Top 8 pharmaceutical packaging line manufacturers in the world-GRAND

High-End Pharmaceutical Machinery Analysis – Capsule Counter & More

The Most Comprehensive Guide to Bottle Washing Machines – Essential for Liquid Filling Lines

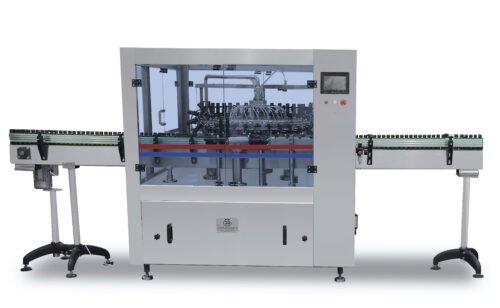

In the fast-paced world of pharmaceutical, food, and health products manufacturing, having reliable and efficient equipment is paramount. One such crucial piece of equipment is the bottle washing machine, an indispensable part of the liquid filling line.

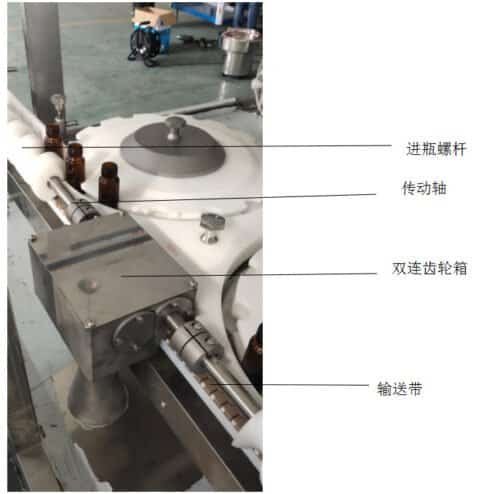

1. Bottle inlet screw and bottle inlet dial

2. Bottle washing parts

3. Bottle outlet screw and bottle outlet dial

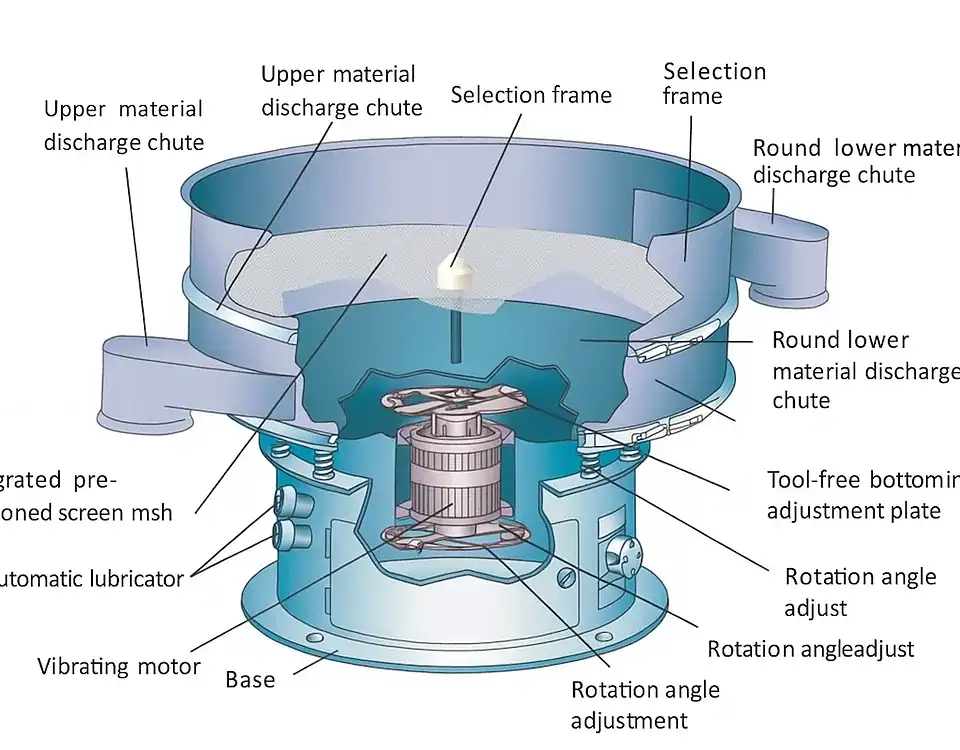

4. Frame rotating parts

5. Conveyor belt

6. Electrical operation interface

This article aims to provide an in-depth exploration of the bottle washing machine, highlighting its importance in the liquid filling process, key features, and considerations for choosing the best machine for your production line.

It will also explore the technological advancements, industry standards, and best practices related to bottle washing and filling.

Introduction to Bottle Washing Machines in Liquid Filling Lines

A bottle washing machine is designed to thoroughly clean bottles before they are filled with liquid, ensuring the hygiene and safety of the product. In the pharmaceutical, food, and cosmetic industries, it is vital that bottles are free of contaminants, such as dust, oils, or residues from previous products. The washing process is an integral part of the liquid filling line, as it ensures the final product meets strict quality and safety standards.

Liquid filling line bottle washing machine plant

The primary function of the bottle washing machine is to clean the inside and outside of the bottle using water, air, and sometimes specialized cleaning agents. Depending on the industry and specific production requirements, the bottle washing machine can handle various bottle sizes and cleaning procedures.

How Does a Bottle Washing Machine Work?

