Tablet Coating Machine Export Case | Pharmaceutical | Health supplement

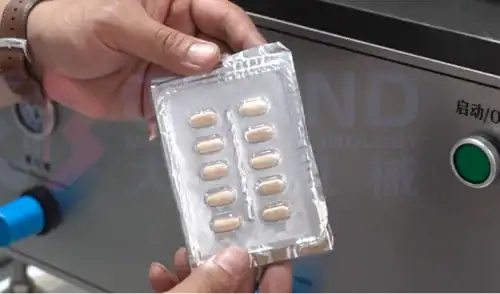

Which Blister is Best for Medicine Packing?

Why Metal Detection Machines Are Ideal for Pharmaceutical Packaging?

Introduction

Ensuring product integrity and patient safety is non-negotiable in pharmaceutical manufacturing. Contamination by metal fragments — whether introduced during formulation, tableting, filling, or packaging — can cause recalls, regulatory action, and, most importantly, harm to patients. For these reasons, industrial metal detection machines have become standard equipment on pharmaceutical packaging lines.

This article explains why metal detectors are particularly well-suited to pharmaceutical applications, details how they work, and presents brand-level and technical insights — including an expert comment from our Grand specialist, Bruce — on how modern systems differentiate aluminum foil and improve detection accuracy in pharmaceutical packaging.

Why does pharmaceutical packaging require metal detection

Pharmaceutical products pass through many mechanical stages where metal contamination can be introduced: milling, sieving, tablet compression, capsule filling, capping, and packaging. Small metal particles from tooling wear, broken dies, pins, or incidental foreign fragments represent a direct risk to product safety and regulatory compliance.

Compared with other detection methods (visual inspection, X-ray, manual checks), metal detection machines offer the following advantages that map tightly to pharmaceutical needs:

- High throughput with minimal footprint. Conveyor-integrated detectors scan products inline at commercial speeds without introducing bottlenecks.

- Sensitivity to small metal fragments. Modern detectors can detect sub-millimeter metal pieces in many product formats when configured correctly. (Specific detection limits depend on aperture size, product effect, and machine settings.)

- Gentle to the product and packaging. Unlike some inspection methods that rely on mechanical or high-energy processes, metal detection is non-destructive and suitable for delicate tablets and blister packs.

- Cost-effective compliance. Detector systems are relatively compact, consume modest energy, and have low operating costs versus repeated laboratory testing or frequent line halts.

- Regulatory alignment. Metal detection is accepted and often expected by quality systems and regulatory bodies as a preventive control in Good Manufacturing Practice (GMP) environments.

How Metal Detectors Work — detailed, pharma-focused explanation?

Industrial metal detectors used in pharmaceutical packaging are typically based on electromagnetic induction and advanced signal processing. The core components and operational flow are:

Transmit / Receive coils and electromagnetic field generation. A transmitter coil generates an alternating electromagnetic field. A matched receiver coil monitors changes in that field as products pass through the detector aperture.

Induced signal and phase response. When a conductive metallic object (ferrous, non-ferrous, or stainless steel) traverses the field, it induces eddy currents that alter the amplitude and phase of the received signal. The detector electronics analyze amplitude and phase shift to identify and characterize anomalies.

Single-frequency vs multi-frequency operation.

Single-frequency detectors operate at one frequency optimized for a balance between sensitivity and product effect rejection. They are effective in many, but not all, pharmaceutical scenarios.

Multi-frequency (simultaneous or swept) detectors operate across multiple frequencies; this increases discrimination capability between product background (product effect) and true metallic contaminants. Multi-frequency operation is especially valuable for products with complex formulation or conductive packaging (e.g., blister aluminum foil).

Product effect management. Many pharmaceutical matrices (salts, moisture, tablets with coatings, and metallic packaging such as aluminum foil) produce signals that can mask or mimic metal contamination. Modern machines use digital signal processing, automatic product learning, and phase-tracking algorithms to reduce false positives while preserving sensitivity to real contaminants. The product documentation for common industrial units lists typical detection thresholds (e.g., Fe ≥ 0.8 mm in open aperture tests), which should be validated in-line for each product and packaging combination.

Alarm, rejection, and traceability. When a suspect signal exceeds the configured threshold, the system triggers alarms and can activate automatic rejection (pushers, air blasts, stop-on-fault) and log the event for quality records and investigation.

