Pharmaceutical Machinery

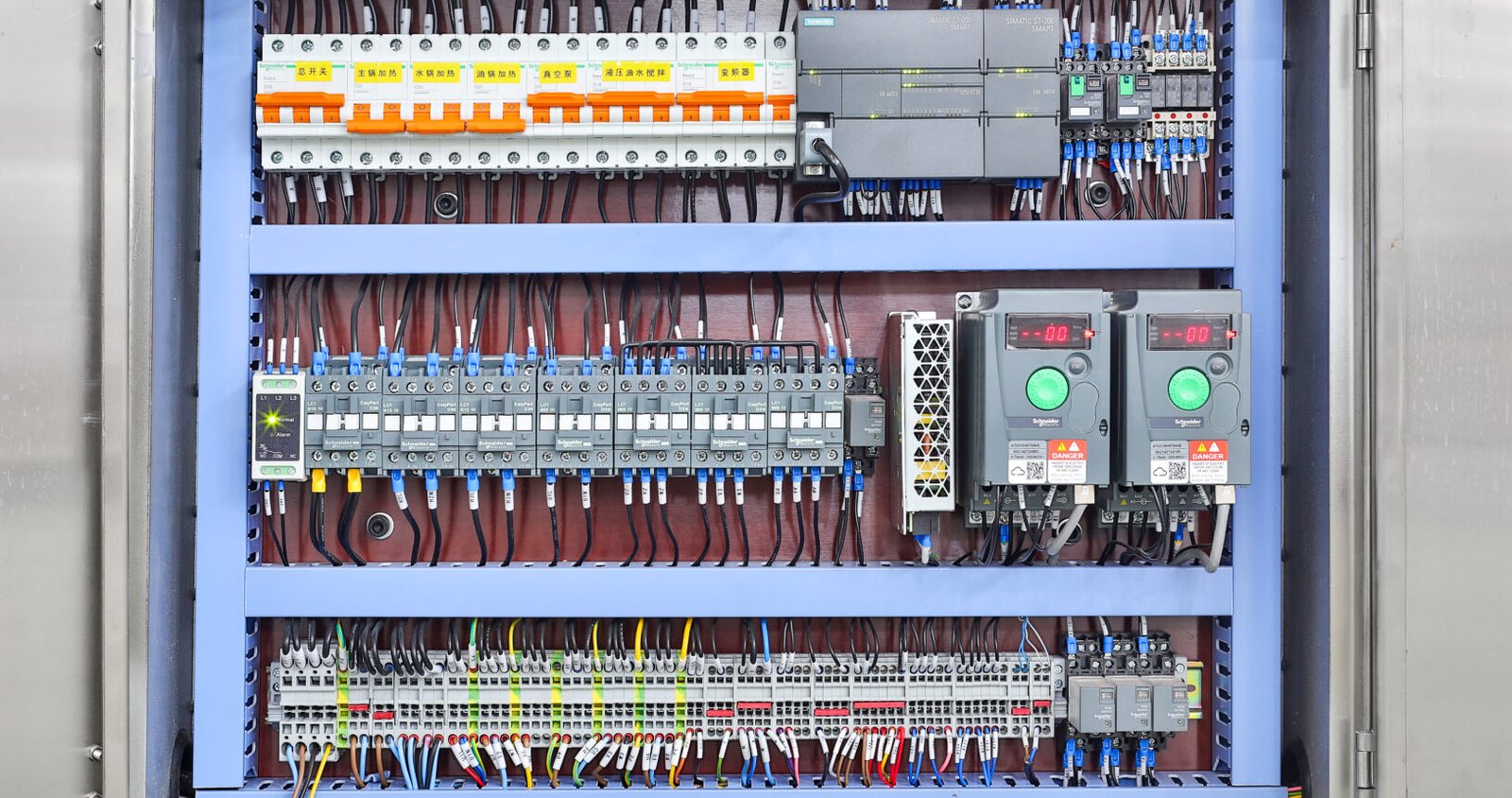

In the fast-evolving pharmaceutical industry, Pharmaceutical Machinery plays a critical role in ensuring the efficiency, safety, and consistency of production processes. At Grand, we provide a full range of pharmaceutical machinery including capsule filling machines, tablet presses, granulators, powder mixers, soft capsule making machines, and more. Whether you are looking to develop a new production line or optimize an existing one, our team can design a customized pharmaceutical production solution tailored to your manufacturing scale and needs.

Capsule Filling Machines

Our capsule filling machines are designed for precise filling, offering high efficiency and accuracy for pharmaceutical manufacturers. Capable of filling both hard and soft capsules, they ensure the perfect dosage of active ingredients in every capsule.

