Grand Ternary Screening Machine

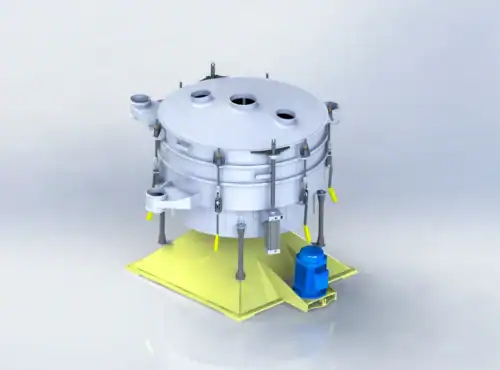

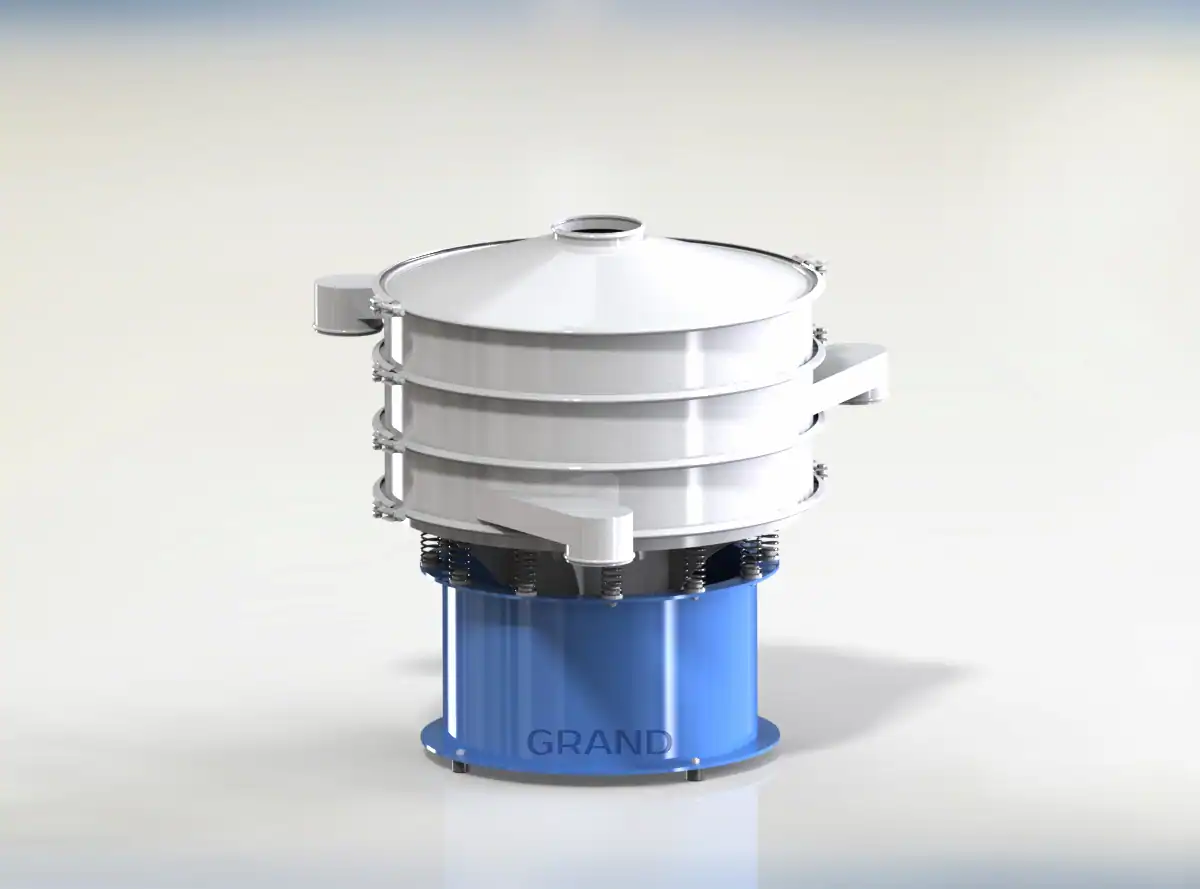

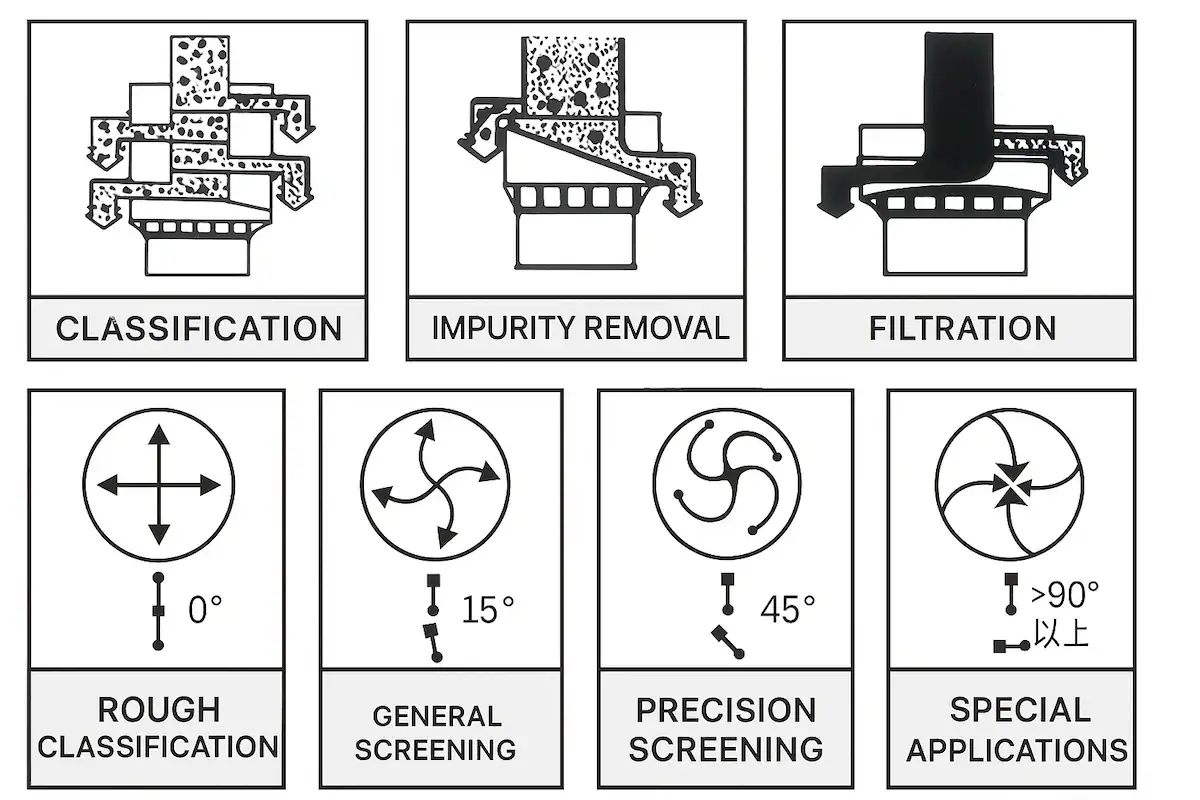

The Grand Ternary Screening Machine is a precision-engineered industrial screening machine designed for high-performance material separation. It delivers three-dimensional, multi-axis motion—combining horizontal, vertical, and inclined vibration—to sift powders, granules, and slurries with exceptional accuracy. Built with durable stainless-steel construction and heavy-duty springs, this rotary vibrating screen is ideal for heavy industrial use. Its robust design ensures long service life and stable operation under continuous production, even in harsh environments. The result is finer particle sorting and higher throughput than conventional screens, making it a valuable asset for international manufacturing and processing plants.

