Rotary Tablet Compression Machine ZP-5/7/9D

The rotary tablet machines feature automatic rotation and continuous tablet pressing, efficiently transforming granular materials into tablets. The upgraded ZP series improves output density uniformity and minimizes tablet breakage.

The machine's fully enclosed exterior, made from durable stainless steel, prevents cross-contamination and complies with GMP standards.

Ideal for laboratories, small to medium-sized pharmaceutical factories, food manufacturers, health care industries, veterinary drug producers, and chemical industries.

Features

- Input Requirements: A high degree of dryness, maximum uniformity (within the range of 20 to 60 mesh), and great adhesion.

- Each machine is equipped with an overload protection device to stop the operation automatically when the pressure is overloaded.

- The rotary stamping forming station with multi-punching dies generates higher production efficiency than traditional single mold tablet pressing machines.

Specifications

| Weight(kg): | 960 |

| Filling Accuracy: | 1 (%) |

| Power: | 6Kw |

| Packing Volume: | 5 (L) |

| Subpackaging Capacity: | 1 (ml) |

| Applicable Industries: | Daily chemicals, medicine |

| Filling Apeed: | 10000 to 150000 |

| Packing Type: | Capsules,tablet |

Machine Details

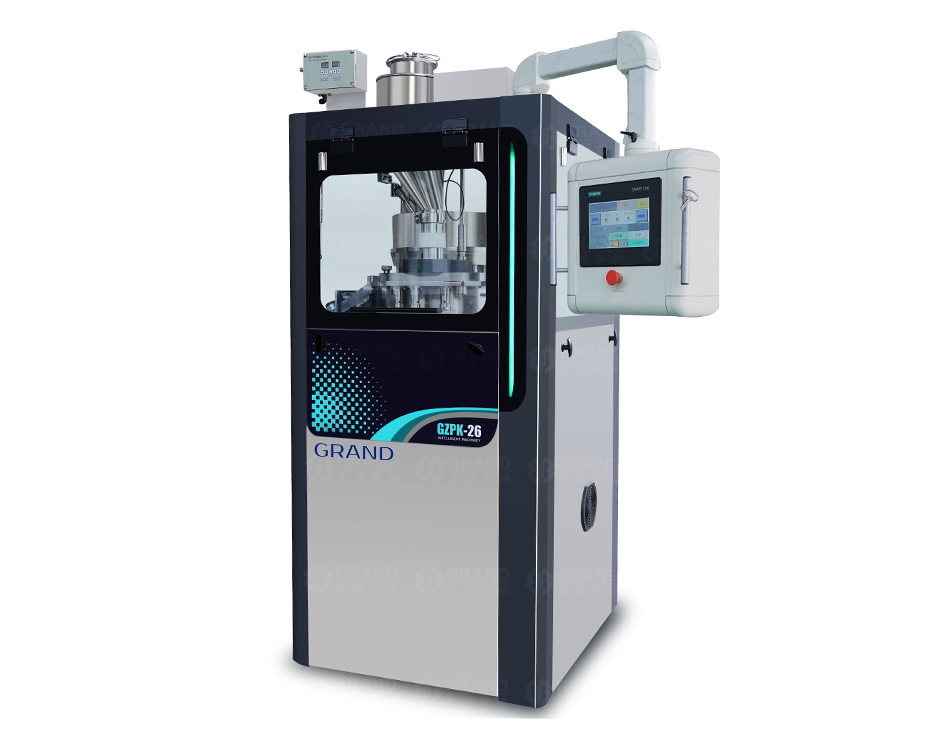

Tablet Press Head

Cylinder

Electrical Case

Stamping Forming Station

Control Pannel

Discharge Hopper

FAQS

Here are some FAQs

1After-sales service and warranty and the minimum order quantity?

Ten year warranty, lifetime after-sales service, with a minimum order quantity of one unit.

2What is the ideal moisture content for the raw materials?

The machine operates best with raw materials having a moisture content below 5%. This ensures optimal tablet formation and prevents issues during compression.

3Can this machine handle different granular sizes?

Yes, it is designed to handle granular sizes ranging from 20 to 60 mesh, offering flexibility in the production process.

4Is the machine suitable for small-scale production?

Absolutely, this machine is ideal for laboratory and small-scale pharmaceutical production, offering precise control and efficiency.

5How does the machine ensure tablet quality?

The machine requires raw materials to meet specific moisture and adhesion criteria, ensuring consistent and high-quality tablet production.

6What is the machine's filling speed range?

The filling speed ranges from 10,000 to 150,000 units per hour, allowing for flexible production based on your needs.

7What types of materials can be used with this machine?

The machine is suitable for dry powders with specific moisture content and adhesion properties, making it ideal for pharmaceuticals and daily chemicals.

8How precise is the filling accuracy of this machine?

The machine offers a filling accuracy of 1%, ensuring consistent and accurate dosage in each tablet.