Zero Defects in Extreme Environments | GRAND Capsule Fillers & Visual Inspection Systems

The Expert’s Guide to Shrink Wrap Machines

Grand GZPK-26 Rotary Tablet Press: High-Speed Smart Production

Category: Pharmaceutical Manufacturing | Reading Time: 12 mins

In the pharmaceutical industry, the tablet remains the king of dosage forms. It is stable, portable, and precise. But for the manufacturer, the tablet represents a challenge of scale. How do you turn tons of powder into millions of uniform, hard tablets without compromising quality?

The answer lies in the Rotary tablet press. While single-punch presses have their place in R&D, the rotary press is the beating heart of modern mass production.

Today, we are diving deep into the mechanics of these machines, comparing them to older technologies, and introducing the new standard in intelligent manufacturing: the Grand GZPK-26 Plus and its high-speed siblings like the ZP420 and ZP226-17D.

Part 1: What is a Rotary Tablet Press?

A rotary tablet press (often called a multi-station press) is a mechanical device that compresses powder into tablets of uniform size and weight. Unlike a single-punch machine that stamps one tablet at a time, a rotary press uses a rotating turret that holds multiple sets of punches (upper and lower) and dies.

How does a rotary press work?

The process is a continuous cycle of filling, compression, and ejection.

Filling: As the turret rotates, the lower punches pull down, creating a cavity in the die. Powder flows from the hopper, through a force feeder, into these cavities.

Metering: The lower punch is raised to a specific height to push out excess powder, ensuring the exact dosage volume is retained.

Compression: The upper and lower punches pass between large pressure rollers. These rollers force the punches together, compressing the powder into a solid tablet. Modern machines like the Grand GZPK-26 utilize pre-compression rollers (to release air) followed by main compression rollers (to form the tablet).

Ejection: The upper punch lifts, and the lower punch rises to push the finished tablet out of the die and into the discharge chute.

Is the rotary printing press still used today?

Absolutely. In fact, it is more vital than ever. The principle invented in the late 19th century has been supercharged with modern automation. Without rotary presses, it would be impossible to meet the global demand for medications, vitamins, and supplements.

Part 2: Grand Series Overview – The Advantage of Intelligence

Not all rotary presses are created equal. The Grand Machinery series (specifically the GZPK and ZP lines) represents the evolution from simple mechanical pressing to "Intelligent Machinery."

Based on the latest technical configurations, here is why Grand presses stand out:

1. The GZPK-26 Plus: The Flagship of Intelligence

The GZPK-26 is designed for facilities that demand GMP compliance and smart control.

Siemens PLC Integration: The machine features a fully digital "Smart Line" interface. Operators can control turret speed, filling depth, and tablet thickness via a touchscreen, removing the guesswork of manual handwheels.

Dust-Free Feeding: As seen in the design, it integrates a QVC Vacuum Conveyor. This connects directly to the top of the press, sucking powder from the bin into the hopper. This closed-loop system prevents cross-contamination and protects operators from dust inhalation.

Force Feeding System: The detail shots of the "Feeding Station" show a sophisticated force feeder. Unlike gravity feeders, this uses rotating paddles to force powder into the dies, ensuring consistent weight even with poor-flowing materials.

p>GrandPack Automatic Tablet Press Series GZPK-26-New GrandPack Automatic Tablet Press Series GZPK-26-New

2. High-Speed Capacity (ZP420 & ZP226)

For mass production, speed is the metric that matters.

How fast is the rotary tablet press? The Grand ZP420 and similar high-speed models in this lineup boast capacities reaching up to 160,000 tablets per hour. This throughput is achieved by utilizing multi-tip tooling or simply running high-station turrets at optimized speeds.

Robust Turret Design: The turret is the most stressed part of the machine. Grand presses use high-grade steel turrets that resist the immense pressure required for hard tablets, minimizing wear on the punch guides.

Part 3: Single Punch Press vs. Rotary Press – What’s the Difference?

