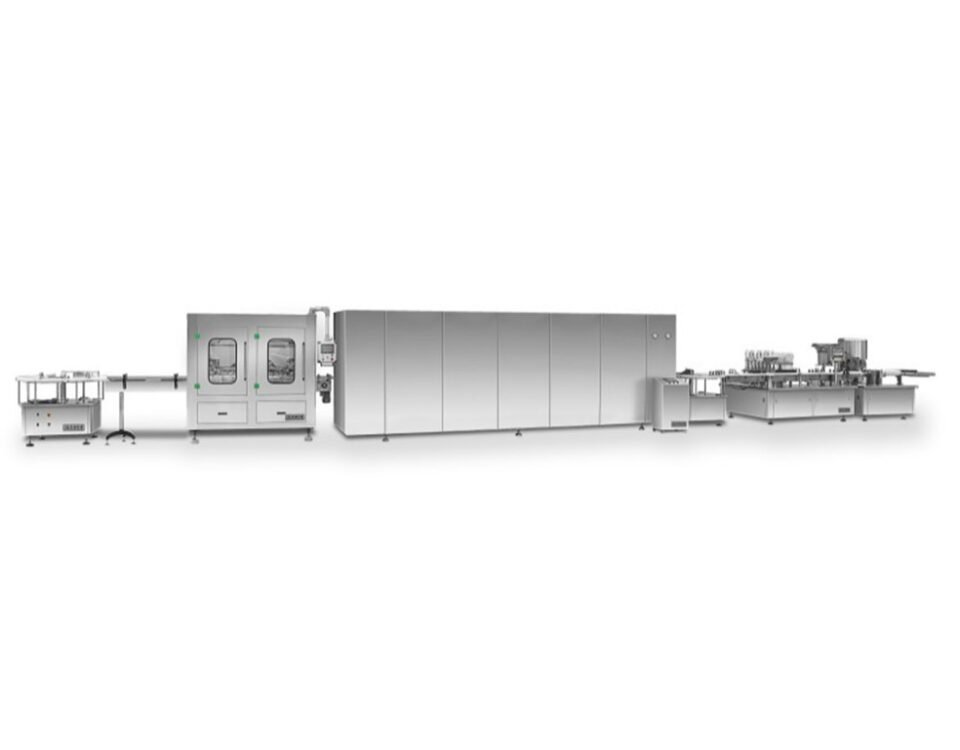

Gummy Production Line

Grand’s gummy production line is designed to produce candies of different shapes. If you need such production line, please feel free to contact us.

SE-300 Gummy Production Line Features

High degree of automation: The SE-300 Gummy Production Line adopts advanced automation technology to achieve efficient and automated operation throughout the process.

High versatility: It supports the production of various types and shapes of soft candies, and can quickly switch product types by changing molds and adjusting parameters.

Strict hygiene standards: The production line is designed in accordance with food-grade hygiene standards and is made of 304 stainless steel, which is easy to clean and maintain to ensure product safety and quality.

Energy saving and environmental protection: The SE-300 Gummy Production Line is equipped with energy-saving equipment to optimize energy consumption.

