Vegetable Capsules: Benefits, and Capsule Filling Machine Compatibility

Grand’s Turnkey Solution for Soft Bag IV Drip Bag Production Lines

How to Make Gummy Candies at Scale: Production Lines & Equipment

How to Make Gummy Candies at Scale?

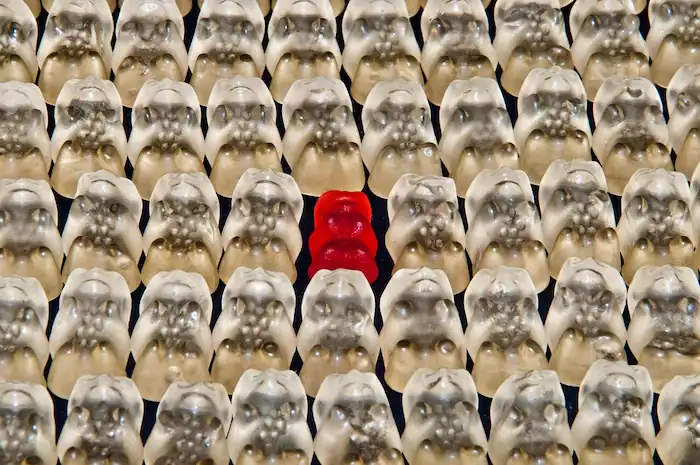

Colorful gummy candies spill out of a bottle, illustrating the booming demand that drives large-scale gummy candy production.

Scaling up the production of gummy candies from a kitchen recipe to an industrial level requires more than just a bigger pot. To make gummy candies at scale, confectionery manufacturers rely on specialized production lines that handle cooking, molding, and cooling in a continuous process. The goal is to produce consistent gummy candies in large volumes without sacrificing quality or flavor. Modern factories can turn out tens of thousands of gummies per hour by using automated equipment.

This high throughput meets the growing market demand for gummy treats – from classic fruit gummies to vitamin and CBD-infused gummy candies – all while ensuring each piece comes out with the right chewy texture and shape.

Gummy Candies Manufacturing Equipment: Key Components

A gummy candy depositor (molding machine) for small-scale production, which fills mixture into molds. In large-scale systems, depositors are a central piece of gummy candies manufacturing equipment for forming candies. Producing gummy candies at an industrial scale involves a sequence of specialized machines.

Key gummy candies manufacturing equipment includes mixing and heating tanks for dissolving gelatin, sugars, and flavors into a syrup, and precise cookers to bring that mixture to the ideal temperature and consistency. Next comes the gummy candy molding stage: an automatic depositor machine accurately doses the hot liquid candy into rows of molds (often silicone trays or starch molds) to create the desired gummy shapes. These “gummy molding” machines ensure each candy is uniform in size and weight.

A cooling tunnel or temperature-controlled room then allows the gummies to set properly as they travel along a conveyor. Once the gummy candies solidify and pop out of their molds, they may be coated lightly with oil or sugar to prevent sticking. Finally, the candies move to packaging, but not before passing quality checks for shape, weight, and flavor consistency.

The Grand soft candy production line uses the combined production equipment shown in the picture above to make soft candies at the front end, and uses an elevator and a counting machine at the back end to fill, cap, label and pack.

Benefits of an Automatic Gummy Candies Production Line

Investing in an automatic gummy candies production line offers significant advantages for confectionery equipment manufacturers and candy producers alike. Automation minimizes manual handling, which not only speeds up production but also improves hygiene and product consistency. Each step – from cooking to depositing to cooling – is synchronized, reducing bottlenecks and human error.

For example, servo-controlled depositors and PLC-driven cookers ensure that every gummy bear or fruit chew is made with repeatable precision. This leads to gummy candies that have uniform flavor distribution and texture in every batch. Automated lines also allow quick changeovers between recipes or shapes, enabling manufacturers to diversify their gummy candy offerings (think bears, worms, or vitamins) without lengthy downtime.

In short, a modern gummy candies(production line) elevates efficiency and scalability, letting producers meet high demand while maintaining strict quality standards. It’s a sweet solution that translates to lower labor costs and higher throughput.

Gummy Packaging Systems and Turnkey Solutions

A modern gummy candy packaging system uses automated counting and filling machines to quickly pack gummy candies into bottles or pouches. After production, the focus shifts to packaging these chewy confections efficiently. Gummy candies present unique packaging challenges – their sticky texture can make them clump together or stick to machinery.

That’s where specialized gummy packaging systems come in, such as vision-guided counters or multi-head weighers designed to handle gummies without jams. These machines accurately count or weigh out a specific number of gummy candies and fill bottles or bags at high speeds, ensuring each package contains the exact amount.

Integrating a gummy packaging system into the production line creates a seamless end-to-end process: from mixing ingredients to sealing finished candy bags. For confectionery businesses looking for a one-stop solution, partnering with an experienced manufacturer is key.

Grand’s gummy candies is an example of a turnkey setup that covers everything from cooking to packaging. By using a comprehensive system like Grand’s, manufacturers can confidently scale up production of gummy candies with consistent results, food safety, and efficiency. Embracing such modern production lines and equipment keeps your gummy candy manufacturing competitive in an ever-growing market.