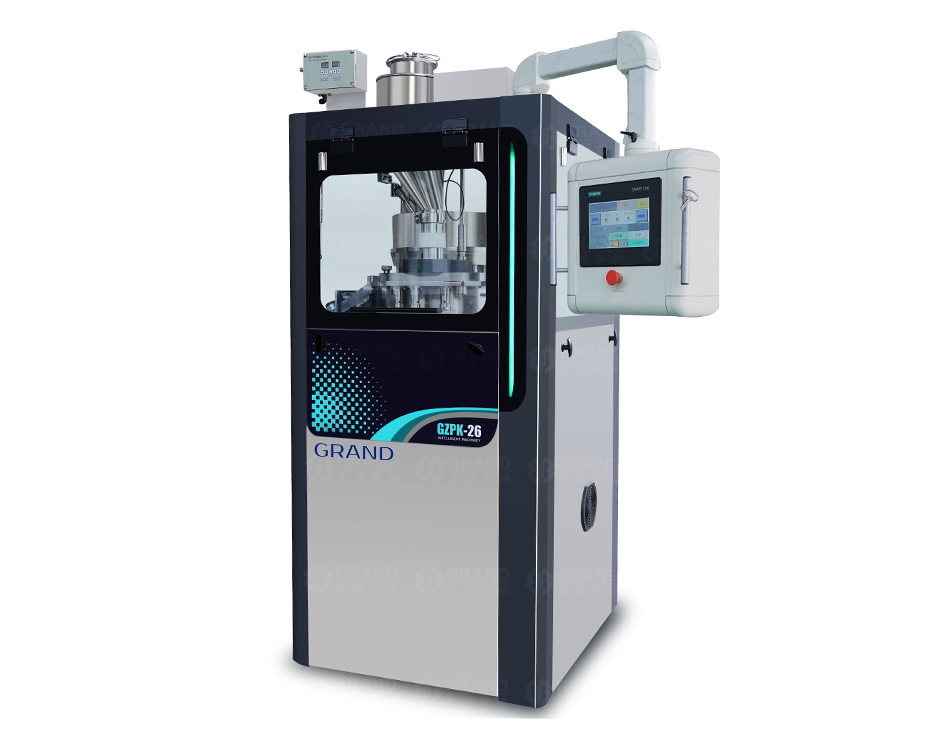

Tablet Presses

Our tablet presses deliver precise compression and excellent tablet quality. With user-friendly interfaces and robust construction, these machines can handle various tablet shapes and sizes, making them ideal for high-volume pharmaceutical production.

Granulators

Granulation is a critical step in pharmaceutical manufacturing, and our granulators offer optimal results. These machines improve the flowability and compressibility of powders, ensuring uniform tablet formation and better dosage consistency.

Powder Mixers

Our powder mixers ensure thorough blending of active pharmaceutical ingredients (APIs) and excipients, providing a homogeneous mixture necessary for the next steps in the production process. These mixers are designed for high efficiency and low energy consumption.

Grand Pharmaceutical Machinery Products

We offer a wide variety of Pharmaceutical Machinery that supports every step of the pharmaceutical production process, ensuring high-quality, efficient, and safe production. Our key equipment includes:

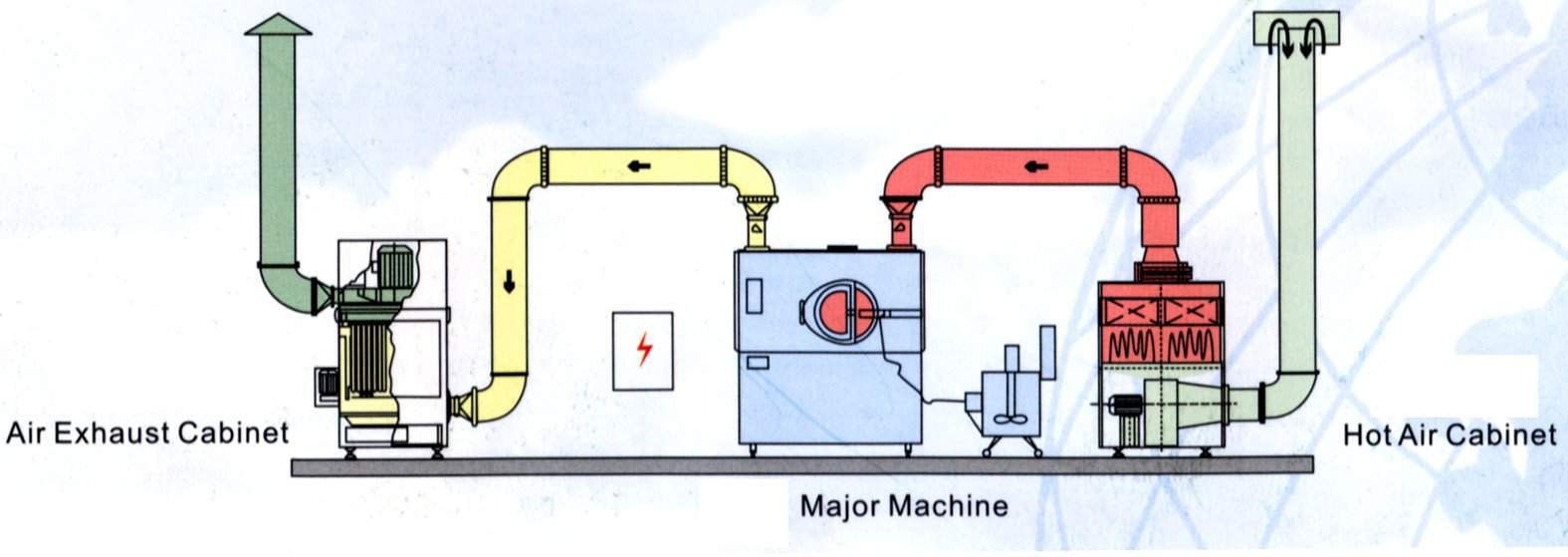

Pharmaceutical Manufacturing Process

Understanding the pharmaceutical manufacturing process is essential for selecting the right pharmaceutical machinery. Here is a step-by-step breakdown of the key processes:

1.Blending

Blending is the first step in the pharmaceutical manufacturing process, where active pharmaceutical ingredients (APIs) are mixed with excipients. Our blending machines provide efficient mixing with uniform results, essential for the consistency of the final product.

2.Compression

Compression is the process where the blended powder is compressed into tablets. Our tablet presses are equipped with advanced technology to provide precise and uniform compression, ensuring consistent tablet quality.

3.Filtration

Filtration is essential for removing impurities from pharmaceutical ingredients. Our filtration systems ensure the production of clean and high-quality raw materials for further processing.

4.Heating and Encapsulation

For certain pharmaceutical formulations, heating and encapsulation are required. Our heating equipment and encapsulation machines ensure optimal temperature control and efficient encapsulation of active ingredients in both hard and soft capsules.

