5 Industries Transformed by the Heat Shrink Wrapping Machine

Powder filling machine and production line case

A Deep Dive into the Modern Cartoning Machine

Introduction

In the fast-paced world of manufacturing, efficiency, precision, and reliability are paramount. From pharmaceuticals to food and beverage, cosmetics to consumer goods, the final step of packaging is as crucial as the product itself. This is where the cartoning machine steps in, a silent workhorse of the production line, transforming loose products into neatly packaged, shelf-ready items. But not all cartoning machines are created equal. As technology evolves, so does the sophistication of this essential piece of cartoning equipment. This comprehensive guide will take you beyond the box, exploring the intricacies of modern cartoning systems, comparing them to conventional machinery, and shedding light on what makes truly exceptional cartoner machinery, such as the Grand ZH-260, stand out.

But the true power of this technology lies in its incredible adaptability. From delicate cosmetics to heavy industrial parts, the applications are nearly limitless. In this guide, we will explore five major industries that have been transformed by the capabilities of heat shrink wrapping, highlighting how this single solution addresses a wide range of packaging challenges.

What is a Cartoning Machine and Why is it so Important?

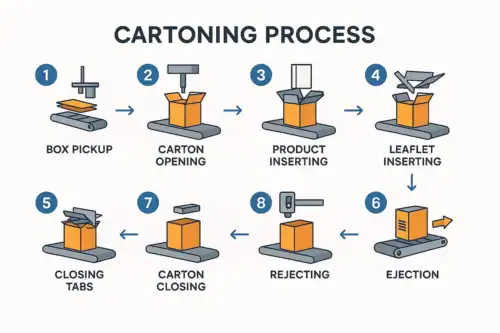

A cartoning machine, also known as a cartoner, is an automated packaging machine that erects, closes, and seals cartons. Its primary function is to take a flat, pre-glued carton blank, form it into a box, insert a product or multiple products (often along with a leaflet or booklet), and then close the carton by tucking in the flaps or applying glue.

Where is the cartoning machine manual placed

The importance of a reliable cartoning system cannot be overstated. It directly impacts:

- Production Speed and Throughput: A high-speed cartoning machine can significantly increase the number of products packaged per minute, boosting overall production capacity.

- Product Protection: A well-sealed carton protects the product from damage during transit and storage, preserving its quality and integrity.

- Brand Presentation: The carton is often the first physical interaction customers have with a product. A perfectly formed and sealed carton conveys a sense of quality and professionalism, enhancing brand image.

- Operational Efficiency: Automating the cartoning process reduces manual labor, minimizes human error, and frees up employees for more value-added tasks.

- Compliance: In industries like pharmaceuticals, cartoning machines play a critical role in ensuring compliance with strict regulations, such as GMP (Good Manufacturing Practices).

Work flow

First, the feeder dispenses blisters onto the conveyor belt

① for forward movement. When the photoelectric sensor detects a blister, the folding machine begins to fold and convey a leaflet

② Simultaneously, the carton feeding unit awaits the arrival of the blister and leaflet, performing carton feeding and opening

③ The pusher mechanism then inserts both the blister and leaflet together into the carton

④ As the machine operates, the carton-gripping conveyor chain transfers the carton sequentially t: the rear minor flap folding system

⑤ front minor flap folding system

⑥ batch number printer

⑦ front/rear carton sealing unit

⑧ and finally discharges the sealed carton via the conveyor belt

Types of Cartoning Machines: Finding the Right Fit

Cartoning machines come in various configurations to suit different products and production needs. The two primary types are:

- Horizontal Cartoning Machines: These machines are ideal for products that are best handled horizontally, such as blister packs, sachets, and tubes. The product is pushed into the open end of the carton from the side. The Grand Cartoner Machine ZH-260 is a high-speed horizontal cartoning machine.

- Vertical Cartoning Machines: In a vertical cartoner, the carton is fed in an upright position, and the product is loaded from the top. This type is suitable for "top-load" products like bottles, jars, and certain granular or powdered items.

