How to Melt Gummies: A Guide to Rework & Production | Grandpack Machine

Zero Defects in Extreme Environments | GRAND Capsule Fillers & Visual Inspection Systems

Mastering Ointment Tube Filling & Sealing with the NF-150

Author: Grandpack Machine Engineering Team | Category: Pharmaceutical Packaging

In the world of semi-solids—whether it’s a high-value pharmaceutical steroid cream or a mass-market sunscreen—the tube is more than just a container. It is the delivery system.

If the seal leaks, the product oxidizes. If the fill weight varies, you violate regulatory standards. If the nozzle drips, you ruin the seal area.

For contract manufacturers (CMOs) and pharmaceutical producers, choosing a tube filling machine isn't just about "how fast does it go?" It is about Rheology and Flexibility. How does the machine handle a shear-thinning gel versus a stiff zinc oxide paste? And can it switch from aluminum to plastic tubes without an 8-hour changeover?

In this guide, we break down the engineering behind the Grandpack NF-150, a fully automatic tube filler designed not just for speed, but for the messy, complex reality of ointment production.

The Core Challenge: It’s All About the "Goop"

Before we look at the machine, we have to look at the product. Ointments and creams are non-Newtonian fluids. They don't flow like water.

Air Entrapment: If you fill a thick cream too fast without the nozzle diving to the bottom of the tube, you create air pockets. This leads to underweight tubes and product oxidation.

Stringing (The "Tail"): Sticky ointments love to leave a "string" connecting the nozzle to the tube after filling. If that string falls across the seal area, the tube will leak.

Tube Memory: Plastic tubes fight to return to their original shape; aluminum tubes dent easily. Your machine needs to handle both behaviors gently.

Why the NF-150 is "Purpose-Built" for Pharma

Many machines on the market are simply "packaging machines" adapted for tubes. The NF-150 was engineered specifically for the hygiene and flexibility required in GMP environments. Here is the professional breakdown of why this specific unit works for high-mix production.

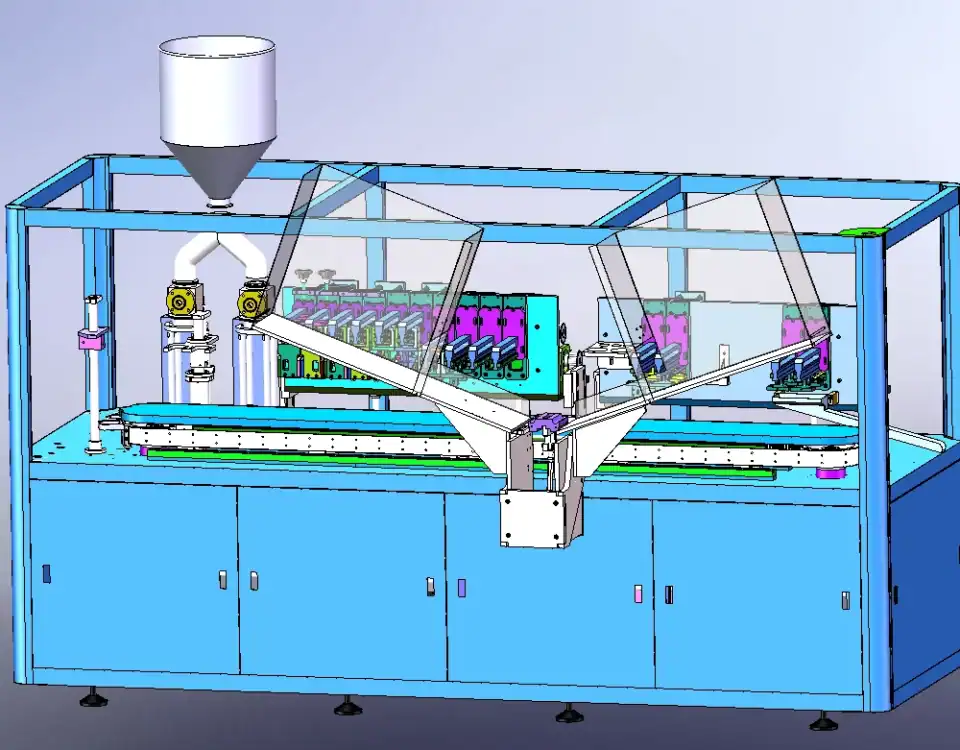

NF-150 Fully Automatic Filling and Sealing Machine (All-in-One)

1. The "Dual-Mode" Advantage (The CMO’s Dream)

Most tube fillers force you to choose a lane: Metal (Aluminum) or Plastic/Laminate. If you wanted to run both, you often needed two separate machines or a massive, expensive turret swap.

The NF-150 disrupts this. It features Dual Sealing Modes on a single chassis:

For Plastic/Laminate: It uses Hot Air + Pressure Welding (Leister-style heating) for a clean, aesthetic seal.

For Aluminum: It engages a robotic folding arm for mechanical crimping (fold-edge).

The Operational Win: You don’t need to swap major mechanical modules. For a facility running Retin-A in aluminum in the morning and a moisturizer in plastic in the afternoon, this flexibility significantly reduces CapEx and changeover downtime.