Video

Specifications

| Model | SE-150 | SE-300 | SE-400 |

| Output: | 150kgs/h | 300kgs/h | 450kgs/h |

| Sugar Block Weight: | 5g | 5g | 5g |

| Depositing Times: | 30-45n/min | 30-45n/min | 30-45n/min |

| Steam Consumption: | 100kgs/h | 200kgs/h | 300kgs/h |

| Steam Pressure: | 0.20.6Mpa | 0.2-0.6Mpa | 0.2-0.6Mpa |

| Compressed air Consumption: | 0.2mmin | 0.4m/min | 0.6 m³/min |

| Compressed Air Pressure: | 0.4-06Mpa | 0.4-06Mpa | 0.4-06Mpa |

| Temperature: | 20-25°℃ | 20-25°℃ | 20-25℃ |

| Humidity: | 55% | 55% | 55% |

| Total Power: | 18KW/380 | 20KW/380V | 22KW/380V |

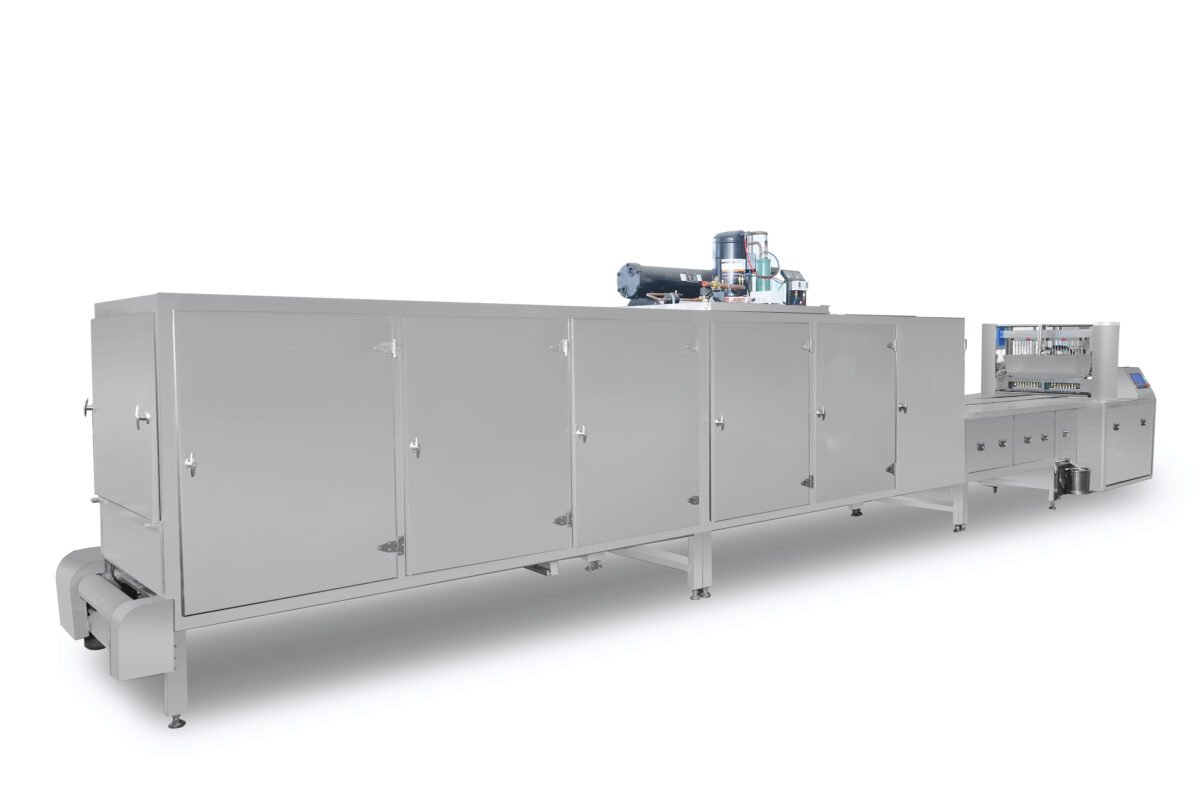

| Production Line Total length: | 13.5m | 14m | 15m |

Machine Details

Control Panel

Peristaltic Pumps

Gummy Module

The Ultimate Guide To Gummy Candy Production Line

Gummy candy has successfully become one of the most favored worldwide treats that are popular among people of all ages due to this Gummy candy’s chewy texture, its bright colors and its fun shapes.

Despite appearing simple, there is a complex production process behind each gummy bear, ring, or worm that turns elemental ingredients into the same uniform, mouth-delightful candies you find on the shelves.

A gummy candy production line makes this process possible with a series of machines that fits together to form one big machine.....

FAQS

Here are some FAQs

and packaging to ensure efficient and smooth operations throughout the production process.

Contact Us

-500x333.jpg)