High-End Pharmaceutical Machinery Analysis – Capsule Counter & More

The Steady Force Behind Modern Technology: The Deep Integration of Pharmaceutical Packaging Machinery and Computer Science

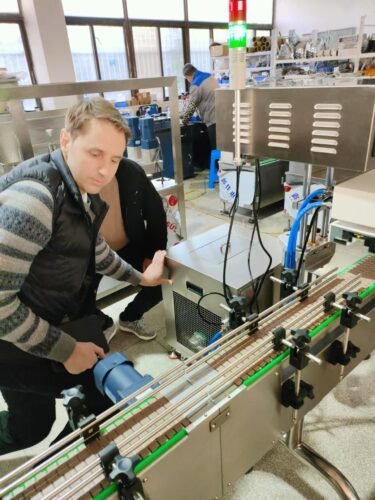

Customer visits the Pharmaceutical Packaging Line at Grand

The Pharmaceutical Packaging Line plays a crucial role in ensuring the safety, efficiency, and compliance of pharmaceutical products. At Grand, we provide a state-of-the-art facility where clients can witness firsthand the advanced processes that make pharmaceutical packaging both precise and reliable. Our visitors gain valuable insights into how automated technology, rigorous quality control, and innovative solutions come together to optimize pharmaceutical packaging.

A Warm Welcome to Grand

Clients arriving at Grand are greeted with a comprehensive introduction to our Pharmaceutical Packaging Line. Our team provides an overview of the facility, emphasizing the importance of high-quality packaging in the pharmaceutical industry. With increasing global regulations and a demand for safe medication, a well-structured Pharmaceutical Packaging Line ensures compliance and efficiency.

Our facility features cutting-edge automation, precise packaging machinery, and strict quality control measures. Every step, from primary packaging to secondary packaging, is designed to meet the highest industry standards. Visitors are encouraged to explore each phase of the process, understanding how every component contributes to maintaining product integrity.

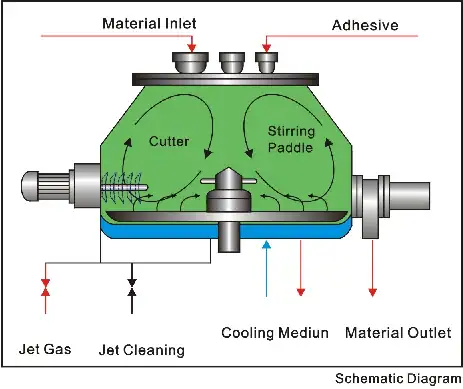

Advanced Automation in the Pharmaceutical Packaging Line

Automation is a game-changer in modern Pharmaceutical Packaging Lines. At Grand, we showcase high-speed automated systems that handle packaging with remarkable accuracy. These machines significantly reduce human errors and increase production efficiency, ensuring that every package meets strict pharmaceutical regulations.

Customer visiting

- Automated Blister Packing: This process ensures that tablets and capsules are securely sealed, maintaining their efficacy and protection against contamination.

- High-Speed Cartoning Machines: These machines swiftly package products into cartons, optimizing speed and efficiency.

- Serialization and Track-and-Trace Systems: Compliance with global pharmaceutical regulations requires accurate labeling and tracking. Our Pharmaceutical Packaging Lineintegrates advanced serialization systems for full traceability.

Customer visits the Pharmaceutical Packaging Line at Grand

Clients witnessing these systems in action can see how automation streamlines the pharmaceutical packaging process while enhancing overall safety.

