What Makes Supercritical Fluid Extraction a Game-Changer in Pharmaceutics?

Grand Fluid Bed Dryer for Importers and Procurement Teams

Blister Type: What Can the Grand Blister Machine Produce?

When it comes to pharmaceutical and healthcare packaging, blister type plays a critical role. The right blister pack not only ensures product protection and compliance but also affects production efficiency and packaging appeal. That’s where the Grand blister machine steps in—offering reliable solutions tailored to a wide variety of blister types.

Aluminum-plastic blisters produced by grand blister machine (DPP-270) - used for packaging capsules

What Is a Blister Type?

In simple terms, blister type refers to the shape, size, and layout of the formed cavities in a blister pack. These cavities hold and protect items like tablets, capsules, or small medical devices. Each type is designed with a specific product and packaging purpose in mind.

The most common materials used include aluminum plastic (Alu-PVC) and Alu-Alu (cold-form aluminum). Depending on the product sensitivity and shelf-life requirements, the choice of blister type and material will vary.

Oral liquid blister molding

Blister Types Compatible with Grand Machines

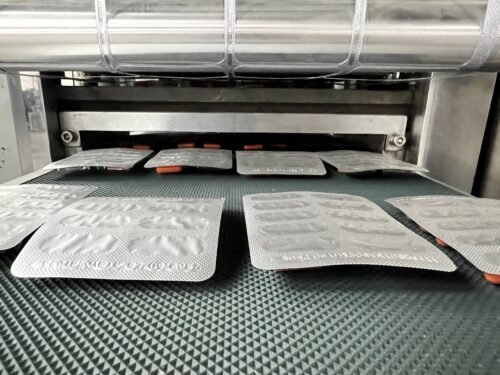

The Grand blister packing machine supports a wide range of blister types, ensuring maximum flexibility for manufacturers. Below are some of the most requested formats:

1. Flat Blister Packs

These are the classic, flat-form blister packs most commonly used for tablets and capsules. They typically include aluminum foil backing with a PVC or PVDC front.

✅ Ideal for: Standard tablets and capsules

✅ Material options: Aluminum-plastic, Alu-Alu

✅ Compatible machine: Grand DPP-260 blister machine

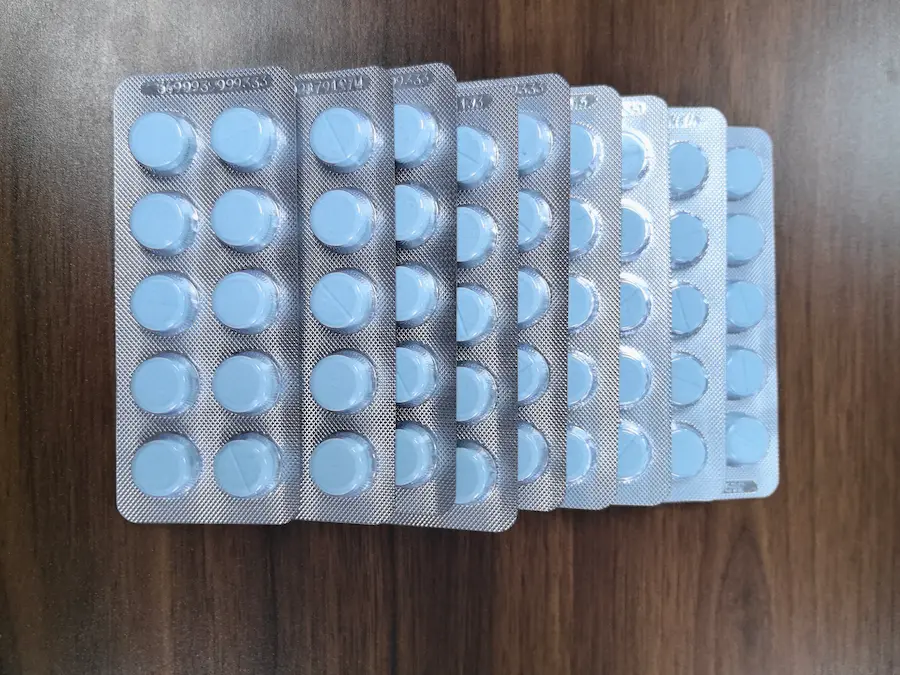

Aluminum plastic blister type(Hard capsules, soft capsules, gel capsules, tablets, etc.)