Particular challenge: aluminum foil and blister packs

Aluminum foil — ubiquitous in blister packaging — creates a strong conductive layer that interacts with the detector’s electromagnetic field and increases the product effect. This introduces two challenges:

Reduced contrast. Conductive foil reduces the differential signal between the product baseline and a metallic fragment, potentially masking contaminants.

False positives. Movement, wrinkles, or variable foil thickness can produce spurious signals that mimic contaminants.

How modern systems overcome aluminum foil interference

Multi-frequency detection. By interrogating the product at several frequencies, the system can exploit differences in frequency response between packaging foil and discrete metal fragments, improving discrimination.

Phase-shift analysis and adaptive filtering. Advanced signal processing distinguishes the phase/amplitude signature of a continuous foil field versus localized inclusions.

Targeted calibration and product memory. Detectors can store product profiles (automatic learning) and dynamically adjust sensitivity to maintain detection capability without excessive nuisance tripping.

Expert insight — Grand’s specialist Bruce

“In pharmaceutical packaging, the ability to clearly distinguish aluminum foil from true metallic contaminants is critical. Grand’s metal detection machines employ multi-frequency methods and refined phase-tracking algorithms that substantially reduce product effect from blisters while enhancing the signal signature of discrete foreign bodies. In practice, this means fewer false rejects and more reliable detection of fragments that would otherwise evade simpler single-frequency systems.”

— Bruce, Grand expert

Bruce’s practical point reflects field experience: when manufacturers switch to well-tuned multi-frequency detectors and follow rigorous in-line validation protocols (challenge testing, calibration, and documented sensitivity verification), they reliably detect contaminants in blistered tablets and foil-wrapped products while maintaining acceptable production yields.

Why industrial metal detection machines outperform alternatives in pharma

Versus X-ray inspection: X-ray is superior for dense or layered non-metal foreign objects and for detecting glass or stone, but it is usually more expensive, requires higher energy, and can be less effective at detecting thin metallic particles in complex, conductive packaging. Metal detection is targeted, economical, and ideal for metallic contaminants — the most common foreign body in many pharmaceutical lines.

Versus manual inspection: Human inspection is inconsistent, slow, and impractical for high volumes. Metal detectors operate continuously and objectively with traceable records.

Versus magnetics or ferrous-only checks: Industrial metal detection machines identify ferrous, non-ferrous, and stainless steel contaminants — broadening the detection scope beyond magnetic capture methods.

Best practices for deploying metal detection in pharmaceutical packaging

Product-specific validation. Perform empirical sensitivity tests (using calibrated test pieces) with each product/packaging combination under production conditions and document results per GMP.

Use multi-frequency for conductive packaging. For blister packs and aluminum laminate pouches, multi-frequency detectors provide demonstrably better discrimination.

Routine calibration and verification. Schedule daily electronic checks and periodic challenge tests; log results for audit readiness.

Control of environmental noise. Isolate detectors from heavy electrical interference or mechanical vibration to avoid spurious signals.

Integrated rejection and data logging. Employ automatic rejection devices and maintain an electronic audit trail for every alarm event.

Cross-training operations and QA teams. Ensure operators understand product effect, test piece placement, and how to interpret machine diagnostics.

Evidence-based and technical literature (selection)

Peer-reviewed and industry literature consistently affirms electromagnetic and multi-frequency methods for metal detection in food and pharmaceutical lines. Journals such as Food Control, Journal of Pharmaceutical Sciences, and proceedings from packaging and sensors conferences provide empirical studies on detection thresholds, product effect mitigation, and signal-processing techniques. Incorporating these research findings into line validation strengthens technical defensibility during inspections and audits.

Conclusion and practical takeaways

Metal detection machines are well matched to the demands of pharmaceutical packaging because they combine high sensitivity, low product impact, inline operation, and cost efficiency. Modern systems — particularly multi-frequency pharmaceutical metal detectors — address the principal obstacle in blistered and foil-wrapped formats: discriminating packaging conductors (aluminum foil) from true metallic inclusions. As our Grand expert Bruce emphasizes, when well-configured and validated, Grand’s metal detection solutions deliver the precision required for robust contamination control in drug packaging.