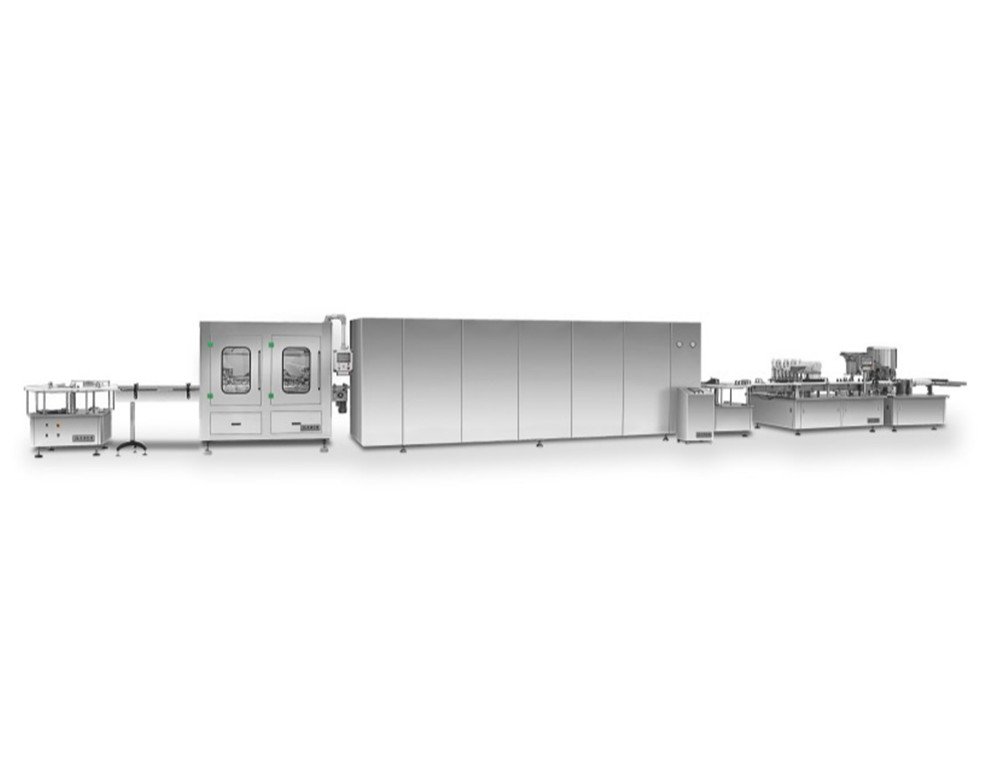

Oral liquid filling line

Complete GMP-compliant oral liquid filling line for 30-50ml glass bottles. Achieve 99.9% capping accuracy, ≤0.1% breakage rate, and 180℃ sterilization. Custom configurations with PLC control. Get expert solution now!

Contact Us

Develop Your Business with Grand

Why Choose Our Oral Liquid Filling Line?

Precision Filling Technology

12-head rotary filling system

Complies with Chinese Pharmacopoeia standards

±0.5% volume accuracy

Intelligent Error Prevention

Photoelectric sensors(Full monitoring)

Auto-stop on bottle jams(Bottle breakage rate ≤ 0.1%)

Real-time production data dashboard

Flexible Configuration

- Modular design supports full process customization of bottle washing → sterilization → filling → capping → labeling

- Compatible with various pallet specifications from Φ600-1200mm (emphasis on compatibility with IMA/Bosch equipment)

Oral Liquid Filling Line Components & Specifications

| Parameter | Specification |

|---|---|

| Applicable Specifications | 30-50ml (oral liquid bottles) |

| Production Capacity | 10,000-12,000 bottles/hour |

| Sterilization Capacity | Sterilization Temperature: 180°C Sterilization Time: ≥6min |

