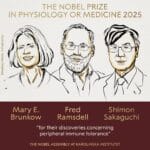

Packaging mechanical structure similar to the 2025 Nobel Prize in Medicine!

How adaptable is the Cartoning Machine?

What are cosmetics made of? Homogenizer can do it!

Introduction

How are products like ointments, creams, and toothpastes made to have a uniform, fine texture? Understanding emulsifiers makes everything simple.

Let's first understand the basic workings of an emulsifier. I've included an English diagram below. The process can be broken down into three main stages: preparation of the water and oil phases, the main emulsification process, and the final cooling and discharge stage.

The following table shows:

| Step | Location | Process / Action | Details / Key Parameters |

|---|---|---|---|

| 1 | Water Pot | Phase Preparation | Feeding of water & raw materials. Heating, blending, and dissolving. |

| 2 | Oil Pot | Phase Preparation | Weighing of raw materials. Heating, blending, and dissolving. |

| 3 | Emulsifying Pot | Initial Preparation | Preheating the main pot. |

| 4 | Emulsifying Pot | Feeding Water Phase | Transfer from Water Pot via Vacuum suction. |

| 5 | Emulsifying Pot | Pre-Blending | Blending at Blender speed variation 1. |

| 6 | Emulsifying Pot | Feeding Oil Phase | Transfer from Oil Pot via Vacuum drawing after temperature confirmation. |

| 7 | Emulsifying Pot | Emulsifying | Blending at speed variation 2 & 3 under vacuum. |

| 8 | Emulsifying Pot | Cooling & Finishing | Cooling starts. Add Essence. Blending at speed variation 4 & 5. |

| 9 | Emulsifying Pot | Final Confirmation | Cooling is finished after final temperature confirmation. |

| 10 | Emulsifying Pot | Discharging | The finished product is discharged from the pot. |