The very first step is to fill the tablet press machine with granular or powdered particles. From the loading hopper, this material will flow to the frame. Frame is nothing but a force-feeding device. It is capable of distributing the materials evenly into cavities.

Step 2 – Metering

This stage will ensure that there is current amount of dosing material available within the cavities. It will ensure uniform composition and weight of tablets at the end of the day.

Step 3 – Compression

Compression happens in two different steps. The first step out of them is pre-compression. This is where the upper part will apply moderate pressure to the material inside die cavity. It will create a slug. The slug will function as the foundation behind main compression process. It will remove the possibility of having air pockets or voids within the tablet.

The main compression process swill shape the tablet into its final form. It will also ensure proper density, thickness, and hardness of the tablet. You will be able to adjust them according to the preferred characteristics of the tablet.

Step 4 – Ejection

The final step is to eject the tablets. They will get into a tray in a gentle manner with the help of lubricants. As a result, you can make sure that the tablets will not encounter any form of damage. The advanced tablet pressing machines are capable of quality control as well.

What Are The Core Components Of Rotary Tablet Press Machines?

Let’s take a look at the main components you can find inside a rotary tablet press machine:

- Hopper¹ – You will be injecting all raw materials into the rotary tablet press machine through hopper. It usually comes with a stainless steel construction.

- Feeder system – This is the part where fine materials will enter into the die system. It also comes in a stainless steel construction.

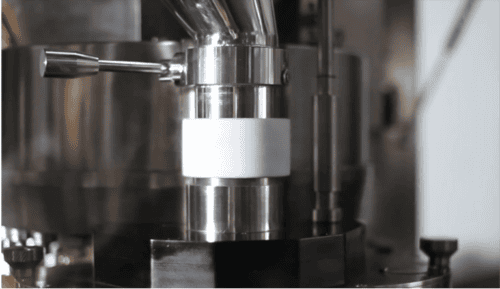

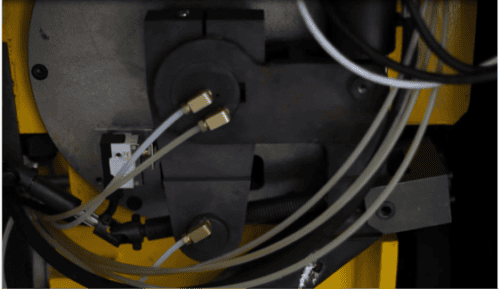

- Press punches – The punch will move within the die, while squeezing fine material to create tablets.

- Die system – The die system will define the final size and shape of tablets that you are producing.

- Tablet press turret – This is the part that is responsible for housing the die system. It will ensure that the dies and punches align with the compression process.

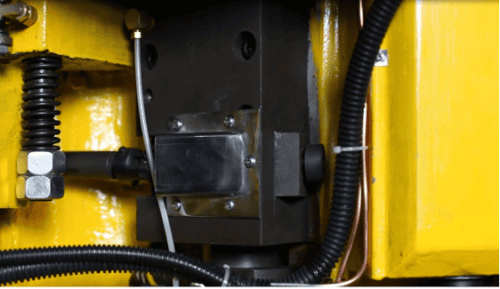

- Cam trucks – This ensures a seamless process with tablet producing.

How to Clean Rotary Tablet Press Machine?

While using a rotary tablet press machine, you are responsible for regular cleaning of it as well. It will help you with maintaining overall hygiene. To begin cleaning, you need to unplug the machine from power. Then you need to remove all the granules. With the help of a 95% ethanol solution and a paper towel, you can clean all parts of the machine.

To access the upper punches, you may disassemble it from the door on right hand side. Then you can unfasten all die locks with an alley key. By spinning the shaft, you may clean all the access ports. Optionally, you can proceed to clean the die boreholes as well.

What Is Difference Between Single Punch Tablet Press And Rotary Tablet Press?

In a single punch tablet press, you can find only one tooling station. It will have a die along with upper and lower punches. You will be able to operate this type of a tablet press machine manually or by power. However, it will not be possible for you to produce tablets from different materials. For that, you will need to use a rotary tablet press. A rotary tablet press even allows you to adjust the filling depth, rotation speed, and thickness of the tablet.

What is Rotary Tablet Press Machine Used For?

A variety of industries use rotary tablet press machines. However, pharmaceutical industry holds a prominent place out of them. Pharmaceutical companies use these machines to produce vitamins and tablets. Some other industries that use rotary tablet press machines include herbal, confectionary, and cosmetics.

What is Multi-station Tablet Press Dies and Punches²?

This refers to a tablet press station that comes along with more than one punches and dies. By using a multi-station tablet press machine, it will be possible for you to manufacture hundreds of tablets at a time. Hence, manufacturing plants with a high demand for their products consider going for this option.

How does Rotary Tablet Press Control Weight of counting Tablets?

Compression force is the factor that rotary tablet press machines use to control weight of counting tablets. The gap that exist in between rollers exerting pressure will ensure uniform weight distribution within the tablet. On the other hand, the manufacturers can pre-determine the pressure, thickness, and hardness of the tablet.

What Determines the Production Capacity of Rotary Tablet Press?

The key components that exist within the rotary tablet press machine will determine its overall production capacity. They include lower punches, upper punches, and the die. Moreover, rotation speed can also create a significant impact on the overall production capacity.

