What Materials Are Used in Medical Blister Packaging? | Grandpack

Why Are Pills in Blister Packs? A Guide to Shelf Life & Safety

What Is a Shrink Wrap Machine?

Introduction

The Definitive Guide to Heat Shrink, Stretch Wrap, and 3D Overwrapping

If you are researching packaging, you might feel confused. You type "wrapping machine" into a search engine and get a flood of contradictory results. Some machines wind film around a pallet. Others create a perfect, crisp fold on a perfume box. And others shrink a plastic "skin" around a product.

Here is the secret: "wrapping machine" is a generic term for several different technologies. 1

The right machine for you depends on your purpose. Are you wrapping for:

- Retail Presentation? (A high-gloss, clean look)

- Transit Security? (Stabilizing a pallet for shipping)

- Product Protection? (A tamper-evident, hygienic seal)

This guide will demystify these technologies. We will focus primarily on heat shrink wrapping, but we will also define its two common alternatives: 3D overwrapping and stretch (winding) wrapping.

Wrapping Technology at a Glance

This table breaks down the three technologies you are likely confusing.

Technology | Core Principle | Primary Material | Primary Application |

Heat Shrink Wrap | Heat is applied to a polymer film, causing it to shrink and conform to the product. | Polyolefin (POF), Polyethylene (PE) | Retail products, food packaging, bundling items, tamper-evident seals. |

Stretch Wrap | Film is mechanically stretched (no heat). Tension and "film memory" hold the load together. | Linear Low-Density Polyethylene (LLDPE) | Securing boxes or products on a pallet for shipping and logistics. |

3D (Cellophane) Overwrap | Film is folded like a gift (often called "tuck and fold"). Small heat-seals hold the folds in place. | Biaxially Oriented Polypropylene (BOPP), Cellophane | Luxury items. Used for the "perfume box" wrap on square or cuboid items. |

The Main Event: What Is a Heat Shrink Wrap Machine?

This is the most common and versatile type of "wrapping machine." It is the primary solution for packaging individual products for sale.

The Definition: A Protective Second Skin

A shrink wrap machine is a device that encloses a product in a transparent polymer plastic film. After the product is sealed inside the film, the machine applies heat. This heat causes the film to shrink tightly over the product, creating a protective "second skin".2

The result is a clean, attractive, and professional package. This process secures the product and, most importantly, protects it from dirt, moisture, and tampering.

The Two-Step Principle: How It Really Works

Many people think you just "blast" the product with heat. The real process is more precise and involves two distinct steps: sealing and shrinking.

Step 1: Sealing (Sealing Shrink Wrap)

Before any shrinking happens, the machine must first create a "bag" of film around the product. This is the sealing shrink wrap process.19 The product is placed in a sheet of film, and a heated sealing bar or wire presses down. This bar melts the film, creating a seal and cutting off the excess material at the same time. The product is now loosely enclosed in a film bag.

Step 2: Shrinking (The Heat Tunnel)

The sealed product then moves (usually on a conveyor) into a heat tunnel.21 This component is far more than a simple oven. It is a "smart thermodynamic environment".

Inside the tunnel, a "heater bank" generates precise heat, while fans create recirculating air. This controlled, moving hot air activates the "memory" of the film, causing it to contract uniformly around every curve and angle of the product. This precision is critical. Poor temperature control or bad airflow will result in wrinkles, burn-through, or an uneven finish, compromising the quality of the package.

The Core Components: The Sealer and The Tunnel

Every shrink wrap system has two main parts that execute the two steps above.

- The Sealer (or Sealing Bar): This is the part that cuts and seals the film bag. It can be a simple hand-operated I-Bar or L-Bar (which we will cover in Section 3) or a fully automated sealing jaw.

- The Heat Tunnel: This is the chamber where the magic happens. It contains the heating elements, conveyor belt, and control panel. The control panel is vital, as it allows the operator to fine-tune the two most important variables: the air temperature and the conveyor belt speed.

The Business Benefits: Why Invest in Shrink Wrap?

Shrink wrapping is popular for a reason. It offers a powerful combination of benefits for any business.

- Protection: It forms a durable barrier against dust, moisture, and dirt, keeping the product in pristine condition from the factory to the customer.

- Tamper-Evidence: This is a key advantage. A broken shrink seal is an immediate, visible sign that a product has been opened. This builds consumer confidence and is critical for plastic wrap machine for food packaging, pharmaceuticals, and software.

- Presentation: The high-gloss, transparent film showcases the product, making it look professional and "retail-ready".

- Bundling (Multi-Packs): The machine can wrap multiple items together, creating convenient multi-packs.2 Think of a "buy one, get one free" promotion or a 6-pack of soap.

- Cost-Effectiveness: Shrink film is lightweight, which reduces shipping costs. It also uses less material and takes up less warehouse space than traditional cardboard boxes.

The Other Half of the System: Choosing Your Film

The machine and the film are a single, co-dependent system. You cannot choose one without considering the other. The type of film you use dictates the machine's settings (especially temperature) and its application.

