Solid Preparation Granulation Line

Grand Solid Preparation Granulation Line is the most widely used tablet production system in pharmaceutical factories. This fully integrated production line is designed to deliver high efficiency, consistent quality, and fully automated packaging—all in compliance with GMP standards. From wet granulation to final cartoning, our system transforms raw powder into perfectly formed tablets ready for market.

Why Choose Our Solid Preparation Granulation Line?

- Fully Automated Process: Minimizes human error and contamination while reducing labor costs.

- GMP-Compliant: Every stage of production strictly adheres to global quality and safety standards.

- High Production Efficiency: Designed for rapid processing and consistent output.

- Versatile Packaging Options: Offers multiple packaging formats to suit diverse market needs.

- Customizable Integration: Can be tailored to meet your specific production requirements.

Solid Preparation Granulation Line Technical Parameters

| Equipment | Specifications |

|---|---|

| Wet Granulator | Tailored to handle various batch sizes |

| Dryer | Fluidized dryer designed for rapid boiling and moisture removal |

| Tablet Press | Produces tablets in multiple sizes and shapes for different formulations |

| Coating Machine | Capable of applying both thin film and sugar coatings |

| Packaging Formats | Options: aluminum-plastic, all-metal, metal-plastic-aluminum |

| Automation Level | Fully automated with PLC control, touchscreen interfaces, and intelligent sensor systems |

How Our Solid Preparation Granulation Line Works?

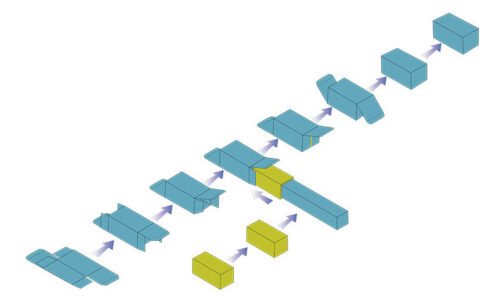

Process flow chart :

Powder Feeding & Wet Granulation → Fluidized Drying → Blending → Tablet Compression → Coating (Optional) → Packaging

Competitive Advantages

Compared to Industry Peers:

- Integration: Unlike many competitors, our system integrates every step—from granulation to final packaging—into a seamless, automated production line.

- Customization: Our production line is highly flexible, allowing for modifications to meet unique customer requirements.

- Quality Assurance: Our equipment strictly adheres to GMP standards, ensuring superior product quality and safety.

- Cost Efficiency: Reduced labor requirements and minimized production errors translate into significant cost savings over time.

- Environmental Sustainability: Our design minimizes waste and energy consumption, setting a benchmark for eco-friendly pharmaceutical production.

Wet Granulator

The Wet Granulator works by feeding material into the mixing granulation bin through an optional automatic vacuum feeder.

| Item | HLSG-600 |

|---|---|

| Hopper Volume | 400L |

| Stirring Feeding Volume | 150-480L |

| Stirring Power | 30KW |

| Granular Motor | 11KW |

| String Speed | 20-200rpm |

| Weight | 2600kg |

| Host Size (L×W×H) | 3200x1500x2800mm |

Fluid Bed Granulator

The Fluid Bed Granulator enhances powder granulation and reduces dust by integrating spraying, mixing, granulation, coating, and drying in a sealed, GMP-compliant system with flexible operation and easy maintenance.

| Item | FG-60 |

|---|---|

| Volume | 220L |

| Container Diameter | 1000mm |

| Capacity | 60kg |

| Steam Pressure | 0.4-0.6MPA |

| Steam Consumption | 120kg/h |

| Compressed Air Pressure | 0.4-0.6MPA |

| Compressed Air Consumption | 0.9m³/min |

| Air Blower | 11KW |

| Electric Heating Power | 30KW |

Powder Mixer Pharmaceutical FZH 500

The powder mixer is mainly used for mixing solid particles in the food industry.Featuring stable transmission and high-speed mixing.

