Pharmaceutical Production Line&Daily chemical production line

At Grand, we specialize in designing and manufacturing pharmaceutical production lines tailored to meet the needs of small, medium, and large-scale pharmaceutical manufacturers. Our fully automated equipment is equipped with intelligent control systems, ensuring high precision, efficiency, and compliance with GMP standards.

Production Line :Customized for you

Contact Us

Develop Your Business with Grand

Grand Pharmaceutical Production Line Solutions

Focus on pharmaceutical production line solutions

Serving Small, Medium and Large pharmaceutical packaging manufactures

Fully automated equipment and intelligent control, core Electronic Components are purchased from international brands(Schneider, Siemens, Omron, Mitsubishi).

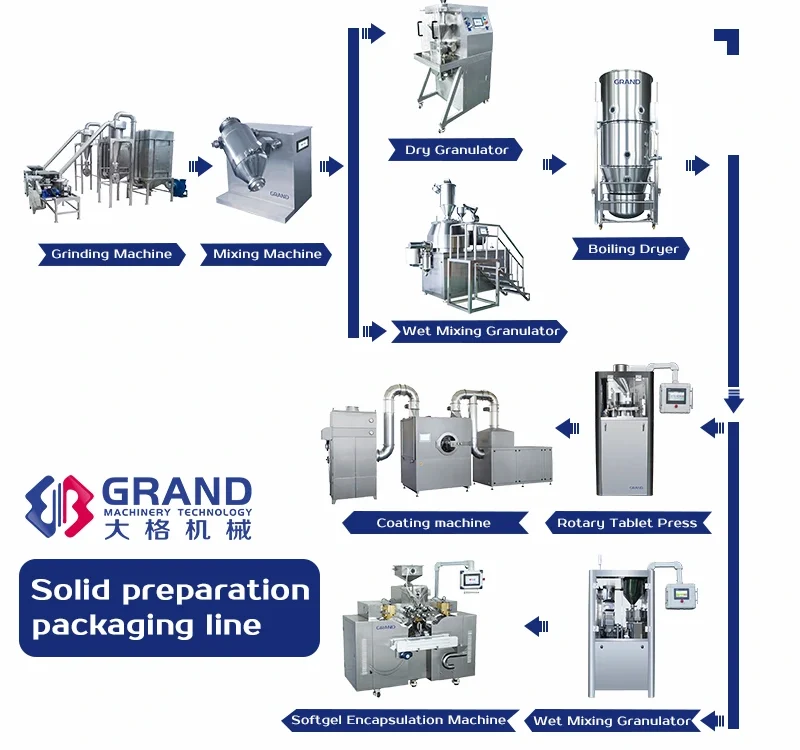

Solid Preparation Granulation Line(Tablets & Capsules)

Our tablet and capsule production lines are designed for high-speed manufacturing, ensuring precision and consistency in every dose. The production process includes:

- Blending & Mixing – Uniform mixing of active ingredients and excipients

- Granulation – Enhancing powder flowability for tablet and capsule formation

- Compression & Encapsulation – Tablet pressing and capsule filling with accurate dosage

- Coating & Polishing – Applying protective layers for controlled release and better appearance

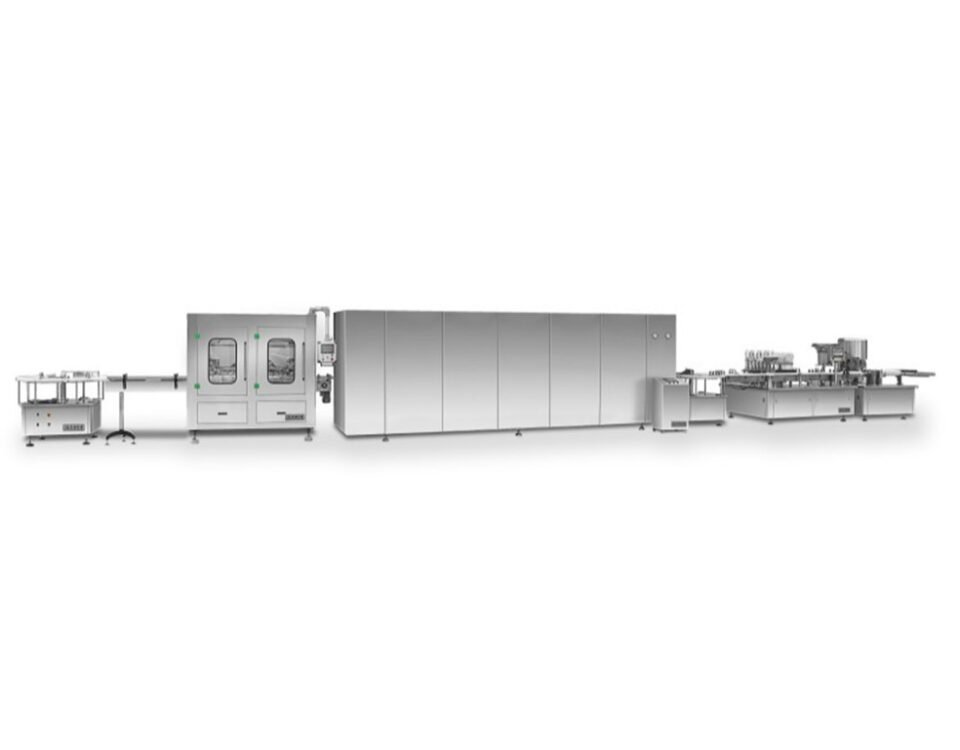

Liquid Pharmaceutical Production Line

Our liquid pharmaceutical production line ensures the safe and efficient production of syrups, suspensions, injectables, and eye drops. The process includes:

