Kenyan Delegation Visits Grand Company-Company News

The Ultimate Rotary Tablet Press Buying Guide 2025

Cost of a Liquid Filling Machine: A Comprehensive Guide

Summary

Investing in a high-performance liquid filling machine can revolutionize your production line—boosting throughput, ensuring dosage accuracy, and delivering consistent quality. Whether you’re bottling pharmaceuticals, beverages, or personal-care products, understanding the variables that drive price is the first step toward a smart purchase. Drawing on insights from Packaging World and Industrial Equipment News, this post breaks down the essentials: types, key cost drivers, and why the Grand liquid filling machine stands out for efficiency and precision.

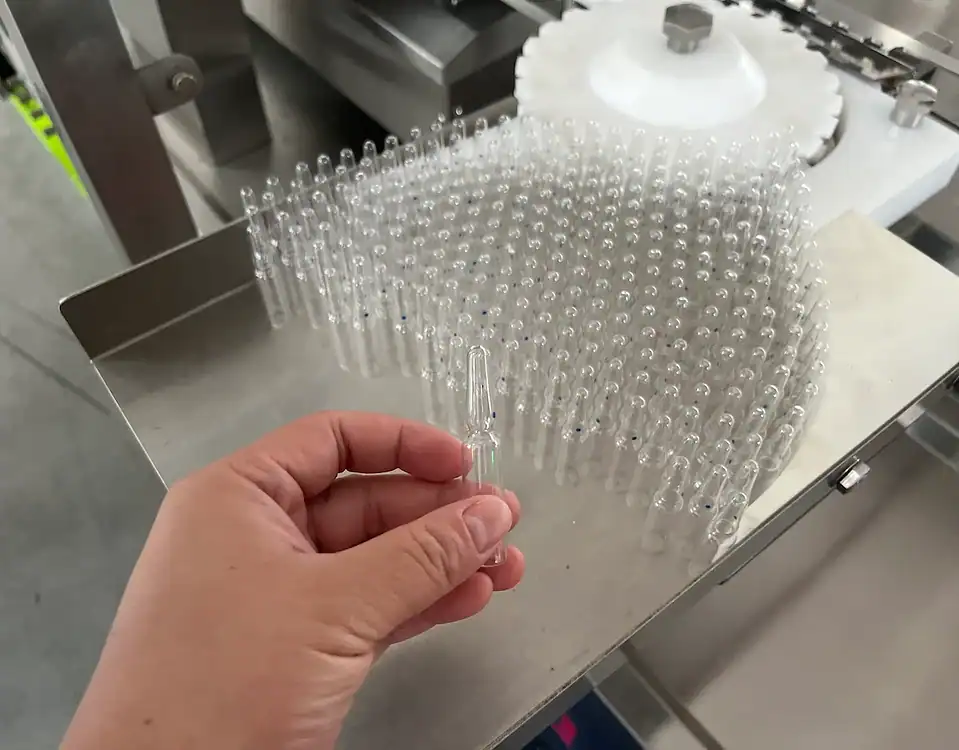

Grand Vial filling machine

1. Why Price Matters More Than Ever

In today’s hyper‑competitive manufacturing landscape, every dollar counts. A budget‑friendly model might look attractive on paper, but hidden expenses—downtime, frequent maintenance, operator training—can quickly erode your bottom line. Conversely, a slightly higher upfront investment in a durable, feature‑rich system can yield:

Reduced waste (fewer overfills and rejects)

Higher uptime (robust design, fewer breakdowns)

Scalable throughput (easy upgrades, modular add‑ons)

As noted in Packaging Technology Today, a capital‑equipped line with advanced filling tech can pay back its premium cost within 12–18 months through material savings alone.

The peristaltic pump is essential for liquid filling machines and can fill with high precision

2. Automation Levels: Manual → Semi‑Auto → Fully Automatic

Choosing the right level of automation is your first and most fundamental decision. Each tier offers distinct trade‑offs in cost, speed, and labor:

| Automation Tier | Pros | Cons | Typical Price Range (USD) |

|---|---|---|---|

| Manual | Low upfront cost, simple operation | Labor‑intensive, slower throughput | $100–$500 |

| Semi‑Automatic | Better accuracy, moderate speed | Requires operator loading/unloading | $600–$5,000 |

| Fully Automatic | Hands‑off operation, high throughput | Highest capital investment | $10,000–$100,000+ |

“Semi‑automatic fillers often hit the sweet spot for small-to-mid sized businesses,” explains Industrial Equipment News, “offering accuracy improvements without the full engineering cost of a turnkey line.”

