Screw cappers | Filling and capping machine

Adhering to professionalism, efficiency, and focusing on quality, Grand capping machine is your best choice to escort your production.

Product Overview

Equip your production line with our advanced capping machine solutions. From simple screw cappers to fully integrated vial filling and capping systems, we offer reliable, space‑saving equipment that boosts throughput and maintains product integrity.

Sauce bottle capping machine

Vacuum cap machin

Fully automatic vial filling and capping machine DGYG-011

Vial Filling and Capping Machine DGYG-011 is our most recommended model for pharmaceutical and industrial filling and capping needs.

- 🛠️ Innovative Vibratory‑Bowl Lifting Frame

Single‑operator setup—fully adjusted in under 5 minutes without moving footcups. 📏 Space‑Saving, Integrated Design

Footprint of just 1–2.5 m², with on‑the‑fly bottle‑height adjustment built right in.🚨 Auto‑Alarm & Shutdown on No‑Plug Detection

Inner‑stopper sensor triggers an immediate alarm or stops the machine if a cap plug is missing.🔄 Uni‑Directional Infeed & Outfeed

Bottles enter and exit in the same direction for jam‑free, ultra‑stable flow.🎯 Precision Plug‑Positioning for Glass Bottles

Compensates for diameter variances in identical‑spec glass bottles to ensure perfect placement.🛡️ Mechanical Anti‑Burst Protection + 4‑Jaw Capping Head

Prevents seal‑bursting from misaligned caps and accommodates all common cosmetic packaging specs.

Why Choose Our Vial filling and capping machine ?

Comprehensive Support

Installation, training, and 24/7 technical service.Scalable Solutions

Upgrade to multi‑head or fully automated lines as your output grows.Quality & Compliance

Components from KEYENCE, AIRTAC, Schneider, Honeywell, and Siemens.Energy Efficient

Low‑power drives and optimized pneumatic systems.

Machine Details

The program controller (PLC) is Siemens, which provides convenient operation for the filling and capping machine.

The filling structure with a high-precision ceramic pump can achieve high-speed filling with the cooperation of the wheel.

The internal top view of the integrated machine, including the bottle unscrambling structure, filling and capping structure

Grand filling and capping machine realizes fast filling and capping in a small space, and is the first choice for small and medium-sized enterprises.

DGYG-011 Core Benefits

Can be connected with labeling machine

- Space‑Saving Design

Small footprint lets you add capacity without expanding your facility. - Easy Maintenance

Quick‑release guards and modular components. - High Accuracy

Tight control over liquid filling volume and cap torque. - Versatility

Adjustable for vial heights (27–50 mm) and custom diameters. - Regulatory Ready

GMP‑compliant materials and controls.

Specifications

| Parameter | Specification |

|---|---|

| Model | DGYG-011 |

| Power Supply | 220V 50/50Hz |

| Power | 2 kW |

| Air Supply | 0.4–0.6 MPa |

| Filling Volume | 2–8 mL |

| Filling Heads | 1 |

| Filling Drive | Servo motor (optional: cylinder, electric cylinder, stepper) |

| Filling Mechanism | Ceramic shaft + PEEK gear (optional: ceramic plunger pump, peristaltic pump, piston cylinder) |

| Speed | 40–50 bottles/min |

| Bottle Height | 27–50 mm (customizable) |

| Bottle Diameter | Customizable (different diameters not interchangeable) |

| Accuracy | ±0.3–0.5% |

| Conveyor Belt | Yes |

| Bottle Aligner | Yes |

| Weight | 260 kg |

| Filling Lift | Cylinder (optional: servo) |

| Compatible Caps | Pure aluminum cap Aluminum-plastic cap Pure aluminum material cap |

| Compatible Stoppers | Butyl rubber stopper Rubber stopper Silicone stopper |

Highly efficient compatibility and customization

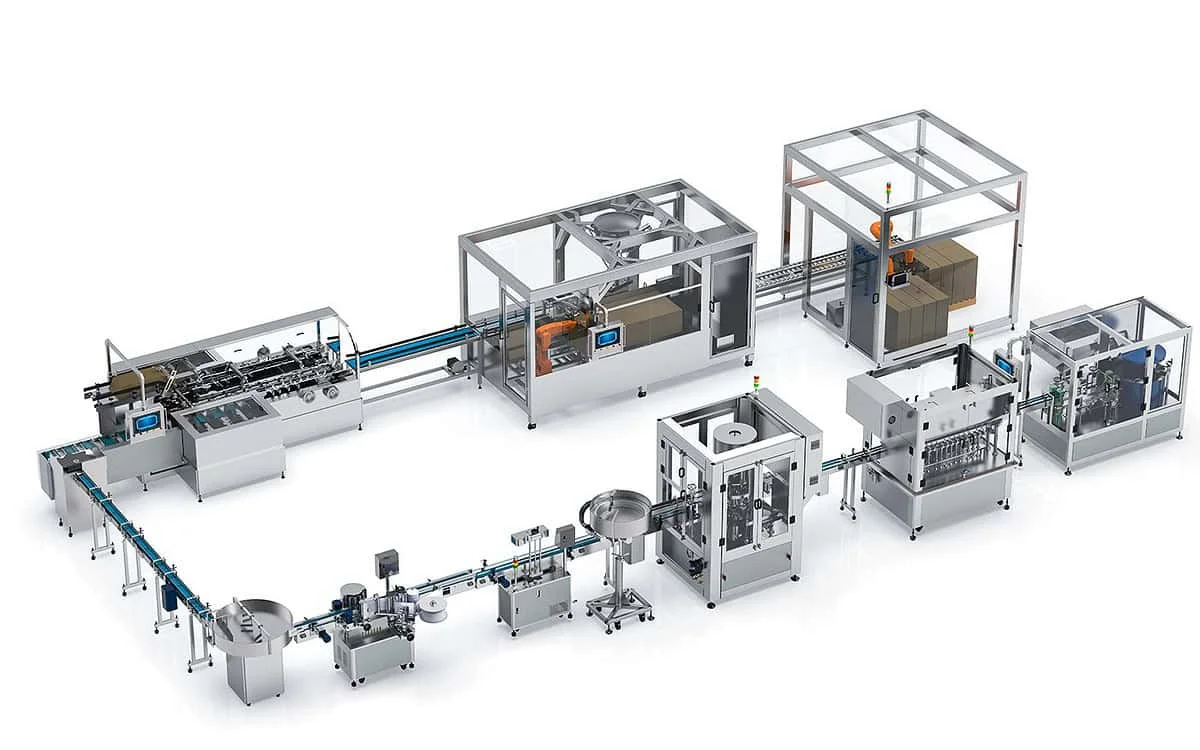

The capping machine series can be freely combined with the Grand production line and is fully compatible with the entire line, including vial packaging production lines, food filling production lines, etc.

Cartoning production line

FAQs

Contact Us