Beyond this basic classification, cartoning machines can also be categorized by their motion:

- Intermittent Motion Cartoners: These machines operate in a start-stop cycle. The carton stops at each station (forming, loading, sealing) for the operation to be performed. They are generally slower but can be more flexible for certain applications.

- Continuous Motion Cartoners: As the name suggests, these machines perform all operations while the carton is in continuous motion. This allows for significantly higher speeds and smoother operation, making them ideal for high-volume production lines. The Grand ZH-260 is a fully automatic, continuous-motion high-speed cartoner.

Key Considerations When Choosing a Cartoning Machine

Selecting the right cartoning machine is a significant investment that can have a long-term impact on your business. Here are some key factors to consider, with insights into how a modern machine like the Grand ZH-260 excels:

1. Speed and Efficiency: The Need for High Performance

In today's competitive market, speed is of the essence. A high-speed cartoning machine can dramatically improve your production output. The Grand ZH-260, for instance, has a design maximum capacity of 120-250 cartons per minute, though the actual speed is subject to product characteristics. However, speed alone isn't enough. The machine must also be efficient and reliable at high speeds. This is where advanced engineering comes into play. The ZH-260 boasts high efficiency and high-performance production capabilities, ensuring that you get both speed and quality.

2. Flexibility and Adjustability: Adapting to Your Needs

Product lines are often diverse, with varying product sizes and packaging requirements. A flexible cardboard packaging machine that can be easily adjusted for different carton sizes is a major advantage. The Grand ZH-260 allows for product size adjustment via a simple dial-calibrated handwheel, making changeovers quick and efficient. The machine can handle a wide range of carton sizes, from a minimum of 75×50×20mm to a maximum of 160×130×50mm.

3. Reliability and Durability: Built to Last

A cartoning machine is a long-term investment, so it needs to be built to last. The quality of components plays a crucial role in the machine's reliability and lifespan. The Grand ZH-260 is constructed with a robust machine frame made from welded channel steel and square steel plates. It utilizes components from internationally renowned brands like Siemens and Omron for its main motor, PLC, frequency inverter, sensors, and pneumatic components. This commitment to quality ensures stable operation and reduces the risk of costly downtime. The main drive system is also equipped with overload protection to safeguard the machine and the operator.

4. Ease of Operation and Maintenance: Empowering Your Team

A complex machine that is difficult to operate and maintain can lead to production bottlenecks and frustration for your staff. Modern cartoning machines are designed with user-friendliness in mind. The Grand ZH-260 features a streamlined exterior design and a rear continuous-push structure that simplifies operation and maintenance. The machine's HMI (touchscreen) provides a user-friendly interface for controlling the machine and monitoring its performance. Additionally, the machine automatically displays cartoning speed, fault alarms, and production counts, providing operators with real-time information.

5. GMP Compliance: A Must for the Pharmaceutical Industry

For pharmaceutical manufacturers, adherence to Good Manufacturing Practices (GMP) is non-negotiable. The Grand ZH-260 is strictly manufactured in compliance with the pharmaceutical industry's "GMP" requirements. This means it is designed and built to meet the highest standards of hygiene, safety, and quality, making it a suitable choice for packaging pharmaceutical products.

A Closer Look at Advanced Cartoning Systems: The Grand Engineering Approach

The Grand ZH-260 is a testament to the advancements in cartoning machine technology. Let's delve into some of its innovative features that set it apart from conventional machines:

The Heart of the Machine: The Main Drive System

A smooth and reliable drive system is the backbone of any high-speed machine. The Grand ZH-260 employs a servo motor that drives through synchronous pulleys and transmission timing belts. This design offers several advantages over traditional chain and sprocket drives. It features high wear resistance, low noise, and no need for oil lubrication. This not only reduces maintenance costs but also minimizes equipment vibration during high-speed operation, extending the service life of the machine's components.

