How an Automatic Liquid Filling Machine (Reagent filling and sealing) Works?

Grandpack S308: High-Speed Rotary Labeling Machine for Pharmaceutical and Medicine Bottles

Grand Tube Filling and Sealing Machine Tech vs. Standard Sealers

How the Grand Tube Filling Machine Redefines Industry Standards?

In industries from cosmetics and pharmaceuticals to adhesives and food production, the humble tube is a ubiquitous packaging powerhouse. Whether it’s toothpaste, a medicinal ointment, or a high-end cosmetic cream, the integrity of the product inside depends entirely on the quality of the filling and sealing process. While many machines can perform this basic function, not all are created equal. The difference between a standard machine and an advanced system like the Grand Toothpaste, ointment filling machine lies in the details—precision, technology, and a design philosophy rooted in excellence.

This article will take you deep inside the mechanics of a Tube filling and sealing machine. We’ll explore the question, "How does the filling and sealing machine work?" by comparing the processes of a conventional machine with the advanced, integrated solution offered by Grandpackmachine. We’ll uncover how superior technology, particularly in heating and filling, makes Grand a leader in the professional pharmaceutical and cosmetic fields.

The Standard Approach vs. The Grand Method: A Process Breakdown

A typical tube filling process follows a set of predictable steps. However, the execution of these steps is what separates average results from superior quality. Let's look at the workflow of the Grand machine to see where it elevates the standard.

Step 1: Automated Tube Loading and Precision Alignment

Ordinary Machines: Many basic machines require significant manual intervention. An operator often has to manually place each tube into the holder on the rotary turntable. This slows down production and introduces the risk of human error and contamination.

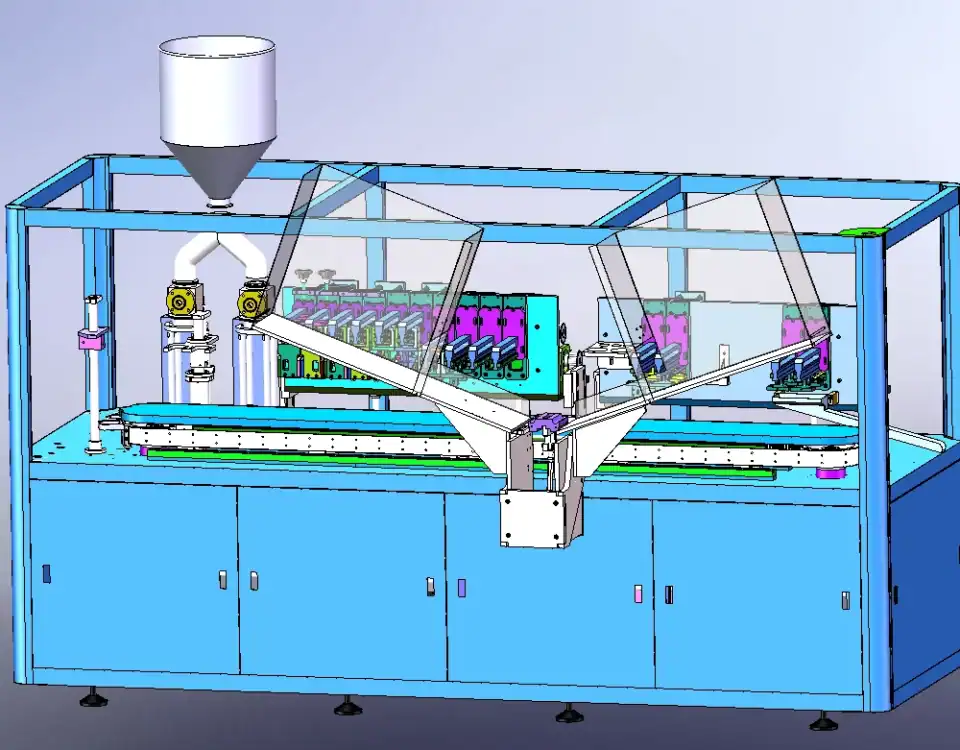

The Grand Advantage: The Grand process begins with fully automated tube loading. Tubes are arranged in a magazine and are automatically fed one by one into the 12-station precision indexing turntable. This immediately boosts efficiency and reduces labor costs.

More importantly, before filling, the machine performs an automatic mark alignment. Using a high-precision stepper motor, it rotates each tube until the registration mark (the small square on the back of the tube) is perfectly aligned. This ensures that the final seal is perfectly parallel to the tube’s printed design, a critical detail for brand presentation and professionalism.

Step 2: High-Accuracy Filling for Perfect Dosage

Ordinary Machines: Standard fillers often rely on basic pneumatic or mechanical piston pumps. While functional, these can sometimes lack the fine control needed for high-value or highly viscous products, with filling accuracy sometimes fluctuating around ±2% or more. This can lead to product waste and inconsistent dosages, a major concern in pharmaceutical applications.

