China Packaging Solutions: Top 11 Manufacturers

What is an excellent blister packaging line manufacturer?

3 Core equipments of modern Filling Production Line

Product Overview

In today's fierce market competition, filling machines & bottle capping machines have become the core equipment of filling production lines.

The equipment is made of high-quality stainless steel and meets GMP standards. All parts in contact with the product are made of 304 or 316 stainless steel.

The overall structure is compact and durable, suitable for long-term high-load operation. The equipment is reasonably designed, simple to operate, and easy to clean and maintain. Whether it is the food, beverage or pharmaceutical industry, stable production results can be obtained.

The equipment consists of three main parts:

Turntable conveyor

Multi-head filling machine

Automatic bottle capping machine

Each part uses advanced technology to ensure high precision and high efficiency.

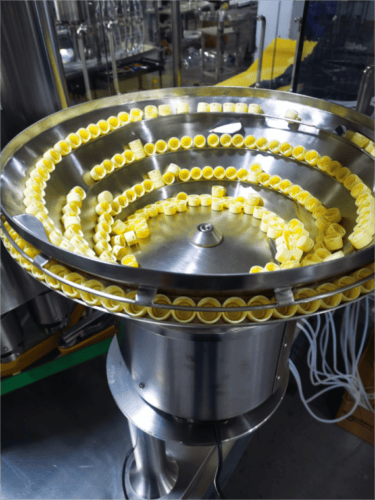

Turntable conveyor-bottle conveying tool

The turntable conveyor is used to feed manually placed bottles into the downstream conveyor belt. It relies on turntable rotation and track guidance to achieve precise bottle positioning.

Design features:

Made of 304 stainless steel

Built-in buffer function to protect the safety of the bottle body

Optional diameter 800mm to meet different production needs

The turntable can handle glass bottles and plastic bottles. The production capacity can reach 20-80 bottles/minute. The equipment has low power and consumes only 140W. Its design fully guarantees stable bottle feeding and transportation. As an important part of the automatic filling production line, the turntable conveyor provides a solid guarantee for the entire production process.

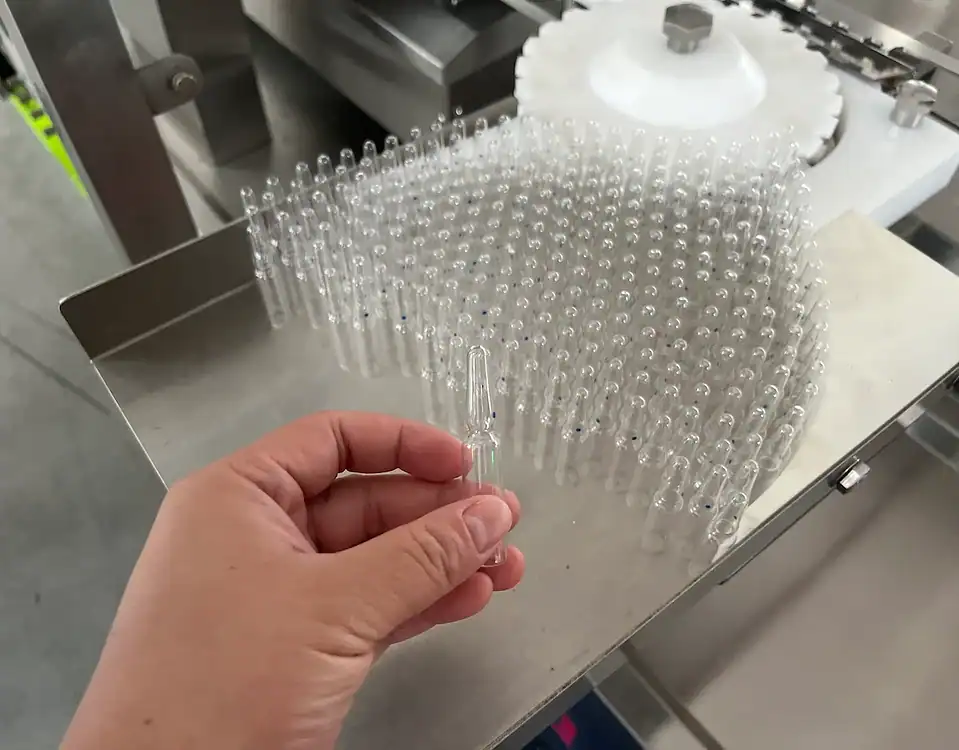

Automatic filling machine - accurate and efficient liquid filling

The automatic filling machine adopts a multi-head design and can efficiently fill various types of liquids. It is mainly suitable for 50ml to 150ml bottled liquids.