- POF (Polyolefin): This is the modern, premium standard. It is highly durable, has excellent clarity, and is FDA-approved for direct food contact. This is the film you see on most retail products.

- PE (Polyethylene): This is the industrial-grade, heavy-duty film. It is thicker, stronger, and more puncture-resistant, but it has lower clarity (it can be cloudy). PE is used for heavy jobs, like bundling cases of beverages 31 or industrial shrink wrap equipment for boats.

- PVC (Polyvinyl Chloride): This is an older film technology. While it has good clarity, it can become brittle in cold temperatures and releases small amounts of toxic chemicals during sealing and shrinking. Its use has declined significantly.

Sizing Your Solution: From Manual Heat Guns to Fully-Automatic Lines

Shrink wrap machines are not one-size-fits-all. They range from simple tabletop tools for a home business to massive, high-speed lines for a factory.

Manual Systems (1-5 packages/minute)

- Who it's for: Startups, small e-commerce sellers, artisan shops, and gift basket makers.

- The Equipment: This is not a single machine but a "kit" of three separate tools.

- Shrink Wrap Dispenser: A simple stand that holds a roll of centerfold film.

- Sealer: A manual I-Bar or L-Bar impulse sealer. The operator places the product inside the film, then presses the bar down to make the seal and cut the film.

- Heat Source: A handheld shrink wrap machine heat... gun.2 The operator manually aims the gun and applies heat to shrink the film.

Semi-Automatic Systems (10-20 packages/minute)

- Who it's for: Medium-sized businesses that have outgrown a heat gun and need more consistency and speed.

- The Equipment: The operator still manually loads the product, but the machine automates the sealing and shrinking. This often takes two forms:

- Chamber Machines: An all-in-one solution. The operator places the product inside a chamber. A single hood descends, first sealing the film and then filling the chamber with hot air to shrink it.

- L-Bar Sealer + Tunnel: The most common setup. The operator uses an L-Bar sealer, then places the sealed package onto a small conveyor belt, which automatically carries it through a separate heat tunnel.

Fully-Automatic Systems (20-100+ packages/minute)

- Who it's for: Large-scale manufacturing, high-volume fulfillment centers, and any operation where packaging is a bottleneck.

- The Equipment: These are fully integrated systems. Conveyors feed products into the machine, which automatically senses, wraps, seals, and shrinks them without human intervention.

- The Sealer Divide: In the automatic world, there is a critical choice between two sealer types:

- Automatic L-Bar Sealers: These are workhorses for uniform packages at low to moderate speeds. Their "L" shape seals the front and side of one package at the same time. However, their fixed-size bar can be a limitation.

- Automatic Side Sealers: These are built for high speed. They use a continuous, heated wheel to seal one side of the package and a single cross-sealing bar for the front and back. This design can wrap products of any length and run much faster.

The Evolution of Sealing: The Grand Heat Shrink Machine

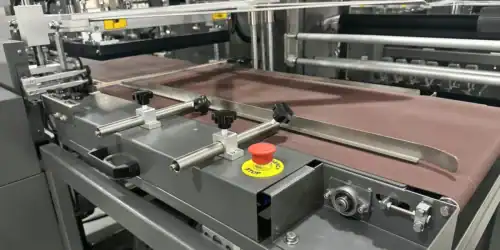

For decades, operators had to choose between the L-Bar's simple seal and the side-sealer's speed. As the image and data from Grand show, modern engineering is solving this.

Traditional L-bar designs, for example, "often compromise between speed and stability". To go fast, the large metal L-bar must slam up and down, which causes vibration, wear, and potential seal failures.

The Grand Heat Shrink Machine reimagines this process. It features a revolutionary "Vertical Sealing System".Instead of a heavy, dropping bar, this system appears to be a more precise, vertical sealing mechanism.

It is designed to apply "uniform pressure and exact heat" with "calculated poise and precision".The result is a seal that is "nearly invisible yet impossibly strong," creating a truly "flawless seal, every time".This design is quieter 50, more stable, and more reliable at high speeds.

This level of precision is not just about the mechanical design. It is also about the components running it. The real cost of any automatic machine is not its purchase price; it is the cost of downtime. As Grand notes, "any pause on the production line is a cost".

To combat this, their system is "Engineered for Endurance". This is achieved by building the machine with "world-class electrical architecture".Specifically, it features industry-leading components:

- Omron PLCs and sensors

- Schneider switches

- Panasonic VFDs (Variable Frequency Drives)

This list is a direct promise of reliability. For an operations manager, it means two things:

- Reliability: These industrial-grade components have exceptionally low failure rates, ensuring maximum uptime.24

- Serviceability: When a sensor eventually does fail, it is a standard Omron part that a local technician can source and replace.52 The line is not down for weeks waiting for a proprietary part from overseas.

This combination of an advanced vertical sealing system and world-class components creates a machine built for high performance and, more importantly, high reliability.

Alternative Technologies: 3D Overwrapping vs. Stretch Wrapping

Now, let's clearly define the other "wrapping machines" to ensure you choose the right path.

What is a 3D (Cellophane) Overwrapping Machine?

This machine is not a shrink wrapper. It is an "overwrapper".