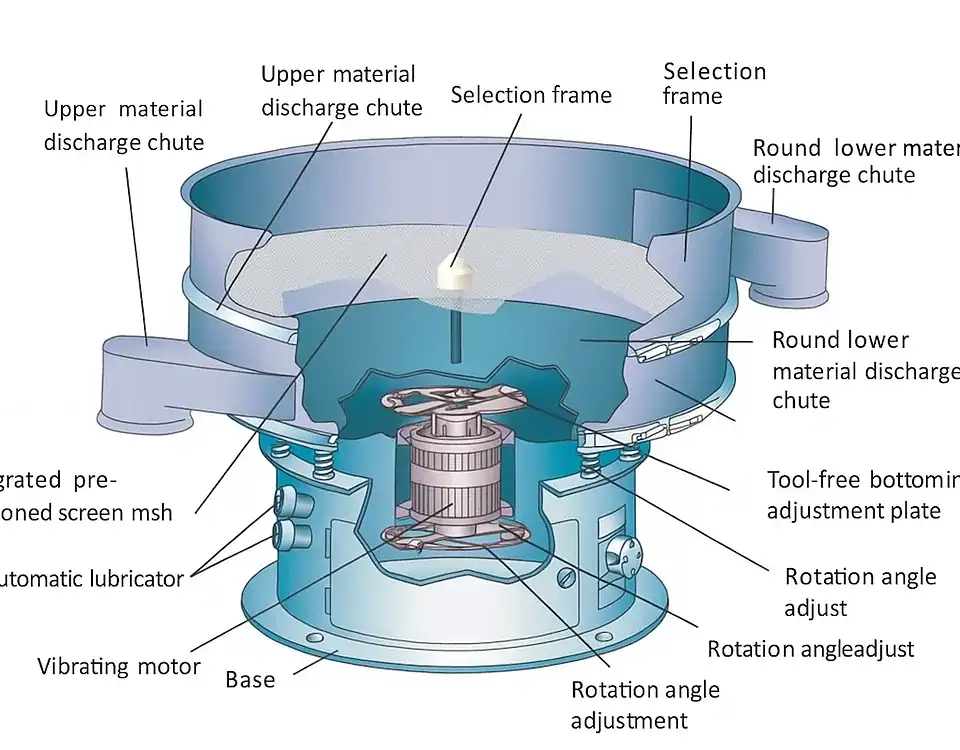

Quality Control: A Pillar of the Pharmaceutical Packaging Line

Maintaining quality is at the heart of every Pharmaceutical Packaging Line. At Grand, we implement rigorous quality control measures to ensure every packaged product meets the highest standards. Clients observe our quality assurance procedures, including:

- Vision Inspection Systems: These detect errors such as missing tablets, incorrect labeling, or faulty packaging, ensuring only flawless products reach consumers.

- Weight Verification: Precise weight measurement ensures that each package contains the correct dosage, reducing the risk of underfilling or overfilling.

- Tamper-Evident Sealing: Our sealing technology ensures product integrity, preventing contamination or counterfeiting.

Customer visits the Bottle unscrambler

Clients leave with a deep appreciation for how strict quality control safeguards the integrity of pharmaceutical products.

Regulatory Compliance in the Pharmaceutical Packaging Line

Compliance with international pharmaceutical regulations is non-negotiable. At Grand, we ensure that our Pharmaceutical Packaging Line meets all necessary industry standards, including:

- GMP (Good Manufacturing Practice): Ensuring products are consistently produced and controlled according to quality standards.

- FDA (Food and Drug Administration) Regulations: Compliance with stringent guidelines for pharmaceutical packaging.

- EU Falsified Medicines Directive (FMD): Ensuring that every product in the Pharmaceutical Packaging Linemeets track-and-trace requirements.

Try production line debugging

During the tour, clients gain insight into how compliance is seamlessly integrated into every aspect of the packaging process, reducing risks and ensuring consumer safety.

Customization and Flexibility in Pharmaceutical Packaging

Every pharmaceutical company has unique packaging needs. At Grand, we demonstrate how our Pharmaceutical Packaging Line can be tailored to accommodate various packaging formats, dosage forms, and branding requirements.

View customer's specific production requirements

- Custom Labeling and Branding: We offer personalized packaging solutions to enhance product presentation.

- Multi-Dose and Unit-Dose Packaging: Depending on the medication type, we provide customized solutions to suit different market demands.

- Flexible Batch Production: Our adaptable production lines allow for both large-scale manufacturing and small-batch production.

Clients leave with a clear understanding of how customization plays a key role in modern pharmaceutical packaging strategies.

Final Impressions and Future Collaborations

As the tour concludes, clients express their appreciation for the efficiency, precision, and innovation of our Pharmaceutical Packaging Line. They gain valuable knowledge about how advanced automation, quality control, regulatory compliance, and sustainability efforts contribute to world-class pharmaceutical packaging.

At Grand, we are committed to continuous improvement and collaboration with industry leaders. By offering cutting-edge Pharmaceutical Packaging Line solutions, we help businesses optimize their packaging processes while ensuring patient safety.

For companies looking to enhance their Pharmaceutical Packaging Line, Grand remains a trusted partner in delivering excellence and innovation.