Tablet Counter Guide (2025): Pharmacy & Industrial Machines

What is Enteric Coating? — Benefits, Uses & Coating Equipment

Grand Ternary vs Circular Swing Screening Machines – Comparison & Guide

The choice of an industrial screening machine can dramatically impact productivity and product quality in sectors like food, pharmaceuticals, chemicals, and metallurgy.

Grand’s two flagship models – the Ternary Screening Machine (tri-dimensional vibratory screen) and the Circular Swing Screen (YBS series) – each offer unique advantages. In this article, we’ll dissect their design, performance, and applications to help industrial buyers choose the right solution. The comparison covers features, applications, and quantitative specs in both text and tabular form, using Grand’s own documentation for accuracy.

Grand’s Ternary Screening Machine (XF Series)

Figure1: Grand’s Ternary (tri-dimensional vibratory) Screening Machine schematic showing the motor, eccentric weights, screen deck, and adjustment features.

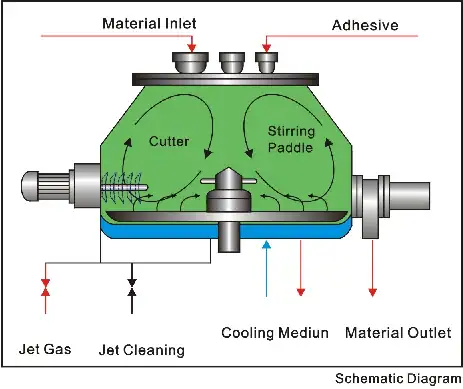

The Grand Ternary Screening Machine (XF series) is a compact vibrating screen that uses an upright motor with eccentric weights on both ends. The motor’s rotation is converted into a complex horizontal, vertical and inclined tri-dimensional motion. This causes material on the screen to move in an outward spiral (gradually expanding from the center) across the screen surface. The long spiral trajectory increases material travel path and screen utilization, enabling fine and probabilistic sieving of powders and granules. In practice, this design yields high precision separation and effective screening, especially for materials requiring thorough fines removal.

Key Specifications (Ternary XF series): According to Grand’s product sheet, the XF models cover diameters from 340 mm (XF-400) up to 1400 mm (XF-1500). Correspondingly, their single-deck screening areas range from about 0.09 m² up to 1.5 m². The screens support mesh sizes from 2 to 500 mesh (up to very fine powders) and can be configured in 1 to 5 layers for multi-fraction sieving. Motor power ranges from just 0.18 kW on the smallest model to about 1.5 kW on the largest (XF-1500). This relatively low power reflects the machine’s efficient use of mechanical motion.

Design & Operation: Grand’s manual notes that the eccentric block angles (and mass) on the vibratory motor can be adjusted to change the horizontal and vertical amplitudes. This means operators can tune the machine to handle different materials or desired flow rates by redistributing eccentric weights – an aspect we’ll touch on in our Screening Machine User Tutorial section below. The ternary machine’s spring-mounted base and enclosed design reduce transmitted vibration to the floor (helpful in noise-sensitive environments), and it meets the same industrial safety and cleaning standards as Grand’s other units. The unit can be fitted with quick-release clamps for easy screen mesh changes, and optional features like automatic lubricators or adjustable discharge chutes.

Performance: The XF series excels at fine mesh screening. Grand states it can effectively screen powders below 200 mesh, and even slurries up to 500 mesh. This makes it ideal for pharmaceutical, chemical or food-grade powder classification where precision is critical. Although exact throughput depends on material properties and mesh size, the Ternary Screening Machine’s long travel path and concentrated energy mean high efficiency per unit area, suitable for smaller batch or fine-tuning applications. In general, smaller footprint models (XF-400/600) are used for laboratory or pilot-scale screening, while larger models (XF-1200/1500) are capable of handling industrial batch sizes with screening areas ~1 m².

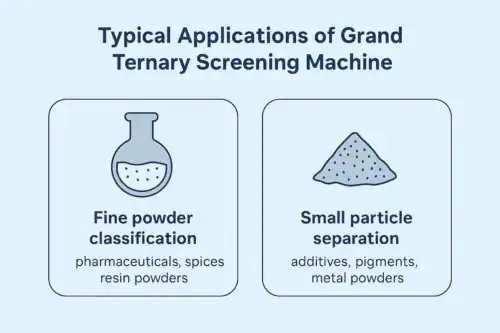

Applications: Typical uses for Grand’s Ternary Screening Machine include:

Fine powder classification: e.g. pharmaceuticals, spices, resin powders.

