High Shear Mixer Granulator HLSG-10: Precision Wet Granulation

Types of Soft Capsules & Production Line

When is Soft Double Aluminum Packaging the Right Choice for Medicine Packaging?

Category: Pharmaceutical Manufacturing | Reading Time: 11 mins

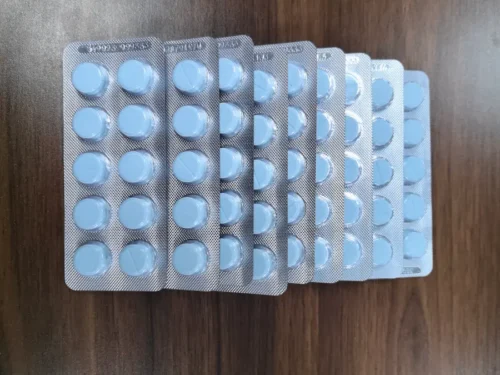

In the competitive world of pharmaceutical manufacturing, the final barrier between a potent drug and environmental degradation is medicine packaging. While rigid PVC blisters are common, they are not a universal solution. For sensitive formulations, Soft Double Aluminum Packaging (often referred to as Strip Packaging) is frequently the superior choice.

But how do you know if this format is right for your production line? And what differentiates the machinery available on the market today?

In this guide, we explore the specific use cases for soft double aluminum, analyze the upstream manufacturing context, and take a technical deep dive into the NSL-350, a machine designed to solve modern packaging challenges.

The "Gold Standard" for Sensitive Formulations

Soft double aluminum packaging involves sealing tablets or capsules between two layers of soft aluminum foil. Unlike standard blisters where one side is plastic (PVC/PVDC), this method uses aluminum on both sides.

1. When Light and Moisture are the Enemy

The primary reason manufacturers switch to soft double aluminum is protection. If your formulation is hygroscopic (absorbs moisture from the air) or photosensitive (degrades in light), plastic blisters often fail. The NSL-350 is specifically designed to achieve "good sealing and light avoidance," which significantly "extends the shelf life of the product". This makes it the ideal choice for:

Antibiotics and Probiotics: Highly sensitive to moisture.

Vitamin C and Effervescent Tablets: Extremely susceptible to oxidation and humidity.

2. When Portability and Dosage Convenience Matter

Soft double aluminum strips are flexible and lightweight. They are easy for patients to carry without the bulk of rigid blister cards. The packaging is "easy to carry", improving patient adherence—a critical metric for pharmaceutical companies.

3. Beyond Pharma

Interestingly, this packaging format isn't limited to drugs. The NSL-350 is capable of packaging "various similar tablet-shaped electronic components" in the electronics industry. This applies to coin batteries, small capacitors, or sensitive memory chips that require shielding from static and environmental moisture.

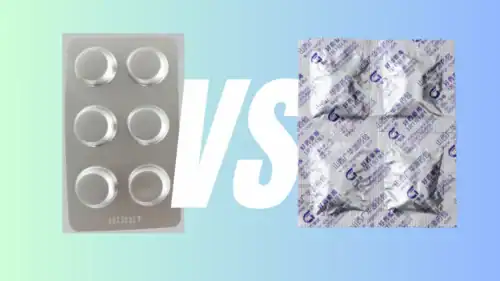

Market Landscape: Types of Aluminum Packaging

When sourcing medicine packaging equipment, buyers often encounter confusion between "Cold Form Blister" (Alu/Alu) and "Soft Double Aluminum" (Strip).

Cold Form Blister (Alu/Alu): This uses a stamping process to create a cavity in a hard aluminum sheet. It offers great protection but consumes more material and results in a larger pack size.

Soft Double Aluminum (Strip Packing): This uses two flexible foils that sandwich the product. It is generally more material-efficient and compact.

The NSL-350 falls into the latter category but introduces modern "PLC touch screen control systems" to modernize what was traditionally a purely mechanical process.

Spotlight on the NSL-350: A Technical Review

If you have determined that soft double aluminum is the right format for your product, the next step is selecting the machine. The Grandpack NSL-350 represents the new generation of this technology.

1. Precision Control and Automation

Older strip packers relied heavily on mechanical gears that were difficult to adjust. The NSL-350 utilizes a Siemens PLC (Model 6ES7 288-1ST30-0AA0) and a Siemens Smart 700 HMI.

Benefit: You can "freely set and adjust the number of punched sheets on the touch screen" without the hassle of "frequently changing multiple gears and cams". This dramatically reduces changeover time between different product batches.

2. Temperature Stability (The Critical Factor)

NSL-350 Soft Double Aluminum Packaging

In heat sealing, temperature fluctuation leads to leaking seals. The NSL-350 employs a sophisticated temperature control architecture:

It uses a "temperature module" (Siemens 6ES7 288-3AT04-0AA0) rather than a simple on/off thermostat.

It is equipped with "advanced K-type temperature probes" (Model WRKM 301).

Result: This ensures the "surface temperature of the heat-sealing roller mold is stable and reliable," guaranteeing the airtightness of the medicine packaging.