3. Filling Technologies: Finding Your Perfect Match

Not all liquids are created equal. From water-thin syrups to viscous creams, the filling principle you choose will heavily influence cost:

Gravity Fillers

Ideal for: Low‑viscosity, clear liquids (e.g., water, juices)

Why it’s cheaper: Fewer moving parts, minimal maintenance

Pump Fillers

Ideal for: Wide viscosity range (thin oils to light gels)

Precision: ±0.5–1% volume accuracy

Piston Fillers

Ideal for: Medium to high viscosity (sauces, lotions)

Cost driver: High‑precision cylinders and seals

Overflow Fillers

Ideal for: Bottles requiring uniform fill height (cosmetics)

Trade‑off: More elaborate nozzle and valve assemblies

Vacuum Fillers

Ideal for: Foaming or viscous products (detergents, creams)

Why pricey: Vacuum pumps and vacuum‑rated valves

Net‑Weight Fillers

Ideal for: Products regulated by weight (pharma, food)

Precision: ±0.2% or better accuracy; integrated scales add cost

Insider Tip: According to Journal of Food Engineering, pump and piston technologies account for over 60% of all industrial filling installations, balancing versatility and cost‑effectiveness.

4. Key Factors That Drive Up the Price Tag

Beyond basic type and tech, these elements can make a serious dent in your budget:

Production Capacity

Machines rated for 1,000+ bottles per hour use beefier motors, stronger frames, and more sophisticated control systems.

Materials & Build Quality

304 vs. 316L stainless steel: Upgrading to 316L for aggressive chemistries can add 10–20% to the cost.

Controls & Instrumentation

PLC integration, color touchscreens, and recipe management modules enhance usability—but add $2,000–$8,000 extra.

Customization & Special Features

Heated tanks, product agitators, nitrogen purlge, clean‑in‑place (CIP) systems… each option is a bespoke add‑on.

Brand & After‑Sales Support

Recognized OEMs often bundle extended warranties, spare parts kits, and training—factored into a premium price.

Regulatory Compliance

FDA, USDA, and CE certifications involve documented testing and validation, elevating both build standards and cost.

Logistics & Installation

Heavy machinery shipping, on‑site assembly, and operator training can tack on 10–15% of the machine’s list price.

5. Real‑World Cost Comparison

Below is an illustrative price breakdown of representative models—emulating data you might find in Bottling Magazine—to highlight how specs translate into dollars:

| Model | Automation | Filling Tech | Capacity (bph) | Price (USD) | Key Feature |

|---|---|---|---|---|---|

| GFK‑160 | Manual | Micro‑pump | 600 | $99.00 | Low‑shear pump for delicate liquids |

| C1WY | Semi‑Auto | Piston | 1,200 | $600.00 | GMP‑grade 304 SS, ±0.5% tolerance |

| SGGS‑1 | Fully Auto | Peristaltic + Capper | 1,800 | $27,250.00 | Integrated capper, 304 SS enclosure |

| Grand Liquid | Fully Auto | Multi‑pump system | 3,000 | $35,000.00* | ±0.2% accuracy, 316L SS, CIP ready |

* Estimated MSRP; actual pricing depends on configuration.

Why Grand Liquid Filling Machine Rocks

The Grand liquid filling machine delivers stellar efficiency (up to 50% faster line speeds) and sub‑0.3% fill precision—ideal for pharmaceutical and high‑value cosmetics. Its modular design allows quick changeovers, slashing downtime by as much as 40% compared to legacy systems.

6. Maximizing ROI: Tips for Smart Buyers

Define Your Throughput Needs

Don’t overshoot. A machine rated for double your peak demand ties up capital and may underperform at low volumes.

Plan for Growth

Modular add‑ons—like additional nozzles or in‑line cappers—extend the life of your investment without a complete system swap.

Factor in Total Cost of Ownership (TCO)

Include energy usage, spare parts, and annual maintenance in your budget model.

Leverage Leasing or Financing

Many OEMs and equipment financiers offer attractive terms—allowing you to conserve working capital.

Seek Third‑Party Validation

Ask for case studies, line audits, or peer reviews in industry publications. A mention in Packaging Digest or Pharmaceutical Processing adds confidence.

Closing Thoughts

Selecting the right liquid filling machine means balancing immediate budget constraints against long‑term operational savings. From manual simplicity to cutting‑edge, fully automatic systems—your choice of automation level, filling technology, and optional extras will ultimately shape your price tag. And for those who demand the pinnacle of speed and accuracy, the Grand liquid filling machine offers an unbeatable combination of efficiency, precision, and modular flexibility.

Ready to explore options tailored to your product line? Contact our team for a custom quote, detailed ROI analysis, and virtual demo. Invest wisely today—and watch your production metrics soar tomorrow.