Small-particle separation: additives, pigments, metal powders (fine fractions).

Liquid-slurry screening: with fine meshes (up to 500 mesh).

Because of its delicate, triple-axis motion, it can handle sticky or delicate materials better than a high-G linear screen. However, it is generally suited for dry powders or pastes; it is not designed for bulk granular flow or washing operations. Industries using this machine include food (flour, sugar, spices), pharmaceuticals, specialty chemicals, metallurgy (fine abrasives), and plastic or ceramic powders.

Advantages of the Ternary Screening Machine: Key benefits of Grand’s XF series include:

Precision sieving: Three-dimensional motion yields very thorough screening.

Fine mesh capability: Handles very fine 2–500 mesh (granule to fine powder).

Compact design: Smaller footprint for lab or pilot use, yet scalable with multiple decks.

Adjustable amplitudes: Eccentric weights allow on-the-fly adjustment of vibration strength.

Low power consumption: As low as 0.18 kW for small models.

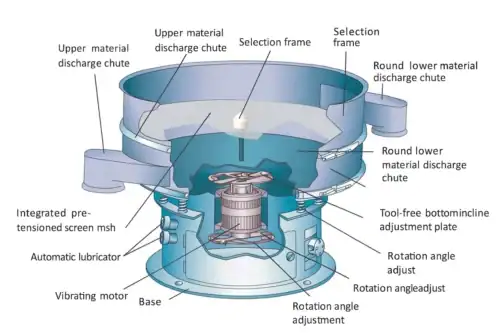

Grand’s Circular Swing Screen (YBS Series)

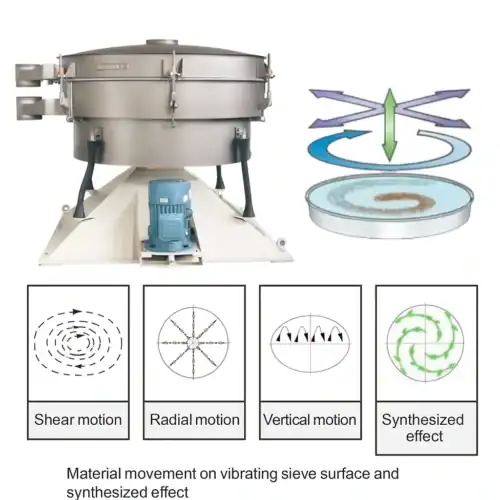

Figure2: Material motion on Grand’s Circular Swing Screen (YBS series) – combining planar circular shaking with vertical tossing creates a spiral roll of material for uniform screening.

The YBS Circular Swing Screen by Grand is a low-frequency rotary-vibrating screening machine that simulates a manual shaking action. It superimposes a planar circular motion with a gentle upward tossing of material, producing a “non-linear 3D rolling” effect on the screen surface. In practice, particles move outward in an spiral trajectory (much like the ternary screen) but at a lower vibration frequency (swing motion) for large-scale separation. This design is particularly effective at preventing mesh clogging: materials are gently lifted and thrown rather than hammered.

Key Specifications (YBS series): Grand’s YBS Swing Screens come in larger sizes. Models range from YBS-600 (600 mm diameter, ~0.29 m² area) up to YBS-2200 (2200 mm diameter, ~3.8 m² area). Some vendors’ data even list a YBS-2600 (~5.3 m²) for extremely high throughput (see Appendix). All YBS models offer up to 5 layers of screening (typically 5 decks).

Motor power scales accordingly: a YBS-600 uses about 0.25 kW, whereas the large YBS-2000/2200 machines use 2.2–5.5 kW (some models use dual motors, e.g. “2.2/4 kW” for the 1600/2000 mm units). For example, YBS-1200 is 1.5 kW and YBS-2000 is 4 kW. The screens use common mesh sizes (e.g. 10–200 mesh typical); the manufacturer emphasizes that the design allows even difficult materials to pass without clogging, often with rubber balls or ultrasonic cleaners to keep meshes clear.

Design & Operation: The YBS swing screen features a sealed enclosure and quick-release clamping ring (open rapidly without tools) for fast mesh changes. Grand highlights that its swing screens are built from stainless or carbon steel, with polished surfaces for easy cleaning. Two cleaning options exist: bouncing ball or ultrasonic. Bouncing balls keep mesh holes clear for sticky powders, while the ultrasonic device (Swiss-made) tackles electrostatic or ultra-fine blockage. Noise is low – under 80 dB by design – and the drive uses a standard motor (not a high-G vibrator), increasing reliability and lifespan. The overall effect is a high-capacity sieve that can handle coarse to medium powders without excessive wear or vibration.

