Capsule Automatic Filling Machine-NJP-1250

Nowadays, hard, soft, and pellet capsules are commonly used by worldwide consumers. However, manual capsule filling reduces the supply efficiency of machine shops (factories) and affects consumers' utilization. Our Automatic Filling Machine - NJP-1250 can assist you in overcoming this situation and achieve automatic capsule filling.

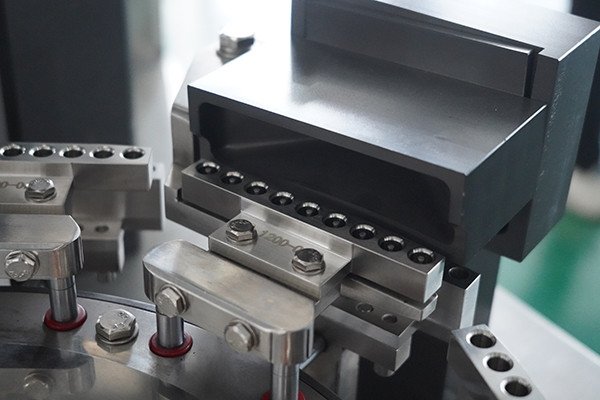

No More Annoying Leaks

The three-dimensional adjustable disc measures the gap between the plate and the copper ring evenly, which helps avoid powder leakage and the loading difference.

Faster, cleaner maintenance

It is made for swift leaf removal and hose access for cleaning. Disassembly and reassembly is a snap since it’s modular. Clean and simple assembly/disassembly means quick and straightforward repairs, and you don’t have to worry about digging through elaborate manuals or waiting weeks for service.

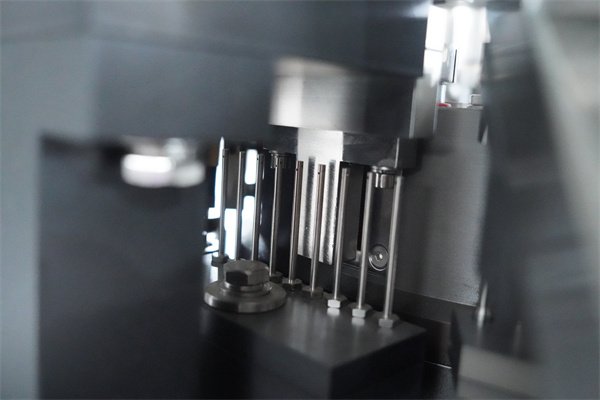

Powder Feeding Redesign

To save space and maintain the cleanliness of the working environment, we have reengineered the powder feeding process. There will be no more powder explosion issues.

.

.

Features

Contamination-free

After loading the capsules, the entire turntable is sealed and processed in rotation. No empty capsules and powder would be left on the counter!

Neat capsule dispenser

Capsules are dispensed through the capsule outlet orderly. No mess and no popping capsules.

Automatic Powder Feeding

The powder vacuum feeding system eliminates the requirement of manual powder feeding and liberates labor. Simply press the start button then hands-free!

Specifications

| Output: | 75000Grain/hour |

| Machine weight: | 1200Kg |

| Machine Dimensions: | 1085(+339)mm*1015(+339)mm*1890mm |

| Power Supply: | 380/220V 50Hz |

| Motor power: | 5.6KW(Standard ) |

| Number of holes: | 9holes |

| Vacuum: | Extraction rate48m3/h -0.03~-0.05Mpa |

| Dust: | 20Kpa 210m3/h |

| Noise: | <75DB(A) |

| Making rate: | Empty capsules99.8% Full Capsule99.8% |

| Suitable for Capsule: | 000、00、0,1,2,3,4、5# |

| Filling error: | ±2%-±3.5% |

Machine Details

Sealed turntable

Capsule outlet

Vacuum feeding machine

Capsule Filling Module

Capsule Filling Ring

Capsule Waste rejection device