11 Mistakes You Make When Using a Capsule Filling Machine – Precision Filling

How a Tablet Sieving Machine Perfects Every Pill?

Grand Pill Press Machine vs. Standard: The 2025 Buyer’s Guide

Which is Best for Your Pharmaceutical Production?

Choosing the right pill press machine is one of the most critical decisions a pharmaceutical or nutraceutical manufacturer will make. The choice directly impacts production efficiency, product quality, and ultimately, your bottom line.

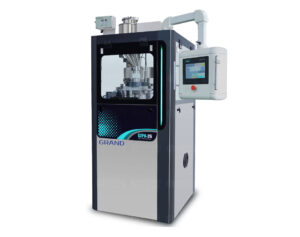

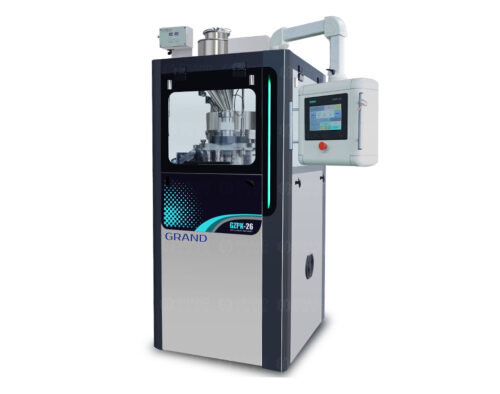

While a basic, standard tablet press might seem like a cost-effective entry point, a high-performance model like the Grand GZPK-26 Plus Rotary Tablet Press Machine often presents a far superior long-term value. This comparison will break down the key differences to help you decide which is the best machine to buy for your operations.

Performance and Throughput: The Speed of Business

A primary differentiator is raw output. Your production capacity dictates your ability to meet market demand and scale your business.

- Standard Pill Press Machine: Many entry-level or older models operate at a fixed or limited speed range. They might produce a respectable number of tablets, but they often lack the flexibility to optimize "dwell time" (the time the punch is in contact with the powder), which can lead to quality issues at higher speeds.

- Grand Rotary Tablet Press Machine: The GZPK-26 Plus is a production powerhouse, capable of producing 30,000 to 160,000 tablets per hour. With a variable speed of 11–102 RPM, operators can precisely tune the machine for the specific formulation, ensuring optimal tablet hardness and integrity without sacrificing speed. This is a key Grand Pill press advantage.

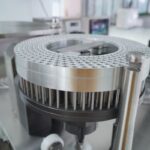

The precision-engineered turret station of the Grand GZPK-26 Plus pill press machine is designed for high-speed production.

Precision and Quality Control: Consistency is King

In pharmaceuticals, every single tablet counts. Inconsistent weight, hardness, or physical defects can lead to rejected batches, costing thousands of dollars.

- Standard Pill Presser Machine: These machines often rely on manual adjustments and mechanical controls. While functional, they are prone to minor deviations over the long run. They typically lack a pre-compression stage, increasing the risk of common problems like lamination (splitting) and capping (top layer breaking off).

- Grand Pill Press Machine: Grand elevates quality control with a two-stage compression system. A 20 kN pre-pressure force expels trapped air from the powder before the 100 kN main pressure forms a solid, flawless tablet. Coupled with a Siemens PLC and digital pressure monitoring at each station, the machine provides real-time feedback and automatic adjustments to ensure every tablet meets cGMP standards.

Automation and Ease of Use: Reducing Human Error

Complex machinery requires skilled operators, but advanced automation can significantly shorten the learning curve and reduce the chance of error.

- Standard Pill-Making Machine: Operation often requires extensive manual setup and constant supervision by a highly experienced technician. Changeovers are lengthy, and process parameters must be logged by hand, opening the door for inconsistencies.

- Grand Pill Press Machine: The user-friendly Siemens HMI (touchscreen) allows for storing recipes, monitoring all processes on one screen, and enabling automatic weight control. This level of automation means faster startups, less reliance on operator memory, and highly repeatable results, batch after batch. When looking for an alternative to complex, error-prone manual systems, this is a clear winner.

The Real Cost of Ownership: Beyond the Initial Price

When you're ready to buy a new pill tablet press, it’s tempting to look at the initial price tag as the main factor. However, this can be misleading.

Grand fully automatic tablet press can be used with the rotary tablet sieving machine and Polishing Machine to efficiently produce perfect and consistent tablets.

A standard machine might have a lower upfront cost, but consider the hidden expenses:

- Higher rate of rejected batches due to inconsistency.

- Increased downtime from longer changeovers and more frequent maintenance.

- Higher labor costs due to the need for constant, skilled supervision.

The Grand GZPK-26 Plus is engineered for maximum uptime (clients report over 95%) and efficiency. The quick-release tooling allows for a full changeover in under an hour, not half a day. Its durable construction with NSK bearings and 316L stainless steel contact parts minimizes maintenance. Over its lifespan, the Grand machine’s reliability and output deliver a significantly lower total cost of ownership.

The Verdict: Which Pill Press Machine Should You Buy?

For small-scale R&D or non-critical applications, a standard tablet press can be a functional starting point.

However, for any serious pharmaceutical or nutraceutical manufacturing operation where quality, consistency, and throughput are paramount, the Grand GZPK-26 Plus Rotary Tablet Press Machine is the superior investment. It’s more than just a pill-making machine; it's a future-proof production solution designed for maximum ROI.

Ready to see how a high-performance pill press machine can transform your production line?

Request a Quote for Your Grand Pill Press Machine Today and Inquire About Current Pricing to get a customized solution tailored to your exact needs.

FAQs for Automatic Tablet Press

1. An automatic tablet press is a big investment. Why choose one over a cheaper model?

While the initial price is higher, the return on investment comes quickly. You're paying for a lower Total Cost of Ownership (TCO) through:

Higher Output: Drastically increases production capacity.

Less Waste: Advanced controls nearly eliminate rejected batches.

Reduced Labor: Automation allows one operator to oversee production, not manually run it.

2. We run multiple products. How fast can we actually switch from one tablet to another?

Fast. Modern machines are designed for flexibility. Key features like quick-release tooling and saved digital recipes mean a complete changeover can be done in under 60 minutes, getting you back into production with minimal downtime.

3. How does this machine guarantee every tablet is perfect and meets cGMP standards?

It uses a combination of smart technology and superior design:

Pre-compression removes air to prevent capping and lamination.

Real-time pressure monitoring ensures consistent weight and hardness.

Auto-rejection systems instantly remove any out-of-spec tablets.

4. What kind of support is included after we buy the machine?

Our goal is to get you running smoothly from day one. Standard support includes:

On-site installation and commissioning by our certified technicians.

Comprehensive operator training for your team.

Full IQ/OQ validation documentation to ensure compliance.

Ongoing technical support and access to spare parts.