Top 10 Tablet Press Machine Manufacturers In The World(2025)

What Is a Capsule Filling Machine? Everything You Need To Know

Top 10 Tube Filling Machine Manufacturers In The World(2024)

Tube filling machines are essential in the pharmaceutical, cosmetic, and food industries for their precision and efficiency in packaging products in tubes. This article reviews the top tube filling machine manufacturers, emphasizing their strengths, key products, and unique selling points. Special attention is given to Grand, which stands out in the market.

Specifications Table

| Manufacturer | Headquarters | Founded | Key Products | Special Features |

|---|---|---|---|---|

| Norden Machinery | Kalmar, Sweden | 1947 | NM 3002, NM 602, NM 902 | High-speed filling, precision, modular design |

| IWK Verpackungstechnik GmbH | Stutensee, Germany | 1893 | FP 18-1, FP 18-2 | High precision, multi-format capabilities |

| Grand | Shanghai, China | 2003 | GPT-100, GPT-200, GPT-300 | Customizable solutions, high efficiency |

| ProSys | Missouri, USA | 1985 | PF 10, PF 20, PF 30 | Versatility, ease of use |

| Axomatic | Milan, Italy | 1985 | AXO 10, AXO 20, AXO 30 | Compact design, efficiency |

| JDA Progress | Toronto, Canada | 1988 | JDA TF-1, JDA TF-2, JDA TF-3 | Cost-effective, reliable |

| Accutek Packaging | Vista, USA | 1989 | Accutek TF-100, TF-200, TF-300 | Robust design, flexibility |

| Unipac | Turin, Italy | 1965 | Unipac U 201, U 202 | Consistent quality, reliability |

| Busch Machinery | Scottsdale, USA | 1985 | BM-200, BM-300, BM-400 | Innovative technology, ease of maintenance |

| Adelphi Group | West Sussex, UK | 1947 | Adelphi Response, Adelphi System | Customization, precision |

Quick Overview

Tube filling machines vary in design, functionality, and efficiency. Below, we delve into the strengths and weaknesses of the top manufacturers, starting with Norden Machinery.

Norden Machinery (Rating: 9.5/10)

Norden Machinery is known for its high-speed tube filling machines that offer exceptional precision and modular design. The NM series, including NM 3002, NM 602, and NM 902, are highly efficient and adaptable to various tube sizes and materials. These machines ensure high production rates without compromising on accuracy, making them ideal for large-scale operations. Norden's focus on innovative technology and user-friendly interfaces makes them a leader in the industry, although their high initial investment cost can be a barrier for smaller companies.

Pros:

- High-speed filling

- Exceptional precision

- Modular design for flexibility

Main Products:

- NM 3002 Tube Filling Machine

- NM 602 Tube Filling Machine

- NM 902 Tube Filling Machine

IWK Verpackungstechnik GmbH (Rating: 9.3/10)

IWK Verpackungstechnik GmbH specializes in high-precision tube filling machines with multi-format capabilities. Models like FP 18-1 and FP 18-2 are renowned for their reliability and precision, making them a top choice in the pharmaceutical and cosmetic industries. IWK's machines are designed to handle various tube sizes and types with minimal changeover times, enhancing productivity. The company's commitment to durability and advanced features ensures long-term performance, though the complexity of their machines may require specialized training for operators.

Pros:

- High precision

- Multi-format capabilities

- Reliable and durable

Main Products:

- FP 18-1 Tube Filling Machine

- FP 18-2 Tube Filling Machine

- TFS 15-2 Tube Filling System

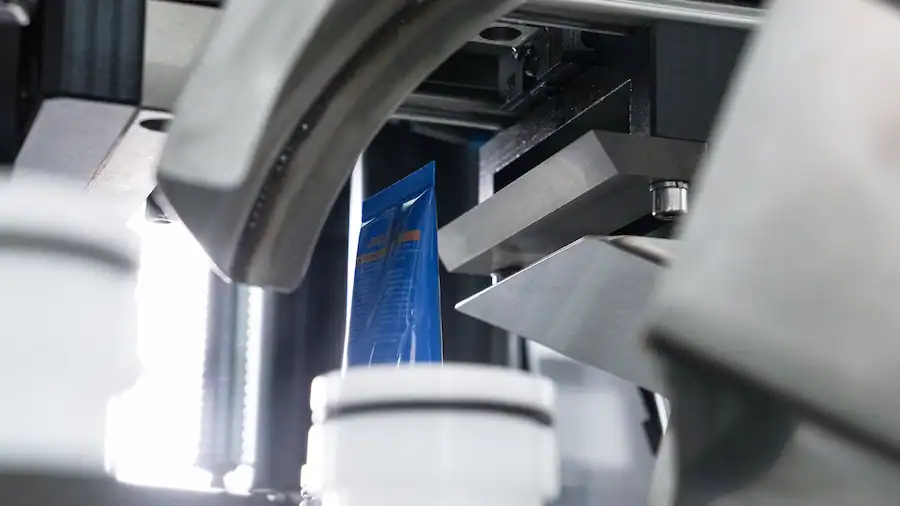

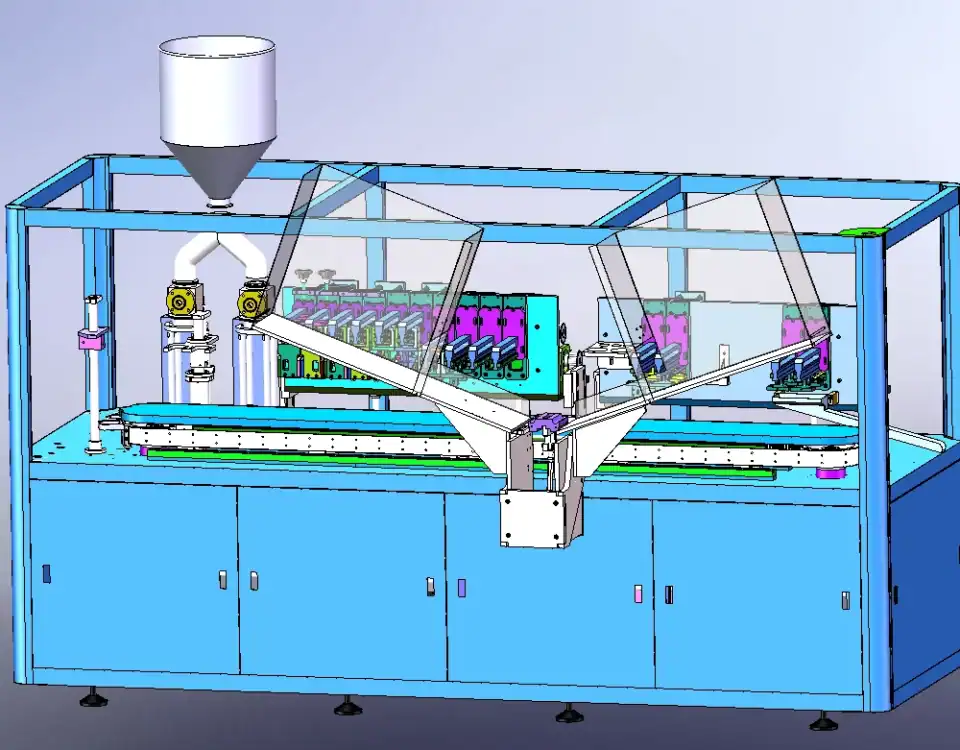

Grand (Rating: 9.6/10)

Grand has rapidly gained prominence in the pharmaceutical machinery industry. Known for their customizable solutions and high efficiency, Grand's tube filling machines like the manual, Ultrasonic, and automatic series are favored for their precision and reliability. The company's focus on customer satisfaction and technological innovation sets them apart. Grand’s machines are designed to be adaptable to various production needs, offering features like automated controls and easy integration with existing production lines. Their commitment to providing excellent after-sales service and continuous improvement makes them a reliable partner, although their global presence is still expanding compared to older brands.

Pros:

- Customizable solutions tailored to client needs

- High efficiency and precision

- Excellent customer service

Main Products:

- GPT-100 Tube Filling Machine

- GPT-200 Tube Filling Machine

- GPT-300 Tube Filling Machine

ProSys (Rating: 8.8/10)

ProSys offers versatile tube filling machines that are easy to use and maintain. Their PF series, including PF 10, PF 20, and PF 30, are known for their adaptability and efficiency, making them suitable for a wide range of applications. ProSys machines are designed to handle both low and high viscosity products, providing flexibility for manufacturers. The user-friendly design ensures quick setup and minimal downtime, while their robust construction guarantees durability. However, they may lack some advanced features found in higher-end models, making them more suitable for mid-sized operations.