2. The Filling Core: Fighting Physics

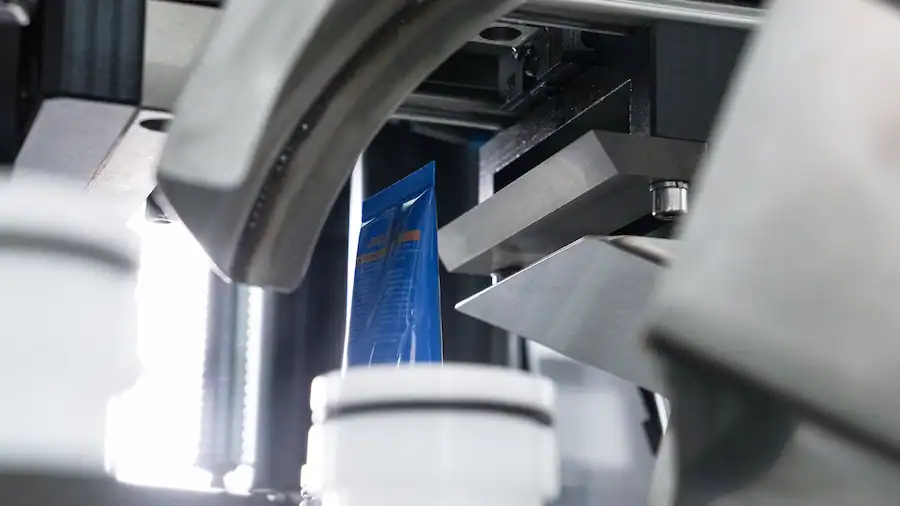

To solve the "Air" and "String" problems mentioned earlier, the NF-150 uses a Bottom-Up Filling method combined with a Blow-Cut mechanism.

Aluminum tube bending robot

How it works: The nozzle dives deep into the tube, nearly touching the bottom. As the piston pump pushes the product out, the nozzle retracts in sync with the fill level. This keeps the nozzle tip submerged, preventing air pockets.

The Anti-Drip: At the end of the dose, the machine performs a "suck-back" or uses a blow-cut blast of air to cleanly sever the product stream.

Result: A clean seal area and a ±1% filling accuracy, even on difficult viscosities.

3. GMP Design: "Clean" Above the Table

In older machines, drive chains and lubricated bearings often sat above the table, risking grease contamination falling into open tubes.

The NF-150 uses a Fully Enclosed Stainless Steel frame with a critical design choice: Oil-free sliding bearings for all components above the table. The messy mechanics (servos, cams, pneumatics) are sealed below the deck. This makes line clearance and cleaning validation (swab tests) infinitely faster for your Quality Assurance team.

Banner OCR Standard (USA)

Process Flow: From Empty Tube to Finished Good

Speed is meaningless if the process isn't stable. The NF-150 is rated for 130 tubes/minute, but in a real-world scenario with a viscous ointment, you will likely run at a stable 100–120 tubes/minute.

Swiss Leydan Dual Heating System (with Temperature Control System)

Here is the synchronized dance that happens inside the enclosure:

Loading: Tubes are pulled from a high-capacity cassette. A vacuum flip-board (servo-driven) gently places them into the pucks. Note: The vacuum pressure here is critical to avoid denting aluminum tubes.

Orientation: A banner sensor hunts for the "eye mark" (color patch) on the tube, rotating it so the front artwork faces the consumer perfectly.

The Dose: The servo-driven piston pump delivers the product.

No-Tube-No-Fill: Redundancy is key here. Two separate systems verify a tube is present. If a tube failed to load, the pump does not cycle. This saves you from cleaning 100ml of sticky ointment off the rotary table.

The Seal & Code:

Plastic: Hot air heats the inner diameter, jaws press it shut, and cold water jaws set the seal.

Aluminum: The metal is folded 3 or 4 times (saddle fold) and crimped.

Coding: Batch number and expiry are embossed into the seal area.

Ejection: The tube leaves the machine, usually "tail first," ready for the cartoner.

Line Integration: Don't Create a Bottleneck

A tube filler rarely works alone. To build a highly efficient Ointment Production Line, the NF-150 acts as the "pacemaker."

The Upstream: Connects to your manufacturing vessel via a buffer tank. Pro Tip: Ensure your buffer tank has a level sensor to pause the NF-150 if product runs low, preventing air from entering the pump.

The Downstream: The 100–120 tube/minute output is the sweet spot for most Automatic Cartoners.

If you run faster (e.g., 200/min), you need expensive continuous-motion cartoners.

At 120/min, you can use robust, intermittent-motion cartoners that are easier to maintain.

Grandpack Recommendation: We typically pair the NF-150 with a vision inspection system (to check lot codes) immediately followed by an automated cartoner and a shrink bundler. This creates a "hands-off" line from filling to palletizing.

Summary: Is the NF-150 Right for You?

The injection nozzle can be raised and lowered, and the insertion height can be freely set.

If you are a manufacturer who:

Needs to switch between Plastic and Aluminum tubes frequently.

Requires GMP compliance (Clean-in-Place friendly, separated mechanics).

Demands high accuracy (±1%) for expensive pharmaceutical ingredients.

Then the NF-150 is likely the most cost-effective high-performance solution on the market. It balances the high speed of European rotary fillers with the pragmatic, flexible engineering required for modern, diverse SKUs.

Ready to discuss your product rheology? Contact our engineering team. We don't just sell machines; we help you calculate cycle times based on your specific viscosity and tube size.