Blister Packaging: A Perfect Fit for the Cosmetics Industry

The Hardness of Tablet: Why It Matters in Pharmaceutical Manufacturing

Your Guide to Choosing the Right Tablet Press Machine

Introduction

If you're in the pharmaceutical, nutraceutical, or even confectionery industry, the heart of your production line might very well be a tablet press machine. This crucial piece of equipment is responsible for transforming powders or granules into the precisely formed tablets that reach consumers. Choosing the right tablet press isn't just a technical decision; it's a strategic investment that directly impacts your product quality, manufacturing efficiency, and ultimately, your bottom line.

Grand Fully-Automatic-Tablet-Making-Machine

But with various types, sizes, and technologies available, finding the perfect tablet machine can feel overwhelming. To help you make an informed decision and avoid costly mistakes, we've compiled a guide built around the essential questions you'll encounter – both from potential suppliers and the ones you absolutely need to ask them.

Let's dive in and break down the process.

What Suppliers Need to Know About Your Tableting Project?

When you first contact a tablet press manufacturer or supplier, be prepared for them to ask you a series of questions. These aren't just small talk; they are critical for the supplier to understand your unique needs and recommend a tablet machine that's truly a good fit. Being prepared with this information will streamline the process and lead to better recommendations.

Understanding Your Product Specifications

The tablets you plan to produce are the starting point.

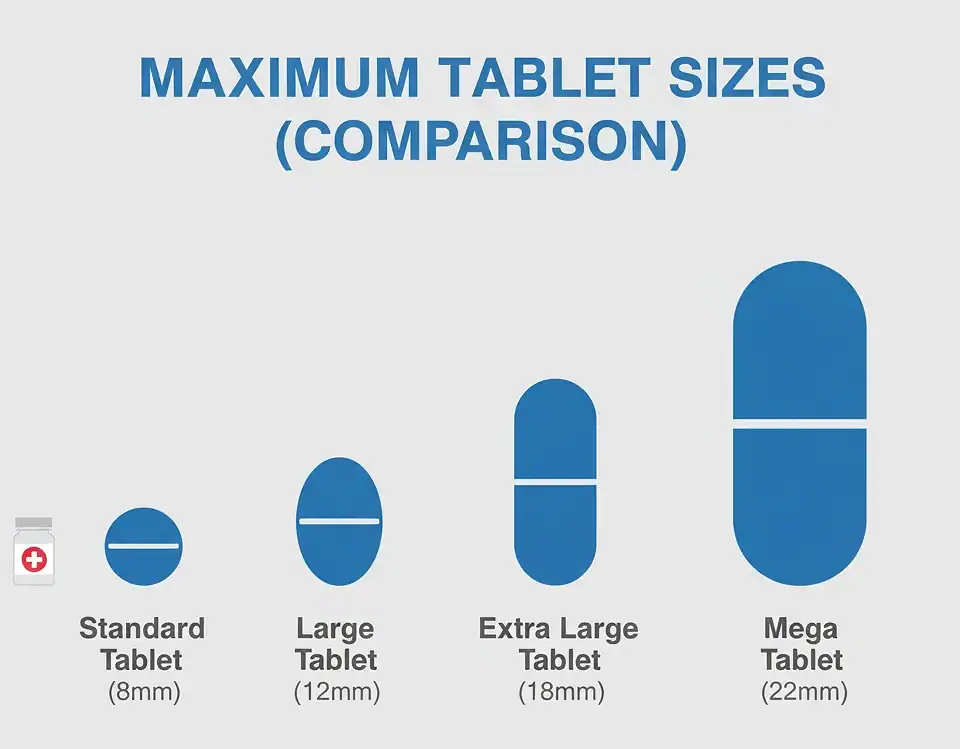

- What are your tablet size and shape requirements? Think about the diameter, thickness, and overall shape. Do you need standard round tablets, caplets, or something more complex? This dictates the tooling and the type of tablet press suitable.

- What are your target tablet weight, hardness, and thickness? These parameters relate directly to the required compression force. Different machines offer varying maximum compression forces, which must match your formulation's needs to ensure tablet integrity without capping or lamination issues.

Defining Your Production Volume Needs

Your required output is a primary driver in machine selection.

- What is your desired tablet production output (e.g., tablets per hour/day)? This is perhaps the most crucial question. It helps determine the necessary machine configuration, including the number of punches and the maximum turret speed. A single-punch pill presser is fine for R&D or small batches, while a high-speed rotary tablet press machine is essential for large-scale production.