| Item | Planetary Mixer |

|---|---|

| Weight | 500-5000KG |

| Power | 2.2 KW |

| Warranty Period | 5 years |

| Core Components | Motors, Gears, Pressure Vessels, Gearboxes, Pumps, PLCs, Bearings, Engines |

| Material | SUS304, SUS304L, SUS316, SUS316L |

| Application | Powder |

| Power Supply | 2.2-37KW |

| Cylinder Volume | 100L |

| Net Load | 100-5000 Kg |

Automatic Tablet Compression Machine GZPK-26

The GZPK series Automatic High Speed Rotary Tablet Press Machine is meticulously engineered for the precise and efficient manufacturing of tablets, with a maximum production capacity of 160,000 tablets per hour.

| Item | GZPK-26 Tablet Press |

|---|---|

| No. of Stations | 26 |

| Capacity (tablets/h) | 30,000-160,000 |

| Rotation Speed | 11-102 rps/min |

| Max Tablet Diameter | Ф25mm |

| Main Pressure | 100KN |

| Pre-pressure | 20KN |

| Max. Filling Depth | 20mm |

| Diameter of Die | 38.1mm |

| Length of Punch | 133.6mm |

| Main Motor Power | 11KW |

| Dimensions (L×W×H) | 800(+440)×890(+440)×1945mm |

| Net Weight | 1400 KG |

Pharmaceutical Tablet Coating Machine Combination

This Pharmaceutical Tablet Coating Machine Combination is mainly used for applying various protective and functional coatings to tablets, pills, and candies across pharmaceutical, food, and biotech industries.

| Item | GRAND-B-150E |

|---|---|

| Max. Capacity | 150L / time |

| Coating Pan Diameter | Φ1200mm |

| Coating Pan Speed | 0-16 r.p.m |

| Main Machine Power | 2.2 kW |

| Exhaust Cabinet Air Flow | 7419 m³/h |

| Hot Air Temperature Range | ~80℃ |

| Main Machine Dimensions (L×W×H) | 1730×1320×2030 mm |

| Main Machine Weight | 850 kg |

| Purified Air Pressure | 0.4 MPa |

| Steam Consumption | 80 kg/h |

| Electric Heating Power | Three-phase, five-line 38 kW |

Automatic Alu Blister Packing Machine DPP-180L

The Automatic Blister Packing Machine is engineered for utilization in the pharmaceutical and candy industries. It effectively packages products such as tablets, pills, candies, and capsules, guaranteeing precise and reliable blister packaging for a diverse range of products.

| Parameter | Value |

|---|---|

| Punching Efficiency | 20-180 plates/min (aluminum-plastic) |

| Capacity (tablets/h) | 18,000-236,000 plates/hour |

| Maximum Forming Area | 130×250mm |

| Aluminum-Plastic Depth | 12mm-14mm |

| Adjustable Stroke Range | 40~130mm standard machine |

| Standard Plate Size | 80×57mm |

| PVC and PTP Width and Thickness | PVC:270×0.15~0.45mm, PTP:270×0.02~0.03mm |

| Duraluminum | 260 |

| Power Supply and Power | 380V 50HZ 7.5Kw |

| Main Motor Power | 2.2Kw |

| Gas Requirement | ≥0.3m3/min |

| Size | 3600×720×1650mm |

| Weight | 1700kg |

Automatic Cartoning Machine GZ-120

Automatic Cartoning Machine GZ-120 handle 30-100 cartons per minute, support 250-350 g/m² carton weight, and offer flexible leaflet sizes and folding options for versatility.

All in One Automatic Case Packer Machine GZ-600

The GZ-600 boosts efficiency by automating tasks such as unpacking, placing box pads, packing, inserting packing lists, and sealing. It significantly increases productivity across various packaging processes.

The machine includes a data transmission interface to record and export key data. It also provides safety alerts for issues like unpacking errors, missing boxes, low compressed air pressure, and tape shortages.

FAQs About Solid Preparation Granulation Line

Contact Us