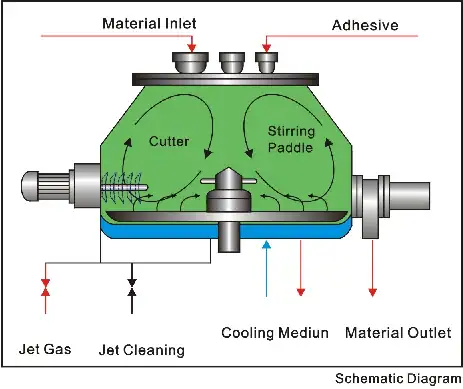

Typically, a bottle washing machine operates by using mechanical components to move bottles through a series of cleaning stages. These stages usually include:

- Pre-rinsing: Bottles are first rinsed with water or air to remove any loose debris.

- Main washing: Bottles are subjected to a more thorough cleaning process involving a combination of water, air, and sometimes detergents or disinfectants.

- Rinsing: After the main wash, bottles are rinsed with purified or sterile water to remove any remaining cleaning agents or impurities.

- Drying: Some bottle washing machines also feature a drying stage to ensure that bottles are completely dry before filling.

- Post-wash inspection: Many systems also include a final inspection stage to ensure the bottles are thoroughly cleaned and free from contaminants.

Importance of Bottle Washing Machines in Liquid Filling Lines

In a liquid filling line, maintaining a high standard of hygiene and cleanliness is critical for ensuring product safety. Contaminated bottles can lead to a range of issues, from product contamination. The washing process plays a vital role in preventing these issues by ensuring that each bottle is free of harmful particles or residues before it is filled.

The bottle washing machine serves as the first step in ensuring that bottles are adequately prepared for the filling process. If bottles are not properly cleaned, it may lead to contamination during filling, posing significant health risks for consumers. Additionally, proper bottle cleaning helps reduce the risk of microbial growth in liquid products, such as pharmaceuticals, which could lead to unsafe products reaching the market.

Key Features of a Bottle Washing Machine

A bottle washing machine is equipped with several features designed to ensure optimal cleaning and hygiene. These include:

Adjustable Settings: Many bottle washing machines come with adjustable settings for water pressure, air pressure, and temperature, allowing manufacturers to fine-tune the machine according to the specific cleaning requirements of different bottle sizes and materials.

High-Pressure Washing: To ensure thorough cleaning, bottle washing machines often use high-pressure sprays of water, air, or a combination of both. This helps remove even the most stubborn residues and contaminants from the bottles.

Sterilization Capabilities: In the pharmaceutical industry, it is essential to sterilize bottles to prevent contamination. Some bottle washing machines come with additional sterilization stages using hot water or steam to kill any remaining microorganisms.

Energy Efficiency: Modern bottle washing machines are designed to be energy-efficient, minimizing water and energy consumption while maintaining high cleaning standards. Some systems incorporate energy-saving features such as heat recovery or recycling of water.

Advantages of Using a Bottle Washing Machine in a Liquid Filling Line

Improved Product Quality: By thoroughly cleaning and sterilizing bottles before they are filled, bottle washing machines ensure that the product inside the bottle remains uncontaminated and safe for consumption.

Increased Production Efficiency: Automated bottle washing machines can significantly increase the efficiency of a liquid filling line. These machines are designed to handle high volumes of bottles quickly and efficiently, reducing the need for manual labor and minimizing downtime between production batches.

Compliance with Industry Regulations: In regulated industries like pharmaceuticals and food production, compliance with stringent hygiene standards is essential. Bottle washing machines are designed to meet these regulatory requirements, including GMP (Good Manufacturing Practice) and FDA guidelines, ensuring that products meet all necessary safety standards.

Reduced Risk of Contamination: A clean bottle is crucial to minimizing the risk of product contamination. Bottle washing machines remove any contaminants from bottles before filling, reducing the risk of microbial contamination, which could lead to recalls, legal issues, or even harm to consumers.

Cost Savings: Although purchasing a bottle washing machine represents an upfront investment, the long-term benefits include reduced labor costs, increased production speed, and minimized waste from contamination or product recalls.

Considerations When Choosing a Bottle Washing Machine for a Liquid Filling Line

When selecting a bottle washing machine for your liquid filling line, several factors need to be considered:

Bottle Size Compatibility: Ensure the machine is capable of handling the size and shape of the bottles you intend to use. Some machines are designed to accommodate a range of bottle sizes, while others may be limited to specific dimensions.

Cleaning Method: Depending on your product, you may require different types of cleaning methods. For instance, in pharmaceutical manufacturing, you may need a machine that offers both high-pressure washing and sterilization capabilities.

Energy Efficiency: Evaluate the energy consumption of the machine. High-efficiency machines not only save on utility costs but also reduce your environmental footprint.

Ease of Maintenance: Choose a machine that is easy to maintain and clean. A machine that is difficult to clean may lead to cross-contamination or build-up of residues, which can affect the quality of the final product.

Automation and Integration: Modern bottle washing machines can be automated and integrated into the overall liquid filling line. This integration can help streamline production, reduce human error, and increase efficiency.

Conclusion

The bottle washing machine is a critical component of any liquid filling line. Its primary function is to ensure that bottles are thoroughly cleaned before they are filled with liquid products, preventing contamination and ensuring product safety. By improving product quality, enhancing production efficiency, and reducing the risk of contamination, bottle washing machines play an indispensable role in manufacturing operations across a range of industries, including pharmaceuticals, food, and cosmetics.

When selecting a bottle washing machine, it is essential to consider factors such as bottle size compatibility, cleaning methods, energy efficiency, and ease of maintenance. By investing in a high-quality bottle washing machine that meets your specific production requirements, you can significantly improve the efficiency, safety, and compliance of your liquid filling line, ensuring the production of high-quality products for consumers.