- Dissolution & Mixing – Ensuring active ingredients dissolve uniformly

- Filtration & Sterilization – Removing impurities and ensuring product sterility

- Filling & Capping – High-precision filling of bottles, ampoules, and vials

- Labeling & Packaging – Final product inspection and packaging for distribution

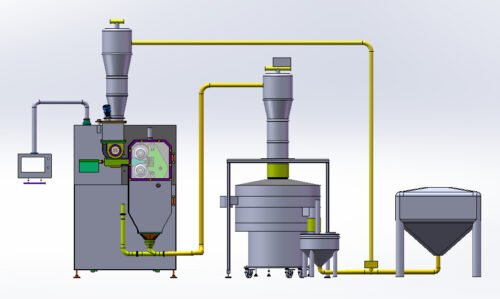

Powder & Granule Production Line

For powdered medications, granules, and dry suspensions, our advanced pharmaceutical powder processing equipment provides:

- Powder Mixing & Blending – Achieving homogeneity for consistent dosage

- Drying & Granulation – Optimizing powder properties for processing

- Filling & Packaging – Ensuring precise weight and contamination-free packaging

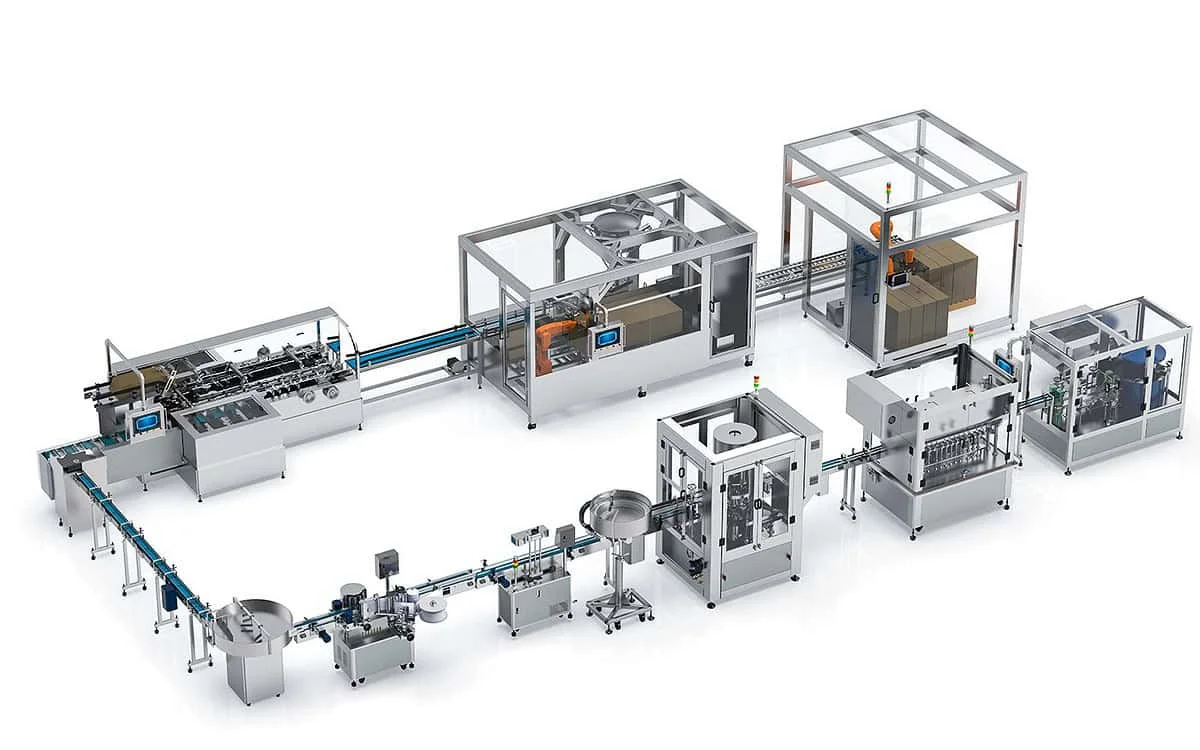

Automatic Filling Machine (line)for Cosmetics & Skincare

The GF-600 Automatic Filling Machine is a fully servo-controlled, modular filling solution specially designed for cosmetic, skincare, and personal care products. Supporting both automatic and manual modes, it ensures high efficiency, hygiene, and flexibility in bottle filling processes.

Core Application: small bottle filling for serums, lotions, essences, ampoules, toners, and more.

Put container → Blowing and sucking cleaning container → Mold return system → Servo filling system → Automatic pressing inner plug → Automatic screwing pump head → Automatic capping → Finished product removal

Pharmaceutical Production Line Features

Focus on pharmaceutical production line solutions

Serving Small, Medium and Large pharmaceutical packaging manufactures

Fully automated equipment and intelligent control, core Electronic Components are purchased from international brands(Schneider, Siemens, Omron, Mitsubishi).

Why Choose Us

Multiple Options Available

We provide complete pharmaceutical packaging lines, for more details, you can check our catalog above to choose one.

Customization

We will customize reasonable pharmaceutical packaging line solutions based on your pharmaceutical factory size and budget.

One-Stop Installation

After understanding your needs, we will develop different capsule filling line solutions to help you run the factory.

Lifetime After-Sales

Once you choose Grand!!! We support lifetime after-sales service, free replacement accessories within 10 years