Is a Sugar Coating Machine Really the Best Choice?

What are the common packaging of cold medicines?

What Size Pills Can a Pill Press Make? Understanding Pill Size, Tooling & the GZPK-26

"When clients ask about pill sizes our machines can make, I tell them the real question is, 'What size and shape do you need?'" says Bruce Fu, a leading expert at Grand. "The machine provides the power, but the tooling is where the magic happens. We design it around the customer's vision, because for us, the customer's tooling needs always come first."

machines can make, I tell them the real question is, 'What size and shape do you need?'" says Bruce Fu, a leading expert at Grand. "The machine provides the power, but the tooling is where the magic happens. We design it around the customer's vision, because for us, the customer's tooling needs always come first."

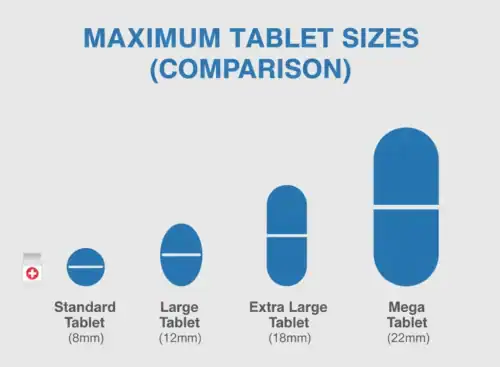

Grand's expert perspective gets to the heart of tablet manufacturing. The versatility of a modern tablet press is immense, but its output is defined by its tooling. To give a concrete example, the high-performance Grand GZPK-26 can produce tablets with a maximum diameter of 25mm. In this guide, we'll look at the key principles behind this flexibility. We'll also cover important maintenance tips and show you how to start using your own Grand tablet press.

Understanding Tablet Press Machine Principles: How They Work

A tablet press compresses powder or granules into tablets of consistent weight and size. To understand their capabilities, we must look at their evolution and mechanics.

From Single Punch to High-Speed Rotary: An Evolution in Efficiency

Early tablet presses were single-punch machines. They used one die and two punches that moved vertically to compress material. While they worked for small-scale production, producing about 60-100 tablets per minute, they had major drawbacks. Pressure was uneven, leading to inconsistent density. This often caused problems like splitting or cracking, known as "lamination."

To address these issues, engineers created the rotary tablet press. This design features multiple punches and dies on a rotating turret. As the turret rotates, punches pass through various stations that perform tasks simultaneously.

A key innovation is the compression method. Instead of a sudden impact, it uses sustained, gradual pressure. This allows trapped air to escape from the die cavity. The result is more uniform tablet density, less splitting, and much higher production output.

Modern manufacturing relies on high-speed rotary tablet presses, like the Grand GZPK-26. These rotary presses maintain a linear speed of at least 60 meters per minute. They are fully automatic machines, crucial for the pharmaceutical, chemical, and food industries.

For example, the GZPK-26 can produce up to 160,000 tablets per hour.

The Heart of the Machine: How a Rotary Tablet Press Creates Pills

A high-speed rotary tablet press consists of precisely designed parts that work together. Key components include the turret, punches and dies, a feeding mechanism, filling adjustment, upper and lower punch guide rails, and a pressure adjustment mechanism. The tablet formation process involves several stages as the turret rotates.

The Step-by-Step Process of Tablet Formation

Each turret rotation takes the die set through a continuous cycle of filling, compression, and ejection, producing a finished tablet.

- Feeding: The process starts with raw material. High-speed presses use a forced feeding mechanism to ensure a steady flow of powder into the die cavities. Motors drive impellers that push the material into the open dies below. This active feeding is vital for high-speed operation, as gravity-fed systems are not sufficient.

- Filling & Dosing (Weight Adjustment): After feeding, the machine determines the tablet's weight. This is done by controlling the die cavity's volume, not by weighing the powder. The lower punch is pulled down, and excess powder is scraped off. The remaining material in the die sets the tablet's weight. This filling amount is controlled by how far the lower punch descends, adjustable by a synchronous motor that responds to the control system, monitoring pressure on the rollers.

