How Automatic Cosmetics Filling Machine Streamline Skincare Packaging?

Blister Type: What Can the Grand Blister Machine Produce?

What Makes Supercritical Fluid Extraction a Game-Changer in Pharmaceutics?

What Makes Supercritical Fluid Extraction a Game-Changer in Pharmaceutics?

In recent years, pharmaceutical journals like the International Journal of Pharmaceutics have spotlighted Supercritical Fluid Extraction (SFE) as a cutting-edge method for isolating bioactive compounds from natural sources. A notable case study characterized supercritical CO₂[1]extracts of the medicinal mushroom Cordyceps sinensis, optimizing parameters (350 bar, 60 °C, 0.4 L/h CO₂ flow) to yield high-purity cordycepin and flavonoids—key markers for anti-inflammatory and energy-enhancing effects.

CO2 High Pressure Pump

How Does Supercritical CO₂ Improve Traditional Extraction?

Enhanced Solubility & Selectivity: Under supercritical conditions (T > 31.1 °C, P > 72.8 bar), CO₂’s density approaches that of a liquid while retaining gas-like diffusivity. This duality combines the best of distillation and liquid–liquid extraction, enabling up to hundreds-fold increases in solubility compared to ambient conditions[2].

Mild Operating Temperatures: Since supercritical CO₂’s critical temperature is just 31.1 °C, thermo-labile constituents—such as triterpenoids in reishi—remain intact, unlike high-heat Soxhlet or decoction methods that risk degradation.

Solvent-Free & Green: CO₂ is nontoxic, nonflammable, and recyclable. After extraction, depressurization yields pure extracts with zero solvent residues, simplifying downstream purification and ensuring compliance with stringent pharmaceutical regulations.

GDC-420 CO₂ supercritical extraction machine

Why Is Chemical Extraction Efficiency Critical for Mushroom Compounds?

Mushrooms like scalloped hedgehog (Sarcodon imbricatus) and reishi (Ganoderma lucidum) harbor lipophilic bioactives—ergosterol, phenolics, and terpenoids—that underpin their immunomodulatory and antioxidant activities. Efficient Chemical Extraction via SFE maximizes yield, purity, and repeatability, essentials for nutraceutical formulations and standardized medicinal products.

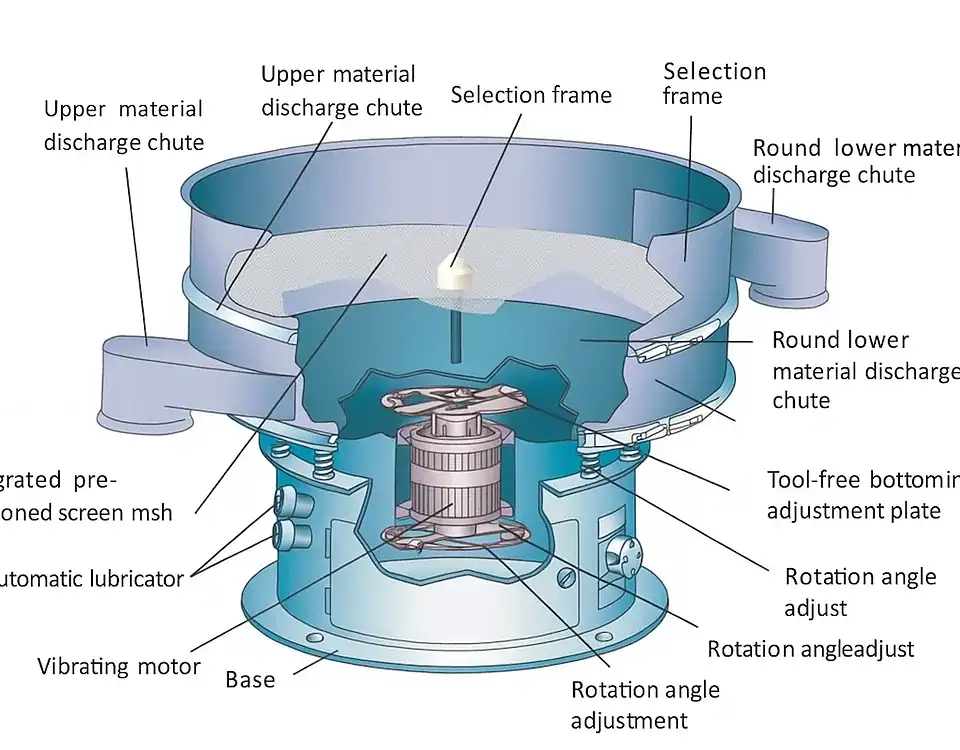

What Advantages Does the Grand Supercritical Extraction Machine GDC-420 Offer?