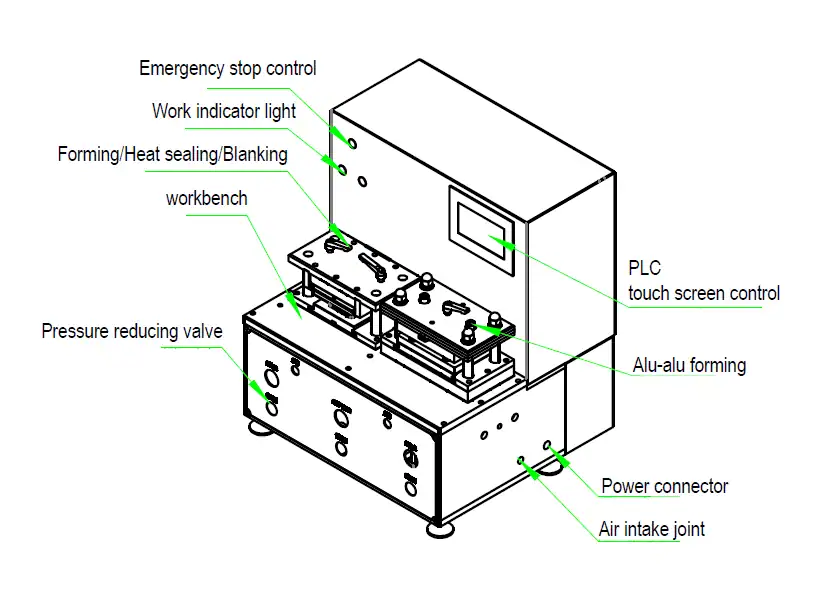

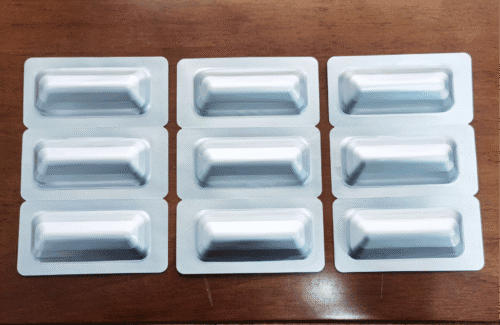

2. Aluminum-Aluminum (Alu-Alu) Blisters

For products requiring higher moisture and light protection, Alu-Alu offers superior barrier properties. These blister types are more rigid and opaque, often used in high-end or export packaging.

✅ Ideal for: Sensitive pharmaceuticals

✅ Material options: Cold-form aluminum on both sides

✅ Compatible machine: Grand DPP-260Y (Alu-Alu) model

3. Blister Bags / Wallet Packs

A more portable and user-friendly solution, blister bags combine flexible film with customized sealing patterns. These are commonly used for patient-specific doses.

✅ Ideal for: Clinical trials, hospital use

✅ Material options: Composite films or laminated foils

✅ Compatible machine: Grand customized blister line

4. Sauce and Cheese Blister Packs

Food-grade blisters designed for single-serve condiments like cheese, sauces, or creamers. These require precise forming, filling, and sealing to maintain food safety standards.

✅ Applications: Foodservice, dairy, snacks

✅ Materials: Food-grade aluminum foil and thermoform plastic

✅ Machine: Grand food blister line with CIP system

5. Eye Mask – Round Blister

Used in cosmetic and skincare industries, these round-shaped blisters maintain hygiene and product integrity while enhancing shelf appeal.

✅ Applications: Beauty and skincare masks

✅ Materials: Transparent PET, aluminum foil

✅ Machine: Grand-350(Special-shaped blister forming machine)

6. Cheese Stick – Special Shaped Blister

These custom-designed blisters cater to unique food formats like cheese sticks. They offer both product protection and user convenience.

✅ Applications: Snack food, dairy items

✅ Materials: Custom thermoform films

✅ Machine: Custom Grand shaped blister packer

Why Blister Type Matters

Matching the right blister type with the product ensures optimal protection, shelf life, and user experience. Grand’s blister machines offer flexibility, precision, and quick changeovers—enabling you to run multiple blister pack formats on a single line.

Blister Type Corresponding Machinery

Grand provides a full suite of blister packing machines, each optimized for specific blister types. Here's a quick reference:

| Blister Type | Recommended Machine | Output Rate |

|---|---|---|

| Flat Alu-PVC | DPP-260, DPP-160 | Up to 80 packs/min |

| Alu-Alu | DPP-260H | Up to 45 packs/min |

| Blister Bag / Wallet | Custom Grand line | On request |

| Sauce / Cheese Pack | Food blister machine | Up to 60 units/min |

| Round Eye Mask Blister | Special shape blister line | Up to 40 units/min |

| Cheese Stick (Shaped Blister) | Custom mold Grand packer | Custom |

All machines feature servo-driven controls, GMP-compliant design, and optional integration with printers, vision systems, and rejection units.

Final Thoughts

Whether you’re in pharmaceuticals, food, or cosmetics, choosing the right blister type can make or break your product's performance and appeal. Grand's blister machines give you the flexibility to meet changing market demands—whether you're packaging tablets, blister bags, sauces, or special-shaped blister packs.

Need help finding the perfect blister type corresponding machinery? Contact Grand for tailored solutions that grow with your business.