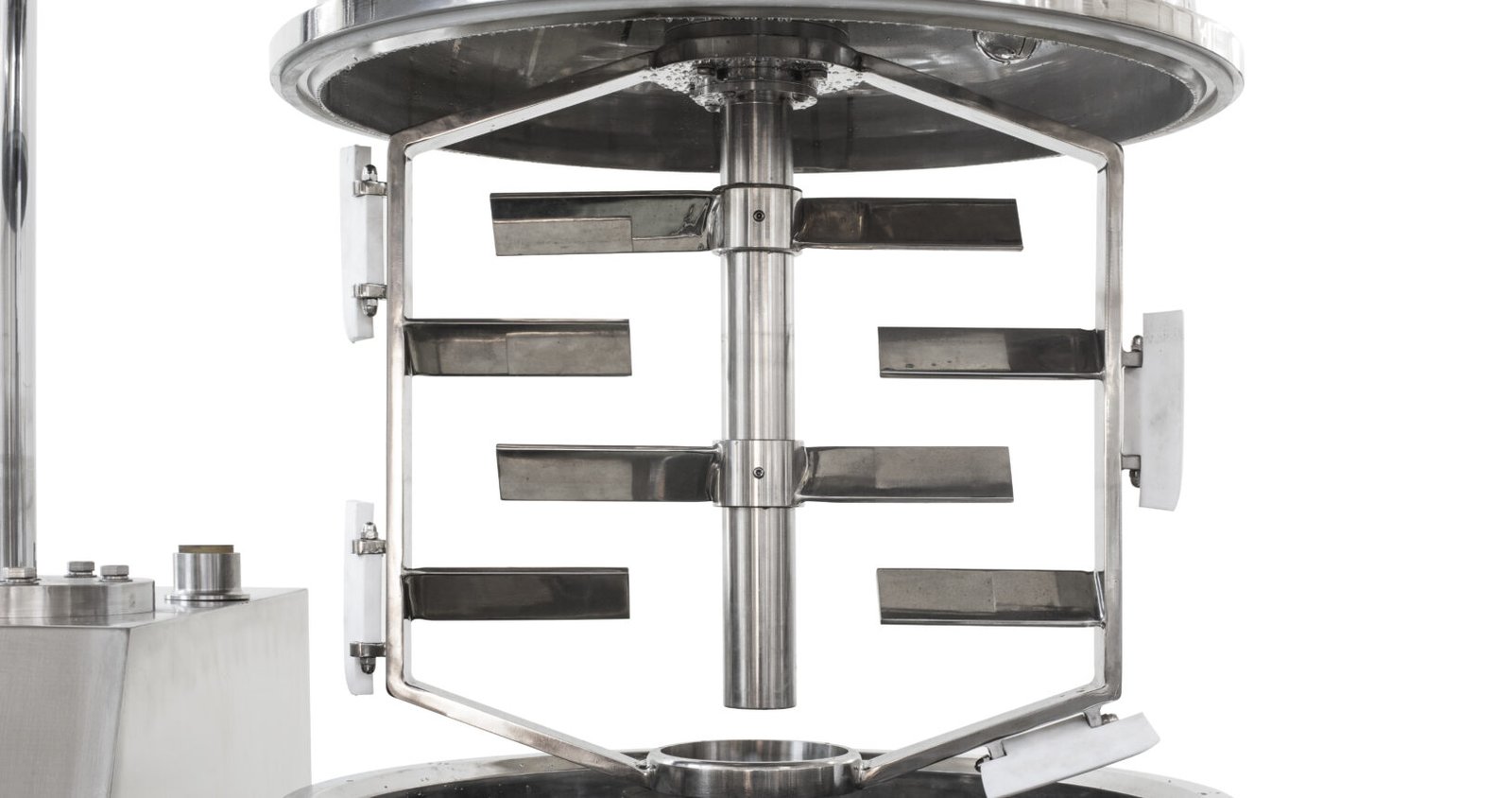

5.Shearing and Granulation

Shearing and granulation are crucial for ensuring uniformity and consistency in pharmaceutical production. Our granulators and shearing machines enhance the flowability and compressibility of powders, making them ideal for tablet formation.

6.Tableting

Tableting involves compressing granulated material into tablets. Our tablet presses ensure that tablets are accurately formed with the correct shape, size, and weight.

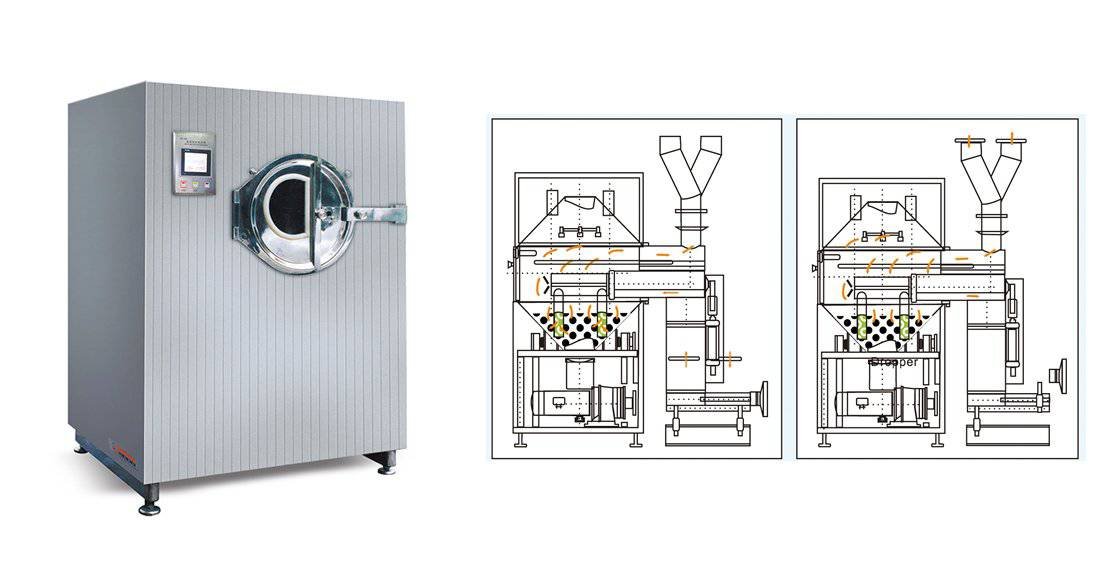

7.Coating

Our coating machines apply a protective layer on tablets, providing benefits such as improved stability, ease of swallowing, and controlled release of active ingredients.

8.Drying

Drying is necessary for removing excess moisture from tablets and powders. Our drying machines are designed to efficiently and uniformly dry products without compromising their quality.

Pharmaceutical Machinery Features:

Provide complete pharmaceutical machinery, such as: capsule filling machine, tablet press, granulator, powder mixer, soft capsule making machine......

Solution:We can develop a pharmaceutical production line for you and customized pharmaceutical production solutions based on your manufacturing scale.

Pharmaceutical steps: blending, compression, filtration, heating, encapsulation, shearing, tableting, granulation, coating, and drying.

Why Choose Us

Competitive Price

Our price is factory price and we ship directly from the factory.

Fast Delivery

We promise to ensure production-transportation-delivery within the contract period!!!

Wholesale Discount

If you purchase more than 5 pharmaceutical machines, we will give you a 30% discount.

Line Solution

In the past 10 years, we have helped over 150 pharmaceuticals customize pharmaceutical production lines and accumulated mature project experience!