Performance: Grand claims the Circular Swing Screen can achieve screening efficiencies up to 90–95% with an output 5 times that of a conventional vibration screen. In practical terms, this means large throughput. For example, one YBS-2000 unit (2.63 m²) with a 4 kW motor can process many tons per hour of granular material (exact capacity depends on material and mesh). The long residence and gentle roll motion ensure that each grain has multiple chances to pass through the screen. Because the motion spreads material evenly from center to edge, even relatively small screens process bulk material thoroughly. The max reported screen area (YBS-2200) is ~3.8 m² and even larger versions exist, making it suitable for large industrial lines.

Applications: The YBS swing screen shines where bulk solids need classification. It is not suitable for liquids, but handles a wide range of solid shapes – spherical, cylindrical, flat, or irregular – especially those that tend to clog in standard sieves. Common uses include: screening flour, grains, powdered chemicals, metal powders (coarser fractions), plastic pellets, building materials, and food ingredients. It is widely used in food, chemical, building, and metallurgy industries. When high capacity and continuous operation are needed (e.g. a production line), the YBS swing screen’s robust construction and dust-tight design (with dust collection) make it an industrial favorite. Its 24/7 support availability also underlines suitability for critical processes.

Advantages of the Circular Swing Screen: Grand advertises these strengths:

High throughput: up to 5× the output of conventional vibrators.

High accuracy: up to 90–95% screening efficiency.

Low clogging: nonlinear swing motion plus cleaning options prevent mesh blocking.

Versatility: suitable for many shapes/materials, including irregular and sticky types.

Ease of use: quick-release ring for screen change, low noise (<80 dB), sealed design.

Features and Design Comparison

Below is a summary comparison of key features, applications, and performance factors for Grand’s Ternary Screening Machine vs. Circular Swing Screen:

| Feature / Spec | Ternary Screening Machine (XF) | Circular Swing Screen (YBS) |

|---|---|---|

| Motion type | 3-axis vibratory (horizontal + vertical + inclined) | Circular-planar swing with vertical toss |

| Screen deck | Flat or conical screen with multi-layer option | Flat circular screen, 1–5 layers (usually 5) |

| Diameter/Screen area | 340–1400 mm (0.09–1.5 m²) | 600–2200 mm (0.29–3.8+ m²) |

| Motor power | 0.18–1.5 kW (single motor) | 0.25–5.5 kW (single/dual motors) |

| Vibration frequency | Medium/high (vibrating motor) | Low-frequency swing motion |

| Screen mesh range | Very fine (2–500 mesh) | Medium to fine (mesh depends on material, often 10–200 mesh) |

| Max screening layers | 1–5 layers | Up to 5 layers (standard) |

| Throughput | Lower throughput (smaller area, precise) | High throughput (large area, efficient) |

| Screening efficiency | Very high for fine powders | ≥90–95% under ideal conditions |

| Typical capacity | Pilot to mid-scale (kg/h to tons/h, depending on mesh) | Heavy industrial (tons per hour, dependent on mesh) |

| Noise | Moderate (machine oscillation) | Quiet design, <80 dB |

| Cleaning options | Simple (sometimes brushes or balls if needed) | Rubber balls, rotating brush, or ultrasonic (built-in) |

| Construction | Stainless steel contact parts, spring-mounted | Stainless/carbon steel, polished, with dust cover |

| Applications | Fine powders, pharmaceuticals, spices, resins | Bulk powders, grains, food, minerals, and industrial chemicals |

| Not suitable for | Bulk coarse material (inefficient for large particles) | Liquids or slurry screening |

| Unique advantages | Compact; exceptional fine mesh capability | Massive capacity; anti-clogging (swing motion + cleaning) |

From the table, it’s clear that the Ternary Screening Machine excels at high-precision, fine-material screening in a compact footprint. In contrast, the Circular Swing Screen offers large-area, high-throughput screening for bulk powders. The chart above provides a quick reference, while the paragraphs below highlight how their designs address different needs.

Screening Machine User Tutorial: Operating Insights

To get the best results from either machine, operators should follow Grand’s usage guidelines closely. For example, the Ternary unit’s vibration can be fine-tuned: adjusting the eccentric weights’ angle and mass on the vibratory motor changes the amplitude of horizontal vs. vertical motion. In a screening machine user tutorial context, this means beginners should experiment (safely) with weight configurations to optimize flow rate and screening efficiency for their product. The user manual also emphasizes only starting the screen under load no more than six times per hour to avoid motor heating (a common best practice).