3. Smart Feeding System

The machine features a "vibrating alignment feeding mechanism" equipped with "photoelectric monitoring devices". This automatically controls the flow of tablets.

Why this matters: It prevents the machine from running empty or jamming, ensuring that the "feeding, discharging, heat sealing, cutting, batch numbering, and punching" processes are fully automated.

4. Build Quality and Compliance

For GMP compliance, the "equipment shell is welded from 304# stainless steel," which is both beautiful and practical for cleaning. The internal electrical components read like a "Who's Who" of top-tier industrial brands:

Circuit Breakers: Schneider.

Relays: IDEC (Japan).

Encoders: Omron.

Solenoid Valves: AirTAC (Taiwan).

Frequency Converter: Siemens.

Using global standard parts like the Siemens 6SL3210 inverter ensures that maintenance and spare parts sourcing are easy for international buyers.

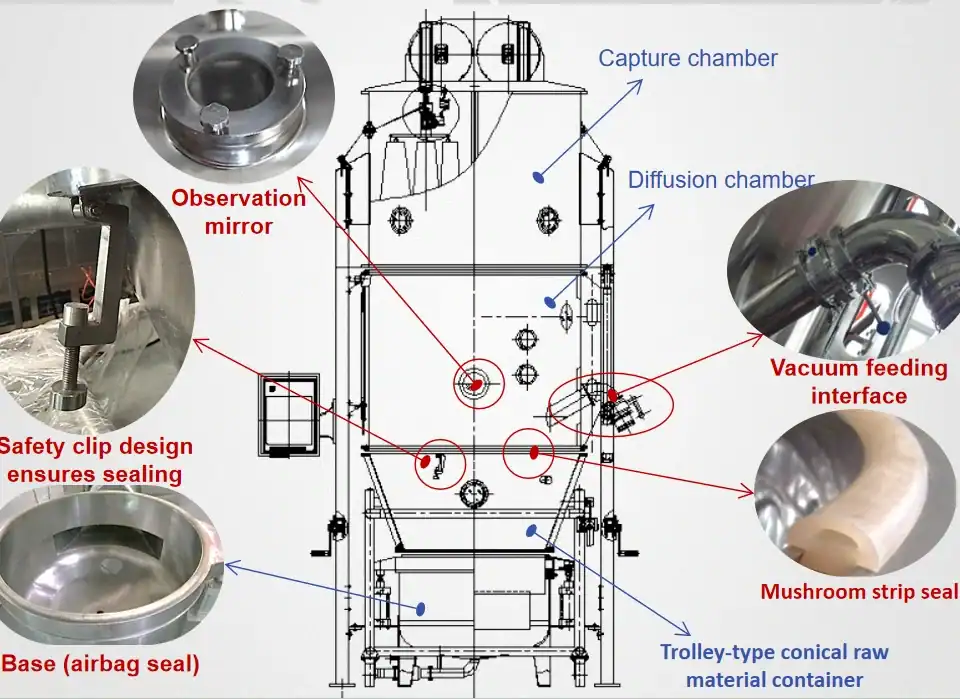

The Upstream Ecosystem: From Powder to Package

A common question from buyers setting up a new facility is: Where does this machine fit in the production line?

The NSL-350 sits at the very end of the solid dosage manufacturing chain.

Granulation: Powder is mixed and processed (e.g., using a High Shear Mixer).

Compression/Encapsulation: The granules are pressed into tablets or filled into capsules.

Dedusting/Polishing: Loose powder is removed.

Packaging (The NSL-350): The clean tablets/capsules enter the hopper.

Can this form a continuous line?

Yes. The NSL-350 is designed for high efficiency and automation. Because it uses a vibrating feeder with optical monitoring, it can be integrated with upstream tablet presses or capsule fillers via bucket elevators or vacuum conveyors. The machine monitors the material level; if the upstream supply slows down, the photoelectric sensors can signal the system to pause or adjust speed via the variable frequency drive.

Why Choose the NSL-350? (Summary of Advantages)

For buyers comparing options, the NSL-350 offers a specific set of operational advantages derived from its technical configuration:

Flexibility: It handles "various tablets and capsules" in the pharma industry and "electronic components" in the tech sector.

Efficiency: It operates at a punching frequency of "10~60 times/minute," allowing for high-speed production.

Quality Assurance: Optional features include "fiber optic detection for missing grains and waste rejection," ensuring no empty packages reach the customer.

Conclusion

Choosing medicine packaging is a balance between protection, cost, and patient convenience. Soft double aluminum packaging remains the superior choice for maximizing the shelf life of sensitive drugs.

The NSL-350 represents a mature, digitized solution to this packaging format. By moving away from mechanical complexity and embracing Siemens PLC automation and top-tier component reliability (Schneider, Omron, AirTAC), Grandpack offers a machine that is as reliable as it is efficient.

Ready to protect your product? Ensure your sensitive formulations get the shelf-life they deserve. Contact Grandpack today to discuss how the NSL-350 can integrate into your current pharmaceutical line.