Main features:

Adopts 8-head filling system

Equipped with double star wheels to ensure stable positioning of bottles

Use ceramic pump (made of SS316L)

High filling accuracy, error control within ±0.5%

This automatic filling machine can effectively avoid liquid foaming. The filling nozzle will rise synchronously with the liquid level. In this way, the liquid will not overflow or produce foam.

Users can flexibly adjust the filling speed and liquid volume according to production needs. The quick release installation design makes it easier to disassemble and clean the equipment. As an efficient packaging equipment, the automatic filling machine saves manpower and time for the company.

Automatic bottle capping machine - accurate and safe capping system

The automatic bottle capping machine uses magnetic technology and robot arms to assist in capping. It can arrange the bottle caps neatly and assemble them automatically.

Technical highlights:

Use electromagnetic vibration to achieve single-row arrangement of bottle caps

Use 26-segment star wheel for bottle feeding

Equipped with two-roller design to ensure stable capping

With automatic stop function, the equipment automatically stops when there is no bottle

During the capping process, the equipment uses two three-claw magnetic capping heads. These capping heads can adjust the torque to ensure that each bottle cap can be firmly encapsulated. The star wheel is made of POM material, with a smooth surface and easy to clean.

The safety system can automatically stop the operation when no bottle is detected, which greatly improves product quality and equipment safety. The high precision of the automatic bottle capping machine ensures that the capping accuracy rate reaches more than 99.5%. It is an indispensable part of the modern filling production line.

Electrical control system-intelligent management

The filling and capping equipment is equipped with an advanced electrical control system. The system is mainly composed of PLC and touch screen.

Control system advantages:

Use internationally renowned brand Siemens products

Friendly operation interface, easy to use

Realize intelligent functions such as automatic stop and product counting

Long life design, high stability

In addition, various sensors such as photoelectric sensors and safety switches are integrated in the system. They can monitor the operating status of the equipment in real time. In case of abnormal situation, the system will automatically alarm and shut down.

This not only protects the equipment, but also ensures product quality. For enterprises pursuing efficient automation, intelligent control systems are an important guarantee for improving production efficiency.

Efficient production and energy saving and environmental protection

Efficient production is the core requirement of the current manufacturing industry. The equipment also performs well in energy saving.

Production advantages:

Compact process, saving production space

Simple operation, low training cost

Quick mold change design, strong adaptability

The equipment has low power and low energy consumption. The low energy consumption design is in line with the current trend of energy conservation and emission reduction.

All components have been strictly tested. The equipment not only improves production efficiency, but also reduces maintenance costs. The use of durable materials such as stainless steel and POM extends the service life of the equipment. The perfect combination of energy saving and environmental protection and efficient production is the development direction of automated filling and capping equipment in the future.

Wide range of applications

This automatic filling and capping system is suitable for multiple industries.

Food industry: filling liquid foods such as juice, milk, and condiments.

Beverage industry: production of bottled water, carbonated beverages, and functional beverages.

Pharmaceutical industry: filling liquid medicines to ensure high precision and aseptic operation.

Daily chemical industry: filling daily necessities such as detergents and cosmetics.

In each application scenario, automatic filling machines and automatic bottle capping machines can greatly improve production efficiency. They ensure the accuracy of liquid filling and the firmness of capping. Consumers have higher and higher requirements for product quality. Efficient packaging equipment just meets this demand. With the help of advanced technology, enterprises can quickly respond to market changes and achieve production transformation and upgrading.

Conclusion

This article introduces the core technologies and advantages of automatic filling machines and automatic bottle capping machines in detail. We focus on the key links such as turntable conveying, liquid filling, bottle cap assembly, and intelligent control system. Through short sentence descriptions and concise structures, this article helps you quickly understand the working principles of advanced filling production lines.