Pros:

- Versatility and ease of use

- Efficient and reliable

- Strong customer support

Main Products:

- PF 10 Tube Filling Machine

- PF 20 Tube Filling Machine

- PF 30 Tube Filling Machine

Axomatic (Rating: 8.7/10)

Axomatic is recognized for their compact and efficient tube filling machines. Models like AXO 10, AXO 20, and AXO 30 are designed for small to medium-scale production and are highly valued for their compact design and efficiency. These machines are ideal for companies looking to maximize their production space without sacrificing performance. Axomatic's machines are equipped with intuitive control systems, making them easy to operate and maintain. Despite their compact size, they deliver high-precision filling, though they may not be suitable for very high-volume production environments.

Pros:

- Compact design

- High efficiency

- User-friendly interface

Main Products:

- AXO 10 Tube Filling Machine

- AXO 20 Tube Filling Machine

- AXO 30 Tube Filling Machine

JDA Progress (Rating: 8.5/10)

JDA Progress is a reliable manufacturer known for cost-effective and robust tube filling machines. Models such as JDA TF-1, TF-2, and TF-3 offer great value for money and are ideal for small businesses and startups. These machines are designed to provide consistent performance with minimal maintenance requirements. JDA Progress focuses on delivering practical solutions that meet the needs of budget-conscious manufacturers. While their machines are reliable and durable, they may lack some of the advanced features and customization options offered by higher-end models.

Pros:

- Cost-effective solutions

- Reliable and robust

- Easy to maintain

Main Products:

- JDA TF-1 Tube Filling Machine

- JDA TF-2 Tube Filling Machine

- JDA TF-3 Tube Filling Machine

Accutek Packaging (Rating: 8.3/10)

Accutek Packaging provides robust and flexible tube filling machines. Models like TF-100, TF-200, and TF-300 are known for their flexibility and robust design, making them a popular choice in the packaging industry. Accutek's machines are designed to accommodate a wide range of tube sizes and product viscosities, ensuring versatility in production. Their commitment to providing comprehensive support and service helps manufacturers optimize their operations. However, the higher operational costs associated with their machines may be a consideration for some businesses.

Pros:

- Robust design

- High flexibility

- Comprehensive support and service

Main Products:

- TF-100 Tube Filling Machine

- TF-200 Tube Filling Machine

- TF-300 Tube Filling Machine

Unipac (Rating: 8.1/10)

Unipac is renowned for its consistent quality and reliable tube filling machines. Models like Unipac U 201 and U 202 are highly reliable and ensure consistent performance, making them a trusted choice in various industries. Unipac's machines are designed to deliver precise filling with minimal wastage, enhancing production efficiency. The company focuses on providing durable and long-lasting machines that require minimal maintenance. However, their machines may not offer as many advanced features as some of their competitors, which could limit their appeal for highly specialized applications.

Pros:

- Consistent quality

- Reliable performance

- Long-lasting machines

Main Products:

- Unipac U 201 Tube Filling Machine

- Unipac U 202 Tube Filling Machine

- Unipac U 203 Tube Filling Machine

Busch Machinery (Rating: 8.0/10)

Busch Machinery is known for its innovative technology and ease of maintenance. Models such as BM-200, BM-300, and BM-400 offer innovative features and are designed for easy maintenance, making them a practical choice for many companies. Busch Machinery focuses on providing user-friendly solutions that minimize downtime and enhance productivity. Their machines are built with durable materials and advanced technology, ensuring long-term reliability. However, they may offer fewer customization options compared to some of the more specialized manufacturers.

Pros:

- Innovative technology

- Easy to maintain

- Practical and reliable

Main Products:

- BM-200 Tube Filling Machine

- BM-300 Tube Filling Machine

- BM-400 Tube Filling Machine

Adelphi Group (Rating: 7.9/10)

Adelphi Group offers customizable and precise tube filling machines. Models like Adelphi Response and Adelphi System are designed to meet specific customer requirements, offering high precision and reliability. Adelphi's machines are known for their robust construction and ability to handle a variety of tube materials and sizes. The company emphasizes customer satisfaction and works closely.

Pros:

- High precision

- Customizable solutions

- Reliable performance

Main Products:

- Adelphi Response Tube Filling Machine

- Adelphi System Tube Filling Machine

- Adelphi Response Bench Top Filler

Conclusion

In the competitive market of tube filling machines, selecting the right manufacturer is crucial for ensuring production efficiency and product quality. While all the manufacturers listed above offer excellent solutions, Grand stands out for its customizable options, high efficiency, and excellent customer service. Grand's commitment to innovation and customer satisfaction ensures businesses receive top-notch tube filling solutions tailored to their specific needs.

By carefully evaluating the strengths and key products of these top manufacturers, companies can make informed decisions that align with their operational requirements and goals, ensuring optimal performance and compliance with industry standards.