Replacing the legacy HA420-40-120-C model, the GDC-420 from Grand Supercritical Extraction Machine Series delivers:

Optimized Capacity: Four extraction vessels (29 L each) and two separators (20 L & 10 L) for simultaneous batch processing, boosting throughput by ~30% over predecessor designs .

Superior CO₂ Handling: An 800 L/h ceramic-plunger high-pressure CO₂ pump with variable frequency drive ensures stable flow at pressures up to 40 MPa, paired with a 45 kW cooling unit for precise temperature control down to –5 °C.

Automated Control & Safety: Advanced PLC touchscreen system monitors and logs temperature, pressure, and flow in real time; integrated safety valves and R485-linked sensors maintain operational integrity.

Energy & Cost Savings: Modular CO₂ recovery recycles residual gas to 1 MPa, cutting CO₂ consumption by up to 25%, while the quick-open clamp design reduces vessel turnaround time.

What Are the Tangible Benefits of Adopting SFE Technology?

The shift towards SFE isn't just about adopting a novel technology; it's about unlocking tangible benefits that can transform product quality and operational efficiency:

- Purity That Speaks Volumes: SFE delivers exceptionally pure extracts, free from the potentially harmful solvent residues often associated with conventional methods. This is paramount for pharmaceuticals, nutraceuticals, and food products where consumer safety and product integrity are non-negotiable.

- Preserve the Precious: The gentle, low-temperature conditions of Supercritical CO2 extraction make it ideal for processing thermally labile (heat-sensitive) and volatile compounds. This ensures that delicate essential oils, natural flavors, and bioactive molecules retain their potency, aroma, and therapeutic value. The precise temperature control systems in SFE machines, often using water jacket heating adjustable from room temperature to 80°C, are crucial for this preservation.

- Boost Your Yields: Due to the enhanced mass transfer properties of supercritical fluids—their ability to penetrate materials quickly and dissolve compounds efficiently—SFE often achieves higher extraction efficiency and greater yields compared to traditional techniques.

- Go Green, Save Green: SFE significantly reduces environmental impact by eliminating the need for hazardous organic solvents. It typically involves lower energy consumption compared to processes that require extensive solvent evaporation and recovery. The inherent recyclability of CO2 within the system further cuts down on operational costs and greenhouse gas emissions.

- Unlock New Product Frontiers: The remarkable selectivity of SFE can enable the isolation of novel compounds or specific fractions from raw materials that might possess unique properties. This opens doors for research and development, potentially leading to innovative products with enhanced characteristics or new market applications.

These advantages ripple through the entire value chain. Higher purity can simplify downstream purification, saving time and resources. Better preservation of active components leads to more efficacious or authentic end-products. The absence of residues simplifies regulatory compliance, particularly in food and pharmaceutical sectors, and strongly supports the "clean label" trend demanded by consumers.

How to Optimize Your CO₂ Supercritical Extraction Machine?

Define Target Compounds: Select operating window based on solute volatility and polarity. Nonpolar terpenoids extract efficiently at 200–300 bar and 40–50 °C, whereas flavonoids may require entrainers like 1–5% ethanol to alter polarity.

Adjust Density via P–T Tuning: Minor pressure tweaks (±10 bar) can dramatically shift CO₂ density—and thus solvation power—enabling fine-tuned selectivity without retooling hardware.

Leverage Modular Vessels: Use multiple smaller extraction vessels in parallel to test conditions rapidly before scaling to larger batches, reducing trial-and-error cycles.

Automate Depressurization: Employ isothermal decompression to separate extract from CO₂ smoothly, preserving volatile aromatics and ensuring complete CO₂ recovery.

Why Choose Grand’s GDC-420 for Your Next Project?

Whether you’re developing a reishi-based supplement or isolating ergosterol from scalloped hedgehog, the GDC-420 CO₂ supercritical extraction machine unites high-throughput capacity, green credentials, and precise process control. By harnessing Supercritical Fluid Extraction, you unlock superior yields, product consistency, and regulatory compliance—all essential for modern pharmaceutical and nutraceutical innovation.

References

[1].Supercritical Carbon Dioxide Extracts of Cordyceps sinensis: Chromatography-based Metabolite Profiling and Protective Efficacy Against Hypobaric Hypoxia.

[2].Krivošija, S.; Nastić, N.; Karadžić Banjac, M.; Kovačević, S.; Podunavac-Kuzmanović, S.; Vidović, S. Supercritical Extraction and Compound Profiling of Diverse Edible Mushroom Species. Foods 2025, 14, 107. https://doi.org/10.3390/foods14010107