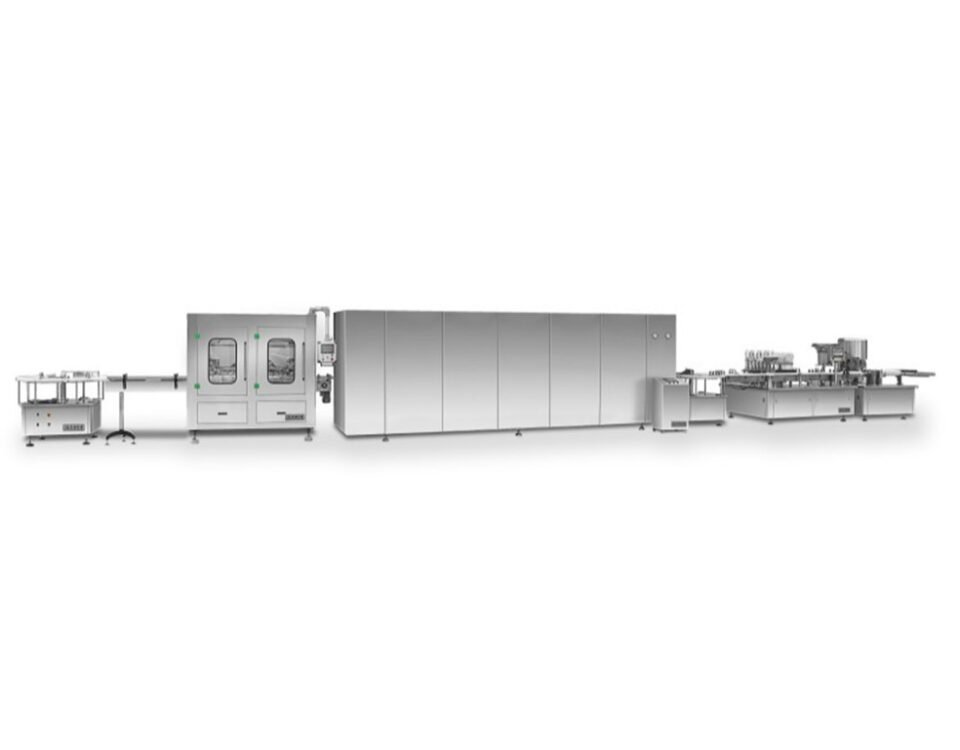

Ampoule Filling Line: Integrated Washing, Drying, Filling & Sealing

Experience seamless production with Grand’s ampoule filling line. This compact system handles 1–20 ml ampoules. It completes water rinsing, ultrasonic cleaning, drying, sterilization, filling, and sealing in one continuous process. It meets GMP standards and boosts your output.

Contact Us

Develop Your Business with Grand

The video shows the cleaning, drying and filling process of vials, which can also be replaced with ampoules.

This Ampoule Filling Line can also be perfectly connected to the Grand cartoning machine series (case packing and palletizing can also be added) to achieve the entire process from filling to cartoning.

Overview of the Ampoule Filling Line

Our ampoule filling line merges three core machines into one workflow:

QCLX Series Vertical Ultrasonic Washing Machine: Delivers consistent cleaning using ultrasonic waves and rinse cycles.

SGZ Series Tunnel Hot-Air Circulation Sterilization & Drying Oven: Provides precise temperature control for rapid drying and sterilization.

AGF Series Vertical Ampoule Filling & Sealing Machine: Achieves accurate filling and airtight sealing of ampoules.

This all-in-one line fits small labs and large plants. It occupies minimal floor space. It cleans easily and integrates into your clean-room environment.