Develop Your Business with Grand

Get a Quote Today!

Applications

- The Grand Ternary Screening Machine is suited to a wide range of industries and materials. Common applications include:

- Food & Beverage: Sorting flour, starches, spices, and other fine powders.

- Pharmaceuticals: Precision sieving of active ingredients and excipients.

- Chemicals: Classifying particles in paints, pigments, resins, and polymers.

- Metals & Mining: Screening ore, sand, gravel, and recycled metals.

- Agriculture & Fertilizer: Grading compost, fertilizers, and animal feed.

- Building Materials: Sifting cement, lime, and abrasives for manufacturing.

These “industrial screening machines” are favored in sectors where high purity and consistency matter. They handle sticky or wet materials without clogging, thanks to self-cleaning features. Global corporations rely on our screening equipment to improve product quality and reduce downtime.

Technical Specifications

| Model | XF-400 | XF-600 | XF-800 | XF-1000 | XF-1200 | XF-1500 |

|---|---|---|---|---|---|---|

| Screening Diameter (mm) | φ360 | φ560 | φ760 | φ950 | φ1150 | φ1450 |

| Screening Area (m²) | 0.1 | 0.25 | 0.45 | 0.71 | 1.05 | 1.6 |

| Mesh Size | 2–500 mesh | 2–500 mesh | 2–500 mesh | 2–500 mesh | 2–500 mesh | 2–500 mesh |