For the Circular Swing Screen, operators should ensure the cleaning attachments are properly installed. Rubber ball or ultrasonic cleaners are standard; rubber balls are ideal for sticky or low-mesh materials, whereas ultrasonic is recommended for very fine or electrostatically charged powders. Grand provides full instructions on changing screens (quick-release clamp) and periodic maintenance (e.g. checking springs, lubrication). Because these are industrial systems, ensure any installation meets local safety and electrical codes.

Both machines require regular inspection of screen meshes. As Grand notes, a torn or worn mesh will compromise screen quality. Always keep spare meshes on hand. Providing operators with safety gear (goggles, ear protection) and following lockout/tagout procedures during maintenance are also crucial (as detailed in Grand’s manuals). While these user manuals are comprehensive (covering everything from grounding to replacement parts), a key takeaway is: proper setup and tuning are essential to achieve the touted efficiency and precision for each machine.

Advantages of Each Screening Machine

Both Grand screening solutions bring specific advantages to industrial processes. It is worth summarizing their strengths as Advantages of Screening Machine (Grand models):

Efficiency and Accuracy: Both designs achieve high efficiency. The Ternary machine’s triple-movement provides thorough sieving on even a small screen, while the Circular Swing Screen reaches 90–95% efficiency at high throughput.

Reduced Clogging: The swing screen’s non-linear motion and cleaning balls dramatically cut clogging, a common headache in fine-material screening. The Ternary screen’s continuous spiral motion also resists blinding on fine meshes.

Modularity and Scalability: Grand’s machines support multiple decks (1–5 layers), allowing multi-fraction separation in one unit. Additional decks can be added as needed for capacity or grading.

Easy Maintenance: Quick-open rings and sealed housings make routine maintenance easier. Both units emphasize long-lived components – e.g. ordinary motors (instead of high-wear vibrators) in the swing screen, and standard bearings in both.

Versatility: With appropriate meshes, the Ternary Screen handles anything from powders to slurries, and the Swing Screen handles a broad range of solid forms (irregular, sticky, etc.).

In summary, Grand’s Ternary Machine is best when precision and fine mesh screening are paramount, whereas the Circular Swing Screen is ideal when large volume and clog-resistant separation are needed. Choosing between them depends on feed material characteristics (particle size, shape, moisture), required capacity, and desired cut sizes.

Quantitative Comparison Table

| Specification | Ternary (XF) | Circular Swing (YBS) |

|---|---|---|

| Screening Diameter (mm) | 340–1400 | 600–2200 |

| Screen Area (m²) | 0.09–1.5 | 0.29–3.8 (YBS-2200) |

| Layers | 1–5 | Up to 5 (usually 5) |

| Mesh Size Range | 2–500 mesh | (Typically 10–200 mesh, depending on use) |

| Motor Power (kW) | 0.18–1.5 | 0.25–5.5 |

| Vibration Frequency | Medium-high | Low-frequency swing motion |

| Noise Level | Moderate | <80 dB (quiet design) |

| Dimensions (length × width) | Small footprint (compact cylinder) | Larger footprint (needs 1.2–3.6 m² floor) |

| Material Suitability | Powders & fine granules | Powders, grains, irregular solids |

| Cleaning Method | Manual/ball cleaning is optional | Rubber ball, brush, or ultrasonic |

This table pulls directly from Grand’s own specs and highlights the real numbers. For example, note that a 1.13 m² screening area is achieved by a 1200 mm circular screen, whereas a 1.5 m² area requires a much larger 1400 mm ternary screen. Likewise, motor power for the 1200 mm models is 0.75 kW (ternary) versus 2.2 kW (swing) – reflecting the swing screen’s larger moving mass.

Conclusion and Inquiry Call-to-Action

In conclusion, Grand’s Ternary Screening Machine and Circular Swing Screen each offer engineered solutions for different screening challenges. The ternary machine is a precision, fine-particle classifier with a unique tri-axial motion and compact design. The circular swing screen is a high-capacity, anti-clogging separator with a large circular screening area and an advanced cleaning system. Both comply with industrial standards and are backed by Grand’s support.

Industrial buyers should match machine to material: use the XF Ternary Screen for ultra-fine or multi-layer fine sieving, and choose the YBS Circular Swing Screen for bulk powder processing or when mesh blinding is an issue. Each machine’s quantitative specs are documented above for precise planning.

Ready to optimize your process with Grand’s screening solutions? Submit an inquiry today to discuss your material, production rate, and desired cut size. Our engineers will recommend the right screening machine for your application.