🔧 Automatic Filling Machine Technical Specifications

| Parameter | QCLX100+SGZ600/60+AGF10 | QCLX100+SGZ600/60+AGF12 | QCLX120+SGZ600/60+AGF16 |

|---|---|---|---|

| Ampoule Volume | 1–20 ml standard | 1–20 ml standard | 1–20 ml standard; 1–2 ml option |

| Output (1–2 ml) | 16,000–22,000 pcs/hr | 22,000–28,000 pcs/hr | 26,000–34,000 pcs/hr |

| Output (5–10 ml) | 8,000–12,000 pcs/hr | 12,000–18,000 pcs/hr | 15,000–20,000 pcs/hr |

| Clarity | > 99% | > 99% | > 99% |

| Breakage Rate | ≤ 1% (whole line) | ≤ 1% | ≤ 1% |

| Filling Precision | ± 0.5–2% | ± 0.5–2% | ± 0.5–2% |

| Water & Pressure | 0.2–0.4 MPa; 0.6–1.0 m³/h | 0.2–0.4 MPa; 0.6–1.0 m³/h | 0.2–0.4 MPa; 0.6–1.0 m³/h |

| Compressed Air | 0.3–0.6 MPa; 35–80 m³/h | 0.3–0.6 MPa; 35–80 m³/h | 0.3–0.6 MPa; 35–80 m³/h |

| Gas for Sealing | Liquefied gas + O₂ or oxyhydrogen | Natural gas + O₂ or oxyhydrogen | Natural gas + O₂ or oxyhydrogen |

| Power | ~ 72 kW, 380 V/50 Hz | ~ 91 kW, 380 V/50 Hz | ~ 91 kW, 380 V/50 Hz |

| Footprint (L×W×H) | 9,940×2,260×2,445 mm | 10,100×2,260×2,445 mm | 10,600×2,260×2,445 mm |

Key Features

- Compact & Aesthetic Design

The sleek frame blends into GMP clean rooms. It saves floor space and simplifies cleaning. - High Throughput & Flexibility

Capable of 16,000–34,000 pcs/hr for 1–2 ml and up to 40,000 pcs/hr for 5–10 ml ampoules. Adjust speed to match demand. - Ultrasonic Washing & Rinsing

Ensures > 99% clarity. Removes particles and residues. - Precise Drying & Sterilization

Maintains stable temperature in the SGZ hot-air oven. Achieves consistent microbial control. - Accurate Filling & Sealing

Fills within ± 0.5–2% per pharmacopoeia. Uses liquefied gas or oxyhydrogen for perfect seals. - GMP-Compliant Construction

Meets national drug-product quality management regulations. Provides full traceability and validation.

How Our Automatic Filling Machine(Line) Works?

Process flow chart :

Put ampoules → Water spray rinse → Ultrasonic cleaning → Secondary water rinse → Air blow–dry → Hot-air circulation drying & sterilization→ Cooling→ Servo filling&Sealing → Vision inspection / Breakage detection Finished → product removal

Why Choose Grand Pharmaceutical Production Line

✅Proven Reliability

Our ampoule filling machine manufacturers deliver stable performance.

✅One-Stop Solution

We provide ampoule washing machine, ampoules filling & sealing machines, and full integration.

✅Expert Support

Get rapid commissioning and 24/7 service.

✅GMP Expertise

We ensure full compliance with national regulations.

✅Scalable Design

Expand capacity by adding modules or parallel lines.

📞 Service & Technical Suppor

Operation training

For factory operators, we provide free technical training, covering daily operations, product switching processes and safety specifications, helping the team to quickly master automated filling skills.

Spare parts and consumables supply

Common wearing parts (seals, valves, pipes, etc.) are kept in 24-hour response and distribution, and genuine consumables are provided to ensure continuous worry-free production.

Regular maintenance and maintenance

Provide annual inspection packages, including equipment cleaning, lubrication, replacement of wearing parts and performance evaluation, to extend machine life and reduce failure rates.

Upgrade and customized development

For future capacity expansion or new product needs, we provide modular upgrade solutions and secondary development services to keep your filling line at the leading level in the industry.

❓Frequently Asked Questions (FAQs)

Q1: What is an ampoule filling line?

An ampoule filling line integrates washing, drying, filling, and sealing. You feed empty ampoules and get finished products.

Q2: Which volumes can Grand’s line handle?

It handles 1–20 ml ampoules, with optional modules for 1–2 ml small doses.

Q3: How accurate is the filling?

Our filling precision meets ± 0.5–2% per the pharmacopoeia standard.

Q4: What cleaning methods does it use?

It uses ultrasonic cleaning, water rinse, air blow, and hot-air sterilization.

Q5: Is it GMP-compliant?

Yes. It meets current national drug-production quality management standards.