| Layers | 1–3 | 1–3 | 1–3 | 1–3 | 1–3 | 1–3 |

| Motor Power (kW) | 0.18 | 0.25 | 0.55 | 0.75 | 1.1 | 1.5 |

Key Features

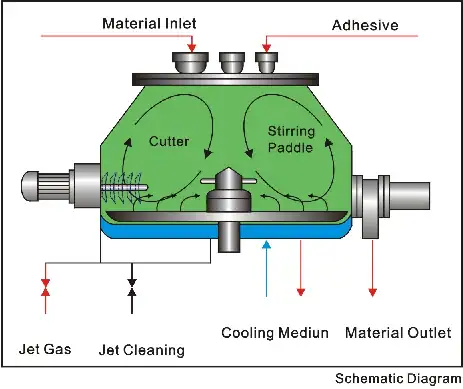

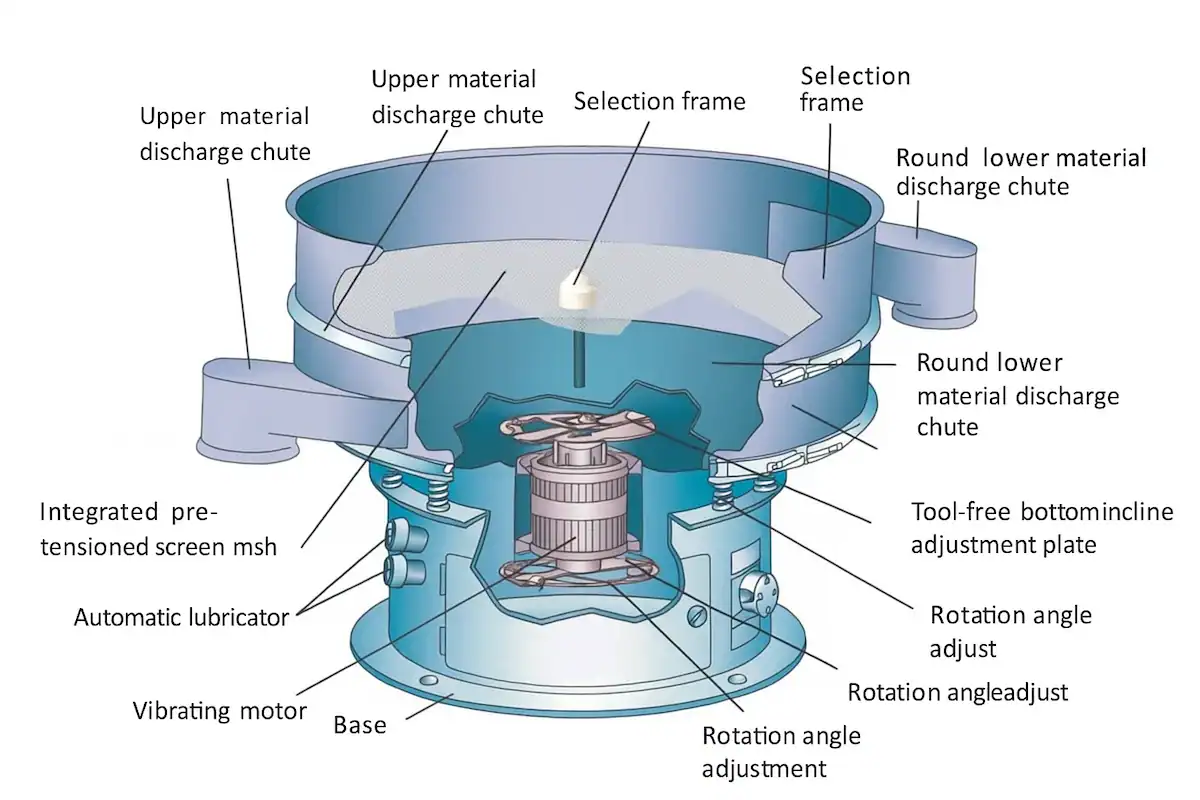

Triple-Axis Vibration: Provides a unique rotating motion that uniformly distributes material across the screen. This “rotary screen” mechanism means longer effective travel paths for particles and finer separation.

High Screening Efficiency: A self-cleaning design prevents blockage by sticky or wet material, ensuring continuous operation. This leads to up to 95% screening accuracy in many applications.

Durable Construction: Contact parts are made of 304 stainless steel (with optional 316L), resisting corrosion and abrasion. The heavy-duty frame and springs absorb vibration shock, resulting in reliable, long-lasting performance.

Adjustable Amplitude: By changing the angle or weight of eccentric blocks on the motor, operators can fine-tune the vibration intensity. This flexibility lets users optimize throughput and selectivity for different materials.

Multi-layer Screening: Supports 1 to 5 screen decks, allowing simultaneous classification into several grades. Typical screen sizes range from 2 mesh up to 500 mesh (0.025–100 mm) to meet varied fineness requirements.

Low Noise & Dust Control: The sealed housing and optional dust shroud keep the work environment clean and quiet. When equipped, the enclosure reduces noise levels below 80 dB and contains dust for safety and regulatory compliance.

Easy Maintenance: Quick-release clamps and modular design enable rapid mesh changes without tools. Built-in cleaning attachments (rubber balls or optional ultrasonic device) help prevent clogging and extend screen life.

Our screening machines consistently deliver large processing capacity with stable operation. They combine the fine separation capability of vibrating screens with the gentle rotary motion of gyratory screens to protect delicate materials and improve yield.

Why Choose Grand Swing Screens?

Proven Expertise: Grand has decades of experience crafting industrial screening machines. Our engineering team specializes in vibratory equipment, and we continually innovate with patent-pending designs (e.g. flow-directing screen rings) to stay ahead in the industry.

Built for Precision & Durability: Each screening machine is rigorously tested for accuracy and longevity. Our premium components – from ABB or Siemens motors to SKF/NSK bearings – ensure consistency in performance. A robust, one-piece welded drum and sealed assembly prevent wear and tear, delivering up to 5× longer mesh life than standard screens.

Global Support: With exports to over 30 countries, Grand provides worldwide service and spare parts availability. We offer 24/7 technical support and even onsite training. A comprehensive Screening Machine User Tutorial and multilingual manuals come standard with every machine. Local distributors ensure quick response for maintenance and parts replacement.