| Bottle Breakage Rate | ≤0.1% |

| Filling Accuracy | Meet the requirements of Chinese Pharmacopoeia |

| Capping Pass Rate | ≥99.9% |

| Filling Heads | 12 heads |

| Machine Noise | ≤75dB |

| Bottle Outlet Temperature | ≤40°C (15°C above room temperature) |

| Power Consumption | From 0.5Kw to 35Kw, depending on the equipment |

| Air Pressure | 0-0.75Mpa |

| Air Consumption | 30-40m³/h (varies by equipment) |

| Water Consumption | 0.8-1m³/h (mainly for bottle washing machine) |

| Equipment Weight | From 150kg to 3000kg, depending on the equipment |

| Dimensions | From 1300×1100mm to 7000×2000mm, depending on the equipment |

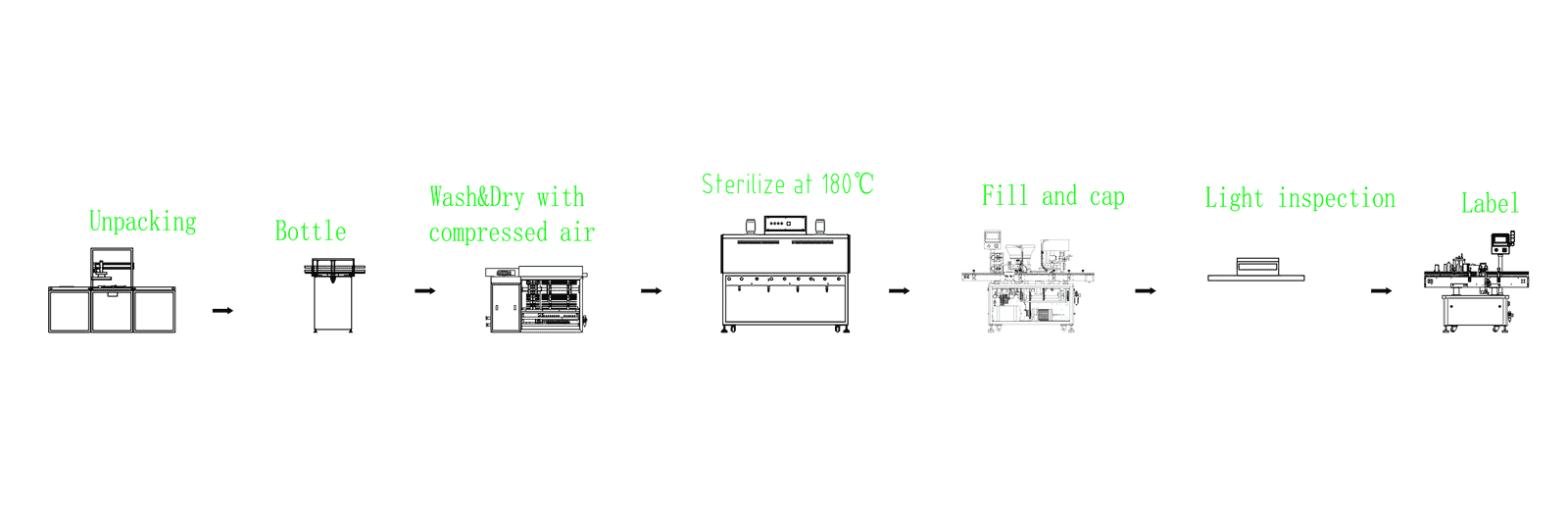

How Our Oral Liquid Filling Line Works?

Unpack → Bottle → Wash → Dry with compressed air → Sterilize at 180℃ → Fill and cap → Light inspection → Label

Technical Superiority of 50ml Filling Line

| Parameter | This Equipment | Industry Average |

|---|---|---|

| Production Speed | 12,000 bottles/hour | 8,000-10,000 bottles/hour |

| Bottle Breakage Rate | ≤0.1% | 0.3-0.5% |

| Sterilization Time | ≥6 minutes | 3-5 minutes |

It is an indispensable auxiliary machine for connecting equipment in the pharmaceutical industry. It plays a role in sorting and storing bottles in production. It is equipped with sensors and front and rear machines to form a Liquid Filling Line.

Oral liquid filling line

| Parameter | Specification |

|---|---|

| Bottle Specifications | For various bottle specifications, please confirm when ordering |

| Power Supply | Voltage: 220V; Frequency: 50Hz |

| Motor | Model: 5GN50KG; Power: 0.5 kW |

| Dimensions | Φ1200 × 1000 (unit: mm) |

The Automatic Bottle Washing Machine plays a vital role in the filling production line, especially in ensuring bottle hygiene and production efficiency.

It is usually located at the front end of the production line and is responsible for thoroughly cleaning and sterilizing the bottles to ensure that the product will not be contaminated during the filling process.

Automatic bottle washing machine

| Feature | Details |

|---|---|

| Machine Type | Clamp-type Automatic Bottle Washing Machine |

| Bottle Size | 50-1000 ml |

| Washing Capacity | 40-200 bottles per minute |

| Dimensions | 6000 × 1750 × 2000 mm |

| Performance | High-efficiency, robust performance |

| Instant Quote | Available on request |

Machine Details

Feeder