Blister Line Working Principle, and Application Packaging

Mixer Emulsifier: Introduction, Working Principle, Types, and Application Products

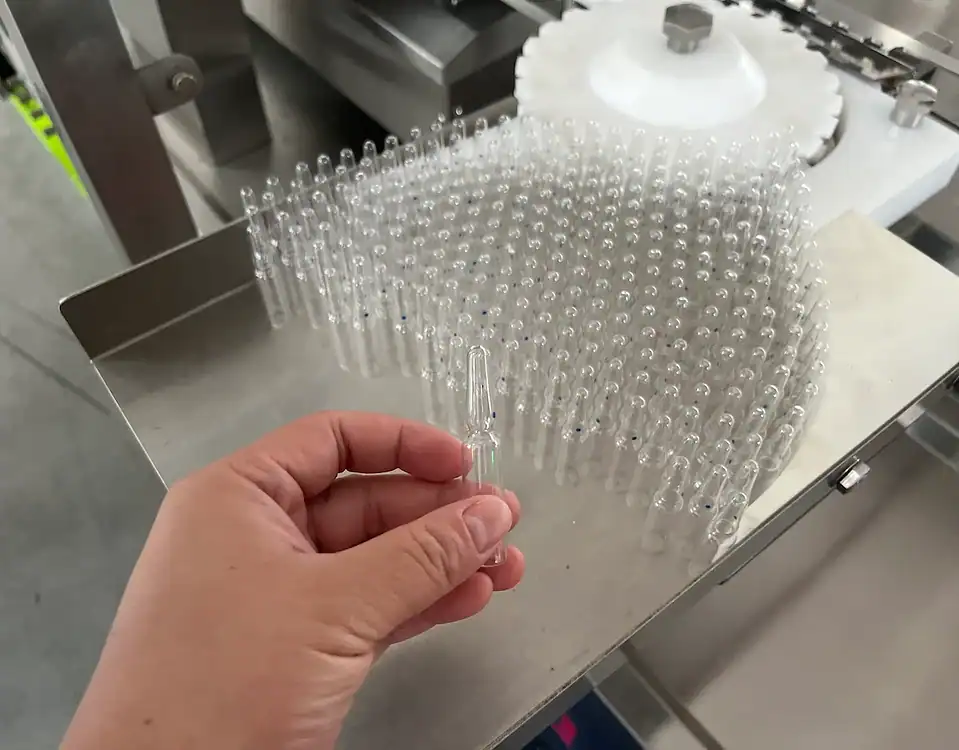

Vial Filling Machine: Introduction to Types, Working Principles, and Applications

When you think of medical equipment, you likely think of the things you see during every doctor’s visit. Everyone knows what gloves, masks, and stethoscopes are. However, behind the scenes, there’s one tool that has a massive impact on the entire industry. It’s also important for many other industries.

Vial filling machines are important, but most people don’t know about them unless they work with them. Today, we’re going to go over what a vial filling machine is, what some types of vial filling machines are, and what they’re used for.

Let’s get started.

What is a Vial Filling Machine?

A vial filling machine is exactly what it sounds like. It’s a machine that fills a wide variety of vials with exact measurements.

This is what makes it such an important part of the medical industry and similar industries. With most medications and medical liquids, exact measurements are required. If those measurements are wrong, there can be serious problems.

A vial filling machine allows manufacturers and other users to determine exactly how much of a liquid they need in the bottle, and then the machine takes care of all the precise work automatically.

What is the Working Principle of a Vial Filling Machine?

There are two types of vial filling machines we’ll discuss soon. Each has its own working principle.

The most common vial filling machines use the working principle of gravity. The same force that is used to hold you to the ground pulls the liquid out of the filling machine. How much enters the bottle is limited by the machine.

The second type is a little more complicated, and it’s used when bottles can’t have air in them.

Instead of gravity pulling the liquid out, a vacuum is made. The machine measures the volume of the liquid needed, and then it puts it in that vacuum. Sometimes, multiple liquids are added to make a solution.

Vial Filling Machine Types

While there are lots of brands and models, all vial filling machines are one of two types.

The first uses gravity and pressure to fill vials.

Pressure-based filling machines use stoppers and caps to limit the liquid. This prevents too much or too little from going in the vial. Then gravity pulls it into the vial without any foaming, excess dripping, or other problems. The machine also uses a small amount of pressure, too.

Then, there are vacuum-based vial filling machines. These measure by volume and create a vacuum before filling.

A vacuum is created in the vial filling machine and the vial. The volume of the liquid being dispensed is measured, and then it’s allowed into the bottle. Since there is no air, the liquid is more stable over long periods. It’s also important when mixing solutions that create a reaction.

Vial Filling Machine Applications

Vile filling machines have a lot of different applications. While many people don’t see them in action, they are a big part of several major industries.

They’re used in practically any application that requires precise amounts of liquid or granular materials to be placed into small plastic or glass vials.

As we’ve talked about so far, the medical industry is one of the largest users of vial filling machines.

Every time you go to the doctor for a flu shot, an injectable medicine, or even many ingestible medicines, those vials have been filled with a vial filling machine.

The biotech industry also uses vial filling machines frequently. The biotech industry uses vial filling machines to package life-saving medicines, optional medications for things such as weight loss, and similar products. This also greatly helps the healthcare industry,

However, applications for vial filling machines go far beyond that.

Another user of these machines is the food production industry.

There are many different food products that are stored in glass or plastic vials. They don’t have to be measured precisely for safety reasons, but it’s still important. Manufacturers want to avoid overfilling or underfilling their packaging. Too much product can cost the company money. If a product does not have enough, it can leave customers unsatisfied.

You will see products such as these with food-grade dyes, liquid food additives, some higher-quality spices and seasonings, energy supplements, dietary supplements, and similar products. This also highlights how not all vial filling machines are solely meant for liquids. They can be used for granular ingredients, too. Such as spices and seasonings in the food industry.

Finally, the pharmaceutical industry uses vial filling machines on a daily basis. Usually, they are used to mix medicines on-site from raw ingredients. However, they’re also used by the manufacturers to fill pre-made medication products.

You’ll find vial filling machines in many other industries, too. They can be great for mass-producing a lot of products. If a company needs very precise measurements for its products, and it wants to mass-produce those products effectively, they will likely use a vial filling machine.

What to Take Away from This

Vial dispensers are a lot more common than you likely think. There are 3 main reasons they’re so common.

First, they make it very easy to fill vials with exact measurements. In the medical field and biotech field, this is very important for patient safety. Too much or too little of any ingredient can have serious consequences. In the food industry and similar areas, it’s useful financially. It ensures that product isn’t wasted and customers get what they pay for.

Then, it’s also a lot more reliable. A machine can repeat the same task perfectly thousands of times. A team of people can’t beat the consistency of a vial filling machine.

Finally, the efficiency is unbeatable. One vial filling machine can fill hundreds of vials in the time it would take a human to do just a small batch.

All of these core benefits make vial filling machines crucial. They greatly boost the quality of products in a variety of industries, and they do it faster than traditional methods.