- Pre-Compression: Before the main compression, punches pass through pre-compression rollers. This stage is crucial. It applies light force to the powder, removing much trapped air. This densifies the powder, improves compactability, and enhances tablet quality. The GZPK-26 applies a pre-pressure of 20KN.

- Main Compression: This is where the tablet forms. The upper and lower punches, filled with pre-compressed powder, pass between heavy-duty rollers. These rollers exert high pressure, compacting the material into a solid tablet. Maximum pressure occurs when punches are closest together, ensuring hardness and stability. The GZPK-26 applies a main pressure of 100KN.

- Ejection and Take-off: After passing the rollers, the upper punch lifts away. The lower punch pushes the finished tablet up, making it flush with the die table. A take-off blade guides the tablet into a discharge chute, restarting the cycle. The system usually has a rejection mechanism. It uses compressed air to blow out-of-spec tablets into a separate channel. This way, only quality products are collected.

The Decisive Factor: How Tooling Determines Pill Size and Shape

The size, shape, and dosage of a tablet depend on the punch and die set, also known as tooling.

- Dies: The die molds the tablet. The hole's size determines its diameter and shape. This can be circular, oval, or custom shapes like stars, squares, or triangles. For the GZPK-26, the standard die diameter is 38.1mm, allowing for 25mm tablets.

- Punches: The upper and lower punches compress the material. The tips determine the tablet's thickness and surfaces. They can be flat, concave, or convex, and can be engraved with designs.

A single tablet press can produce an almost infinite variety of tablets. By swapping out tooling, manufacturers can easily change production from small, round 5mm pills to large, oblong 25mm tablets.

Essential Rotary Tablet Press Maintenance for Peak Performance

A high-speed rotary tablet press, such as the Grand GZPK-26, is a significant investment. Regular maintenance is crucial for machine longevity, safety, and consistent product quality.

Lubrication: The Lifeblood of Your Tablet Press

Proper lubrication is critical. High-speed presses use centralized lubrication systems to protect moving parts. These machines often have two systems.

- Thin Oil Automatic Lubrication System: This automated system is controlled by the PLC. It delivers precise amounts of thin oil (like No. 30 machine oil) to essential components. It collects used oil in a waste reservoir that needs periodic emptying. Lubrication frequency can be set to run after every 200-300 rotations.

- Dry Oil (Grease) Lubrication System: This manual system services components like lever mechanisms. Operators apply grease (such as No. 00 boron nitride high-temperature grease) before each shift. A couple of pumps are typically enough for proper lubrication.

Key System Maintenance

In addition to lubrication, some systems need regular checks.

- Feeder Calibration: The gap between the feeder and turret surface must be 0.05mm. If too large, powder leaks; if too small, friction occurs. Calibration requires loosening bolts and adjusting height with a feeler gauge.

- Hydraulic System: This system controls machine pressure. Operators must check hydraulic fluid levels regularly. The fluid should not drop below a specified height (e.g., 5mm) at maximum pressure. Recommended fluid is typically a specific grade of turbine oil (like No. 22 turbine oil).

- Worm Gear Reducer: This part drives the turret and generates heat, so it needs good ventilation. The oil level must be checked regularly.The oil level should be checked regularly via the sight glass, and the oil (e.g., No. 460 gear oil for winter or No. 680 for summer) should be completely replaced after every 400-500 hours of operation.

How to Purchase a Grand Tablet Press Machine

If you are ready to enhance your production capabilities with a high-performance Grand tablet press like the GZPK-26, our team is here to help. We have made the inquiry process simple and direct.

To receive a personalized quote or more detailed information, please fill out the inquiry form located on the right side of this blog. Our dedicated sales representatives will review your request and contact you promptly with the details you need.

Alternatively, you can reach out to our sales team directly. Please send an email outlining your production requirements to sales@grandpackmachine.com. We look forward to helping you find the perfect tablet press solution for your business.

GZPK-26 Tablet Diameter

| Specification | Value |

|---|---|

| Max. Tablet Diameter | Φ 25 mm |

Other Parameters

- Model: GZPK-26

- Number of Stations: 26

- Max. Capacity: 160,000 tablets/hour

- Main Pressure: 100 KN

- Pre-pressure: 20 KN

- Max. Filling Depth: 20 mm

- Die Diameter: 38.1 mm

- Net Weight: 2000 KGS