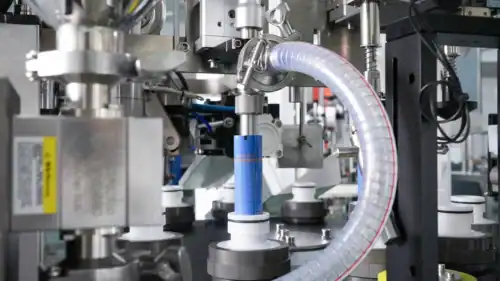

The Grand Advantage: Grand elevates filling to a science. The machine utilizes a servo-driven gear pump for quantitative filling. This advanced system offers unparalleled control and can achieve a remarkable filling accuracy of ±1%.

The filling nozzle also uses a "diving" motion, inserting itself into the tube during the fill and retracting as it finishes. This crucial feature prevents air pockets from forming in the product and eliminates messy dripping or stringing of material on the tube’s sealing area, ensuring a clean, perfect seal every time. For materials that require temperature control, the hopper can be outfitted with a heating and insulation system to maintain the perfect viscosity for filling.

The Technological Core: Revolutionary Internal Heating

This is perhaps the most significant differentiator between the Grand Ointment filling and sealing machine and its competitors.

Ordinary Machines: The vast majority of tube sealers use external heating. They clamp the outside of the tube with heated jaws to melt the plastic. The problem, as physicists and material scientists know, is heat transfer dynamics. Heat applied externally must travel through the tube wall to reach the inner surface. This creates a significant temperature gradient—the outside is much hotter than the inside. This uneven heating can lead to weak, inconsistent seals that may fail under pressure. It’s a fundamental flaw that compromises product integrity.

The Grand Advantage: Grand employs a revolutionary internal heating method. A specially designed nozzle injects hot air directly inside the tube end, heating the inner wall of the sealing area uniformly and efficiently. This is complemented by an external heated copper block for temperature stability.

Why is this so superior? Research in material science, such as that found in journals like Science on polymer dynamics, emphasizes that uniform temperature is critical for creating strong, homogenous polymer bonds. By heating the inner wall directly, the Grand machine ensures that the two surfaces to be bonded are at the optimal, consistent temperature.

The result is a seal that is dramatically stronger, cleaner, and more reliable. The finished seal is perfectly fused, neat, and can withstand significant pressure without bursting—a guarantee of quality and brand reputation.

Step 4 & 5: Flawless Sealing, Coding, and Trimming

Ordinary Machines: On simpler machines, the sealing, coding (batch/date stamping), and trimming stations can be separate or less robustly integrated. The seal quality is often entirely dependent on the flawed external heating method.

The Grand Advantage: On the Grand machine, these final steps are a seamless, synchronized conclusion to the process.

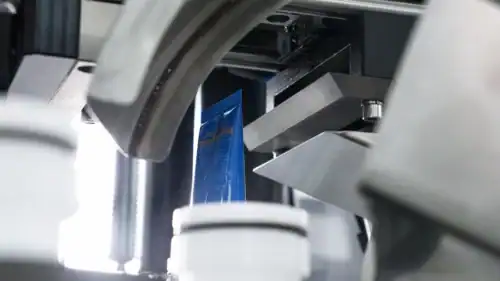

- Sealing & Coding: After internal heating, a powerful pneumatic mechanism presses the softened tube end together, simultaneously embossing it with the date or batch code using steel characters. Because the plastic is evenly heated from the inside, the embossed code is exceptionally clear and sharp, and the seal is incredibly robust.

- Trimming: An integrated cutting station then trims any excess material from the sealed end, leaving a perfectly flat, neat finish.

- Automatic Ejection: The finished product is automatically ejected from the turntable, ready for packaging.

This entire sequence—from the end of filling to the final ejection—occurs within a single rotation of the turret. This means that for every index of the 12 stations, a completed product is produced, enabling a high production capacity of up to 60 tubes per minute.

Conclusion: Engineered for Excellence

The question of "How does the filling and sealing machine work?" has a simple answer and a complex one. The simple answer is that it fills and seals tubes. But the complex, more meaningful answer lies in how well it performs that task.

An ordinary Toothpaste filling and sealing machine gets the job done. The Grand machine, however, re-engineers the process for perfection. By integrating advanced features like servo-driven filling, stepper motor alignment, and, most critically, a scientifically superior internal heating system, Grandpackmachine has created a solution that stands as a leader in the cosmetics, pharmaceutical, and chemical industries. This commitment to engineering excellence ensures that every tube is a testament to quality, safety, and precision.

References:

1、Direct Measurement of the Strength of a Covalent Bond in a Single Molecule.https://www.science.org/doi/10.1126/science.283.5408.1727

2、Role of spatula shape in the adhesion of a gecko.Xu, Q., Wan, Y., Hu, T. et al. Robust self-cleaning and micromanipulation capabilities of gecko spatulae and their bio-mimics. Nat Commun 6, 8949 (2015). https://doi.org/10.1038/ncomms9949