Exploring the Versatility of Gummy Candy Production Lines: What Products Can They Produce?

Top 8 pharmaceutical packaging line manufacturers in the world-GRAND

Exploring China’s Premier Pharmaceutical Machinery Factory–Grand

In the field of Pharmaceutical Machinery Manufacturing, Grand Machinery has long been recognized for its outstanding technology and efficient production management. As someone passionate about automation production lines and mechanical equipment, visiting Grand’s Pharmaceutical Machinery Manufacturing workshop was an invaluable experience. This article will share my insights into this visit, highlighting the company’s production capabilities and its key role in the Pharmaceutical Machinery Manufacturer industry.

Overview of Grand Machinery Factory

Founded in 2006, Grand Machinery has become a leader in the Pharmaceutical Machinery Manufacturing industry, thanks to its continuous technological advancements and innovations.

The fields involved include personalized customization of various workshops in the pharmaceutical, food, health care products and other industries

Located in Guangzhou, the factory spans a vast area and is equipped with modern production facilities and precision manufacturing processes. Every machine and step in production reflects Grand’s commitment to quality and efficiency, which has solidified its reputation as a top Pharmaceutical Machinery Manufacturer.

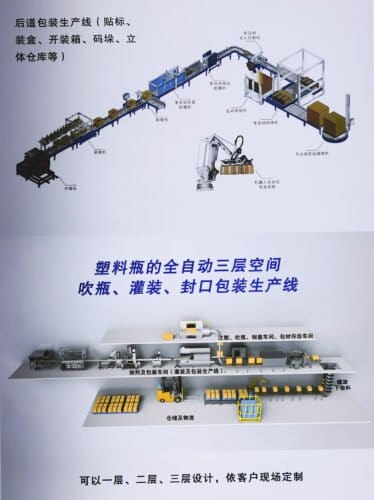

Fully automatic three-layer space for plastic bottles Blowing, filling and sealing packaging production line

Entering the Production Workshop

Upon entering the Grand production workshop, the first thing that stands out is the efficient production lines and the well-organized work environment. The factory is divided into multiple areas, each dedicated to a specific task in Pharmaceutical Machinery Manufacturing, and equipped with advanced automation systems.

Mixing machine waiting to be shipped out

With skilled workers and seamless coordination between mechanical devices and manual operations, the production flow is smooth and efficient. This level of efficiency is what makes Grand a recognized leader in Pharmaceutical Machinery Manufacturing.

On-site acceptance of High efficiency wet mixing granulator

We began our tour in the assembly area, where technicians were assembling various precision parts for pharmaceutical machinery.

Tablet Press Components

The process relies on precise coordination between machines and skilled workers. This meticulous approach is a core reason why Grand maintains such high-quality standards in pharmaceutical machinery production.

The boss is checking the equipment with the technicians on site

Next, we moved to the welding area, where high-temperature welding equipment was used to fuse metal parts for pharmaceutical machinery. The process requires technical expertise and precision, ensuring that every product undergoes rigorous quality checks after welding.

Tablet press core components explained

In the machining area, large CNC machines were performing precision operations on parts for pharmaceutical machinery. These advanced machines enable Grand to achieve highly efficient and precise production, ensuring the quality of every component used in pharmaceutical equipment.

Replaceable tablet press punches

Automation and Intelligent Integration in Pharmaceutical Machinery Manufacturing

Grand Machinery is at the forefront of intelligent production in the Pharmaceutical Machinery Manufacturing sector. The workshop is filled with automated machines that not only perform tasks efficiently but also monitor production in real-time and adjust parameters to improve accuracy.

Grand production workshop

This level of automation is vital for maintaining high standards in pharmaceutical machinery production.

Commitment to Quality Control

Quality management is the heart of Grand’s Pharmaceutical Machinery Manufacturing process. The company implements a strict quality control system at every stage, from raw material inspection to final product testing. Advanced inspection equipment and quality inspectors are present at every production line, ensuring that every piece of pharmaceutical machinery meets international standards.

View Pouch Packaging Showroom

During my visit, I had the opportunity to tour the quality inspection center, where technicians conducted rigorous tests on pharmaceutical machinery. These included strength tests, durability tests, and performance efficiency tests, all of which were recorded to ensure that every product leaving the factory performs excellently in real-world applications.

Customizable molds

From Production to R&D: Innovation in Pharmaceutical Machinery

In addition to production, Grand Machinery places significant emphasis on research and development in pharmaceutical machinery. The company’s R&D center is home to top industry talent that continuously works on optimizing existing equipment and developing new, smarter products. These efforts aim to meet the growing demand for energy-efficient, environmentally friendly, and highly efficient machinery in the pharmaceutical machinery manufacturing sector.

During my visit, I had the privilege of touring the R&D lab, where engineers were focused on the development of next-generation pharmaceutical machinery that promises to revolutionize production lines in the pharmaceutical industry.