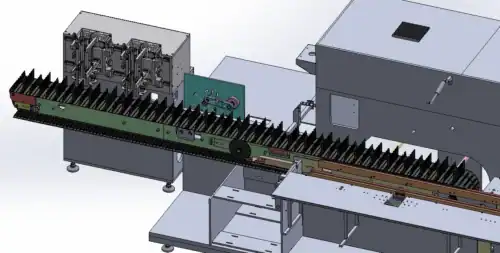

Precision in Motion: The Carton Conveying and Product Handling Systems

The accurate and gentle handling of cartons and products is critical to achieving high-quality packaging. The ZH-260's carton conveying system uses four specially designed chains that transport cartons smoothly through the machine. The position of these chains can be adjusted to accommodate different product specifications and sizes.

The product conveying chain is equally impressive, controlled by a servo motor that allows for configurable quantities of products per cycle. This feature is particularly useful for packaging multiple items in a single carton.

Intelligent Inspection: Ensuring Quality at Every Step

To minimize waste and ensure product quality, the Grand ZH-260 is equipped with a sophisticated inspection mechanism. This system uses photoelectric sensors to detect the quantity of products being fed into the machine. It can automatically detect overfilled, underfilled, or missing products and take corrective actions, such as preventing the machine from picking a leaflet or a carton. This intelligent system prevents errors before they happen, ensuring that only correctly filled packages proceed down the line.

The Gentle Push: The Advanced Pusher Mechanism

At high speeds, the process of pushing the product and leaflet into the carton needs to be precise and gentle to avoid damage. The Grand ZH-260 features a unique pusher mechanism with a dual-pusher configuration for leaflets and products. The leaflet pusher advances first, followed by the product pusher, which prevents the leaflet from causing resistance against the product. The machine's pusher operates at a low frequency even at high cartoning speeds, ensuring smooth and accurate material placement. An overload protection system with a photoelectric sensor instantly stops the machine in case of a jam, preventing damage to the pusher components.

Perfect Cartons Every Time: The Carton Suction and Opening System

The first step in the cartoning process – opening the carton – is often a source of problems in conventional machines. The Grand ZH-260 addresses this with a continuous three-head automatic carton suction and opening mechanism that ensures high-speed carton pickup and precise opening angles. A forced pre-opening mechanism prevents cartons from failing to open, while a reverse-blowing system expels paper debris to improve efficiency and prevent contamination. The system also features automatic alarms for low carton levels, preventing unnecessary stoppages.

The Finishing Touches: Batch Number Printing and Sealing

The final stages of the cartoning process are just as important as the initial ones. The Grand ZH-260 includes a batch number printing device that uses steel type to imprint codes on the cartons. The device has a fast-installation mechanism that allows for quick and easy batch number changes without the need for tools. The carton sealing system, with its modular design, ensures that cartons are perfectly sealed before they are discharged from the machine. The machine also has detection systems to verify that the flaps are correctly locked, preventing non-compliant products from reaching the next stage of the packaging line.

The Future of Cartoning: Smart, Efficient, and Sustainable

The cartoning machine has come a long way from its humble beginnings. Today's machines are sophisticated pieces of engineering that combine mechanics, optics, electronics, and pneumatics to deliver exceptional performance. As we look to the future, we can expect to see even more innovation in this field. Trends like increased automation, the use of robotics, and the integration of machine learning and AI will further enhance the capabilities of cartoning systems.

The Grand ZH-260, with its advanced features and commitment to quality, is a prime example of cartoner machinery that is ready for the future. Its innovative design, high-quality components, and user-friendly features make it an ideal choice for manufacturers looking to optimize their packaging operations and stay ahead of the competition. While the carton machine price or cardboard box making machine price is a factor, investing in a high-quality machine like the Grand ZH-260 can provide significant returns in the long run through increased efficiency, reduced downtime, and improved product quality. Choosing the right packaging machine for boxes is a critical business decision, and a machine like the ZH-260 offers a compelling combination of performance, reliability, and value. The carton manufacturing machine is a critical component of a production line, and a high-quality one can make a huge difference in the overall efficiency of the whole line.