Capsule Polishing Machine – Precision Polishing and Sorting for Pharmaceutical Production

Grand Capsule Polishing Machine is a comprehensive solution that combines polishing, sorting, and lifting functions to streamline pharmaceutical production processes. Designed for high-speed operations, the machine efficiently polishes, sorts, and lifts capsules, ensuring the highest product quality and cleanliness.

Introduction to Capsule Polishing Solutions

Uphill Elevating Capsule Polisher and Sorter DGLFP-150A

The DGLFP-150A model can be connected to any Capsule Filling Machine and works with downstream devices like metal testing machines, weight testers, and appearance inspection systems, enabling an integrated, automated production process.

Triple Functionality for Efficient Production

The DGLFP-150A Capsule Polishing Machine offers triple functionality, which includes:

- Polishing: Effectively removes dust and residue, providing a smooth, clean capsule surface.

- Lifting: Ensures capsules are delivered seamlessly to the next stage in production.

- Sorting: Automatically sorts capsules, removing defective items such as empty shells, broken capsules, and body-cap separations.

This machine is a key component in achieving high-quality capsules for pharmaceutical, nutraceutical, and healthcare applications.

DGP-A Capsule Polishing Machine

Other related models

✅Contact us today to learn how the DGP-A Capsule Polishing Machine can transform your capsule production process with unmatched precision and reliability.

Key Features of the Capsule Polishing Machine

Our machine incorporates numerous advanced features, including:

- 360-degree adjustable inlet and outlet for easy alignment with filling machines and other production equipment.

- Automatic sorting mechanism that distinguishes between capsules with content, empty shells, debris, and split bodies.

- Quick-fill design for easy disassembly and cleaning, minimizing downtime during maintenance.

- Stainless steel (316L) contact parts that meet modern pharmaceutical manufacturing standards, ensuring durability and safety.

- GMP-compliant cleaning system with no dead ends, supporting thorough sanitation.

- Dust collection system to maintain a clean production environment.

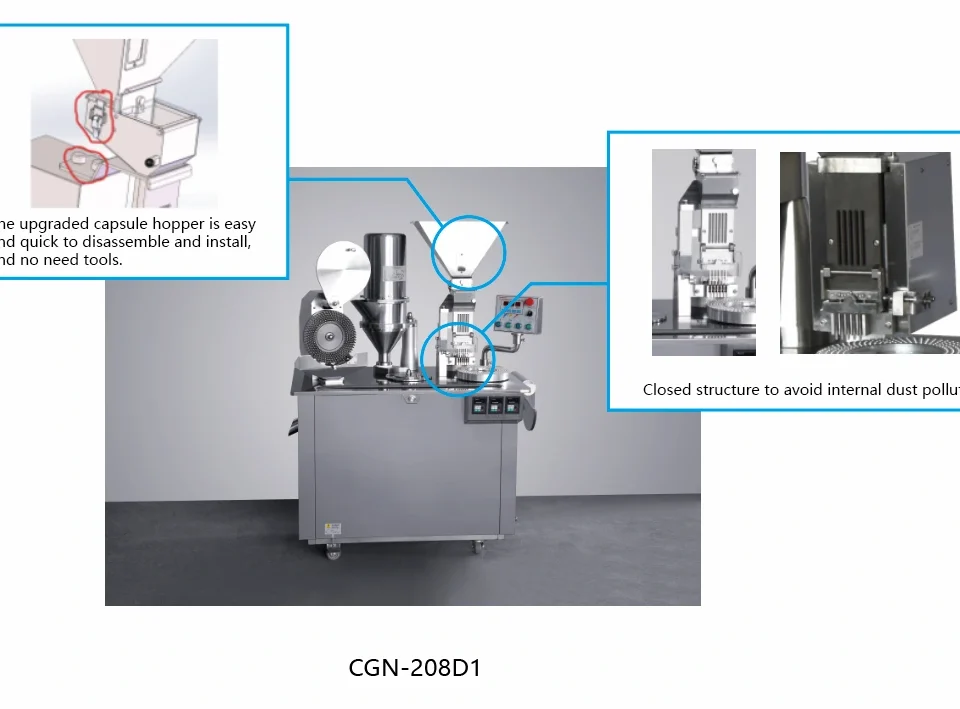

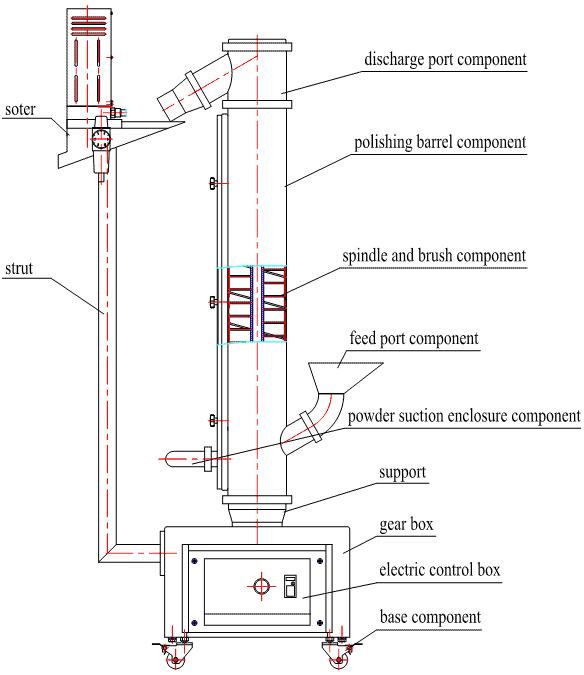

Machine parameters and internal structure

Polishing barrel components

| Model | DGLFP-150A |

|---|---|

| Applicable Capsule Models | 00#, 0#, 1#, 2#, 3#, 4# |

| Max. Production Efficiency | 300,000 pcs/h |

| Power Index | 220V 50Hz 1PH 0.40kW |

| Compressed Air | 0.3m³/min 0.3Mpa |

| Vacuum Cleaning | 3.0 m³/min -0.01Mpa |

| Dimensions | 740 x 490 x 1500 mm |

| Weight | 76 kg |

Vertical double-head capsule polishing machines, with higher production speed and high customization.

Why Choose Our Capsule Polishing Machine?

✅High Efficiency: Achieve up to 300,000 capsules per hour with precision polishing and sorting.

✅GMP Compliance: Our machine meets the highest standards of pharmaceutical manufacturing, ensuring product safety and regulatory compliance.

✅Ease of Use: The intuitive design ensures that operators can easily set up, operate, and maintain the machine.

✅Durability: Made from high-quality materials, including 316L stainless steel, our machine is built to last and withstand rigorous pharmaceutical environments.

Capsule Polishing Machine FAQS

Contact Us