What Are The Supporting Facilities For The Optional Tablet Press?

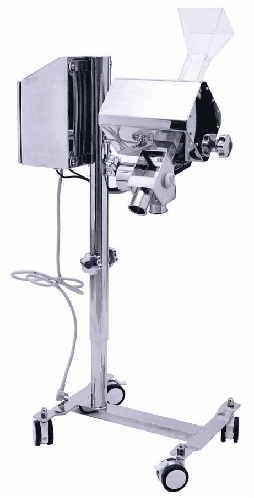

Apart from the core components, there are many supporting equipment that you use along with a machine. They include:

- High mixer machines for mixing the ingredients homogeneously

- Fluid bed granulation machines to produce formulation of tablets

- Weight checker machines to ensure the overall weight of tablets

- Metal detectors to ensure that there aren’t any fragments within the tablets

- Table coaters to coat the tablets

- Fluid bed dryers to dry wet granules

- Conical mill for sizing the granules before forming tablets

How do you Troubleshoot Rotating Pill Press Machine?

While operating a rotary tablet press machine, you can encounter errors. Here are some steps that you can follow to troubleshoot those errors.

Wear of Pressing Wheel

It will happen due to not having sufficient lubrication on the wheel. Hence, make sure to lubricate the pressing wheel at all times.

Wear of Upper Track

This also happens due to lubrication issues. Before operating the rotary tablet press machine, you need to lubricate and air compress it.

Dirt Accumulation

You need to use an air compressor and remove dirt accumulated within the machine regularly. Otherwise, it can result in excessive wear out of components. Moreover, it will also slow down the overall production process.

Inconsistent weight of tablets

This happens mainly due to the excessive wear and tear of feeder. You will need to adjust or replace the feeder to overcome this issue.

Application of Rotary Tablet Press Machine

Pharmaceutical industry: used to compress drug powder into tablets to ensure accurate drug dosage and uniform shape. Commonly used in the production of medicines, nutritional supplements, vitamins, etc.

Food industry: tablet presses are used to produce nutritional tablets, chewing gum, instant foods, etc.

Chemical industry: used to press chemical raw materials such as fertilizers, detergents and other solid tablets.

Health care products industry: used to press various health tablets, nutritional supplement tablets, etc.

Laboratories and research institutions: small-scale production and experimental tablets.

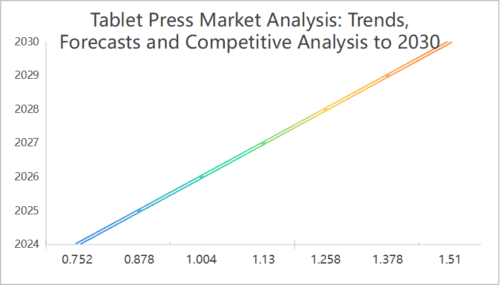

Tablet Press Market Trend Analysis in 2030

The future of the global tablet press machine market looks promising with opportunities in the pharmaceutical and food markets. The global tablet press machine market is expected to reach an estimated $1.51 billion by 2030 with a CAGR of 9.5% from 2024 to 2030. The major drivers for this market are rising demand for pharmaceutical and nutraceutical products across the globe and increasing need for efficient and advanced tablet manufacturing processes.

Data Source:https://cn.gii.tw/report/luci1560322-tablet-press-machine-market-report-trends-forecast.html

Tips For Buying Rotary Tablet Press Machine

When purchasing a rotary tablet press machine, there are some tips to keep in mind. Let’s explore them in detail.

- Consider the production capacity you need - tablet presses range from low volume to high volume capabilities

- Pay attention to compression force - more force allows you to compress more ingredients into tablets

- Look for quick changeover dies - this allows faster transition between different tablet sizes/shapes

- Evaluate controls and automation features - advanced models allow more precision and customization

- Seek GMP compliance if making pharmaceutical tablets - GMP-compliant presses meet stringent health/safety standards

- Examine punch and die material - hardened steel allows longer component lifetimes

- Assess dedusting features - integrated vacuum removal of powder reduces contamination

- Check range of usable ingredients/powders - some models handle delicate ingredients better

- Consider extra features like in-process monitoring, tablet testing ports, etc.

- Choose vendor reputation and reliability - look for guarantees, service, and support

- Compare pricing across brands and models to suit your budget

- See a demo model in action before purchase to assess noise/vibrations/ease-of-use

Final Words

Now you have a clear idea of how a rotary tablet press machine works. If you are planning to get a one, make sure to do it from a reliable vendor that you can always rely on. Then you can experience all benefits that come along with it.

Reference

1.Ketterhagen W R. Simulation of powder flow in a lab-scale tablet press feed frame: effects of design and operating parameters on measures of tablet quality[J]. Powder Technology, 2015, 275: 361-374.https://www.sciencedirect.com/science/article/abs/pii/S003259101500100X

2.Murray, F. J. (1996). Tablet Press Automation: A Modular Approach to Fully Integrated Production. Drug Development and Industrial Pharmacy, 22(1), 35–43. https://doi.org/10.3109/03639049609043870

3.Mendez R, Muzzio F, Velazquez C. Study of the effects of feed frames on powder blend properties during the filling of tablet press dies[J]. Powder Technology, 2010, 200(3): 105-116.https://www.sciencedirect.com/science/article/abs/pii/S0032591010000847