- The Process: It takes a pre-cut sheet of clear film (like cellophane or BOPP) and wraps it around a product. It then meticulously folds the ends, just like wrapping a gift. Small heated plates then tack down the "Tuck and Folds" to create a crisp, "diamond-like" seal.

- The Result: A high-gloss, premium package. This is the classic "cigarette box" or "perfume box" wrap.

- When to use it: This machine is for "presentation-focused products" 15 where a "sense of luxury" is the primary goal.13 Its major limitation: it only works on "cubic or cuboid shapes" like boxes.

What is a Stretch (Winding) Film Wrapping Machine?

This machine is also not a shrink wrapper. It is often called a "pallet wrapper" and it uses no heat to apply the film.

- The Process: A stretch wrapper uses a special LLDPE film with high elasticity. The machine "stretches" this film, often to 200-300% of its original length, as it winds it around a load.

- The Result: The film's "polymer memory" creates a powerful "constrictive force".It constantly pulls inward, tightly binding the boxes to the pallet.

- When to use it: This machine has one job: logistics. It is used almost exclusively for securing pallet loads for transportation and shipping. It is not used for primary product packaging.

Shrink Wrap in Action: A Tour of Industrial Applications

The versatility of heat shrink technology makes it a staple in almost every industry. Here is how it is used to solve specific challenges.

Shrink Wrap Machine for Food Packaging

This is one of the largest uses for shrink wrap. When used as a wrapping machine for food, the benefits are about safety and freshness.

- Hygiene: The airtight seal 7 protects plastic wrap machine for food products from dust, moisture, and contaminants.

- Freshness: It preserves quality and extends the shelf life of baked goods, produce, and meats, which prevents spoilage.

- Tamper-Evidence: It gives consumers critical confidence that the food has not been touched or tampered with.

- The System: This application requires the use of FDA-approved, food-contact-safe films like POF. The machines themselves are often made of stainless steel to handle the hygienic washdown requirements of food plants.

Shrink Wrap Machine for Bottles: The Two Meanings

The keyword shrink wrap machine for bottles is highly ambiguous. It refers to two completely different processes. An expert must clarify this confusion.

Application 1: Shrink Sleeve Labeling (Branding)

- What it is: This process applies a 360-degree graphic label to a single bottle or can.

- The Machine: A pre-printed "sleeve" (a tube of film) is dropped over the bottle. The bottle then passes through a specialized "sleeve labeling shrink tunnel".This tunnel often uses steam instead of hot air, as steam provides more gentle, uniform heat, shrinking the label perfectly to the container's contours without damaging it.

Application 2: Shrink Bundling (Sleeve Wrapping)

- What it is: This process groups multiple bottles or cans into a multi-pack for sale (e.g., a 24-pack of water).

- The Machine: This machine is called a "sleeve wrapper".61 It wraps a "sleeve" of heavy-duty PE film around the group of bottles. The bundle then goes through a "bundling tunnel". This process often leaves two open "bulls-eye" holes on the side, which can be used as carrying handles.

Shrink Wrap Equipment for Boats and Heavy Industry

- What it is: This application is not about retail. It is about "weatherizing" and protecting high-value assets like boats, helicopters, or large industrial equipment from the elements during transport or outdoor storage.

- The Equipment: This process does not use an automatic "machine." It uses a heavy-duty, manual kit. The essential components are:

- A Propane Heat Gun: A powerful, propane-fired heat tool (like a Shrinkfast or Ripack) that produces far more heat than a small electric gun.

- Thick PE Film: Rolls of very thick (8-12 mil) Polyethylene film with UV inhibitors.

- Accessories: Woven cord strapping to create a support structure under the film, adhesive vents to allow air to circulate and prevent mold 67, and special shrink wrap tape for seams.

- The Process: The boat or object is covered with the large film, which is then secured with the strapping. The operator then uses the propane heat gun to walk around the entire object, manually shrinking the massive cover.

Conclusion: Choosing the Right Wrap for Your Product

You are now equipped to navigate the world of packaging. The confusion around "wrapping machines" is solved by asking one question: "What is my purpose?"

Here is your final decision-making guide:

- IF your goal is to secure a pallet of boxes for shipping, THEN you need a Stretch Wrapping Machine.

- IF your goal is to create a high-luxury, "tuck and fold" package for a square box, THEN you need a 3D Overwrapping Machine.

- IF your goal is to protect a product, create a tamper-evident seal, bundle items for retail, or provide a hygienic food-safe cover, THEN you need a Heat Shrink Wrap Machine.

If you determine that a heat shrink machine is your solution, your final consideration is the true cost of that machine. The sticker price of a shrink wrapper is only the beginning. The real, long-term cost is downtime.

As the Grand machine's design philosophy states, "any pause on the production line is a cost".

When you choose your machine, look beyond the initial price. Prioritize smart engineering, proven reliability, and the quality of the components. A machine that is "Engineered for Endurance" and built with world-class, non-proprietary parts will save you far more money in uptime, productivity, and "flawless seals" than a cheaper machine will save you on day one.

References

- Shrink wrap - Wikipedia.November 8, 2025