- Do you have plans for future production growth? Don't just buy for today. If you anticipate scaling up, you need a tablet machine that can handle increased capacity, either through its inherent design or by being part of a modular system.

Detailing Your Formulation Characteristics

The nature of your raw materials significantly impacts the required tablet press technology.

- What materials will you be using for tablet production? Are they free-flowing granules, fine powders, sticky materials, or abrasive substances? Some formulations require specialized feeding systems or higher compression forces.

- Do you have any specific formulation needs? This includes sensitive ingredients, effervescent formulations requiring controlled humidity, or complex multi-layer tablets. Providing these details helps the supplier narrow down options to machines specifically designed to handle such complexities.

Your Automation and Facility Requirements

Consider how the tablet machine will fit into your existing operations.

- What level of automation are you looking for? Options range from simple manual presses (often called a basic pill presser for lab use) to semi-automatic and fully automatic systems. Your budget, required throughput, and available labor will guide this choice.

- What is the available space in your manufacturing facility? Tablet press machine footprints vary significantly. You need to ensure the machine fits comfortably in your workspace, allowing for maintenance and operator access.

- What are the power supply and electrical specifications in your facility? Electrical systems differ globally. Providing voltage, frequency, and phase information ensures the machine is compatible and operates safely.

Budget Considerations and Growth Plans

Realistic financial planning is key.

- What is your budget for the tablet press? Be transparent about your financial limits. This helps suppliers focus on feasible solutions, ensuring you get the best possible tablet press machine within your investment range.

Navigating Regulatory Landscapes

Compliance is non-negotiable in many industries.

- Do you have any specific regulatory requirements? Are you operating under GMP, cGMP, HACCP, or ISO standards? Do you need CE marking or other regional certifications? The chosen tablet machine must comply with all relevant regulations for your product and market.

Key Questions to Ask Potential Tablet Press Suppliers

Finding the right tablet press machine is a two-way street. While the supplier needs information from you, you also need to thoroughly vet their offerings and services. Asking the right questions empowers you to compare options effectively.

Matching Machine Type to Your Needs

- Based on my production needs, what type of tablet press do you recommend, and why? Don't just accept a recommendation; understand the rationale. Ask about rotary vs. single-punch types and how their characteristics (speed, tooling, versatility) align with your specific volume and formulation needs.

Assessing Material Handling Flexibility

- Can this tablet press handle the specific types of materials we use, including any challenging formulations? Get explicit confirmation. Discuss potential issues with stickiness, abrasiveness, or poor flow and how the machine addresses them (e.g., specialized feeders, turret coatings). A versatile tablet machine can save you headaches down the road.

Unpacking Unique Features and Technology

- What are the key features that make this tablet press stand out from others? This is where suppliers highlight their innovations. Look for features related to precision control, ease of changeover, data acquisition, automation, and robustness. For instance, some manufacturers, like Grand, focus on building tablet press machine models known for their robust construction, precise compression control vital for challenging materials, and integrated automation features that enhance throughput and reliability – aspects that can significantly impact your long-term operational efficiency and consistent tablet quality. Inquire about the control system interface and ease of use.

Verifying Compliance and Certifications

- Does the tablet press comply with relevant industry standards (GMP, cGMP, CE, etc.)? Can you provide documentation? Never skip this. Ensure the machine meets all necessary safety and quality benchmarks for your operations and target markets.

Understanding Support, Training, and Warranty

- What maintenance requirements does the tablet press have? Understanding the maintenance schedule and complexity is crucial for operational planning and costs. Ask about wear parts and typical replacement intervals.

- Do you provide operator training along with the purchase? Proper training ensures your team can operate the tablet press machine safely and efficiently, minimizing errors and maximizing output.

- What after-sales service and technical support are available? Inquire about troubleshooting support (remote or on-site), availability of spare parts, and response times in case of breakdowns. Reliable support minimizes costly downtime for your pill presser.

- What are the warranty terms and conditions? Understand what's covered, the duration, and the process for making a warranty claim.

Logistics: Delivery and Installation Timeline

- What is the lead time for delivery and installation of the tablet press? Get a clear timeline to plan your facility preparation and production schedule accordingly.

Making Your Informed Decision

Purchasing a tablet press machine is a significant step for any production facility. By thoroughly preparing your own project details and asking these essential questions of potential suppliers, you gain the clarity needed to evaluate options effectively.

The right tablet press will be more than just a piece of equipment; it will be a reliable workhorse that ensures consistent product quality, maximizes production efficiency, and supports your business growth for years to come. Take the time, ask the questions, and invest wisely in the heart of your tableting operation. Your product quality and bottom line will thank you.