If you are setting up a new line, you might be debating between these two types. Here is the breakdown:

| Feature | Single Punch Press | Rotary Tablet Press (Grand ZP Series) |

| Throughput | Low (60-100 tablets/min) | High (2,000 - 3,000+ tablets/min) |

| Mechanism | Intermittent (Up/Down motion) | Continuous (Rotary motion) |

| Pressure Control | Limited control | Precision control with Pre-Compression |

| Filling Accuracy | Varies with speed | High accuracy via Force Feeder |

| Best Use Case | R&D, Clinical Trials, Pharmacy Compounding | Mass Production, Commercial Manufacturing |

The Verdict: If you are producing commercial batches, a rotary press is the only viable option. The single punch is strictly for formulation development.

Part 4: What Products Can You Make?

The Grand Rotary Tablet Press series is versatile. It isn't limited to standard white pills.

1. Pharmaceutical Tablets

This is the primary use case. The high compression force allows for the binding of difficult APIs (Active Pharmaceutical Ingredients). The pre-compression feature on the GZPK series is critical here—it gently squeezes the powder to remove entrapped air before the main force is applied, preventing "capping" (where the top of the tablet pops off).

2. Nutraceuticals & Vitamins

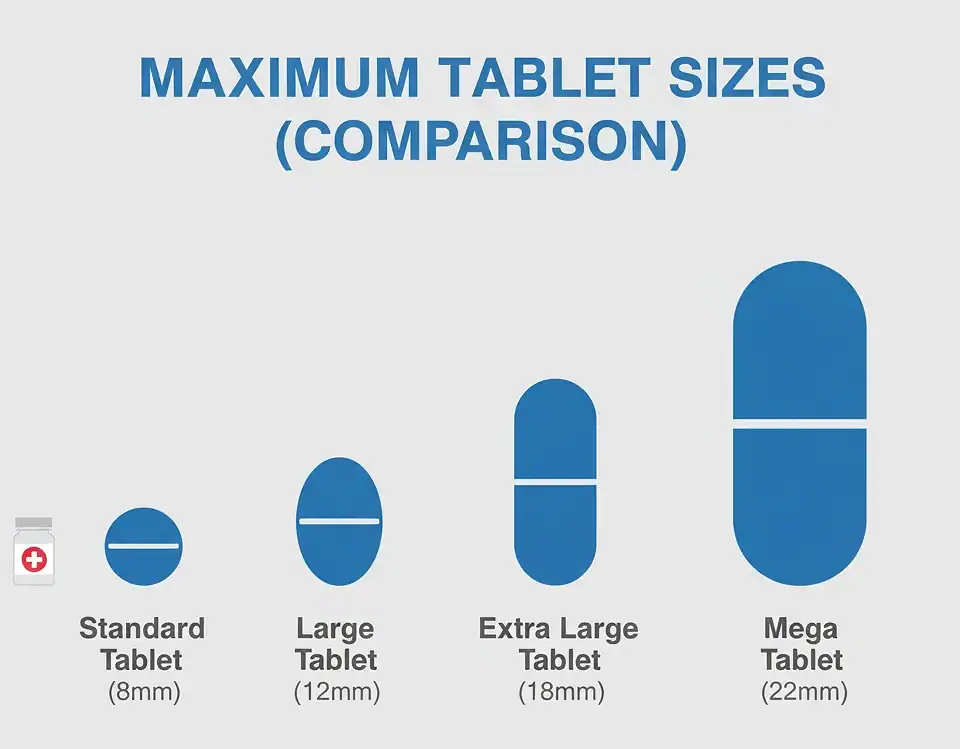

Large multivitamins often require high pressure and deep fill depths. Machines like the ZP420 are built with the torque necessary to compress large calcium or herbal tablets without stalling.

3. Effervescent Tablets

These are highly sensitive to moisture. The fully enclosed, plexiglass-shielded compression zone of the Grand presses creates an isolated environment, perfect for hygroscopic materials.

4. Dual-Layer Tablets

Advanced configurations of rotary presses can have two hoppers and two filling stations, allowing for the creation of bi-layer tablets (e.g., immediate release layer + sustained release layer).

Part 5: The Grand User Experience – Safety & Maintenance

Modern manufacturing is as much about the operator as it is about the product.

Safety Interlocks: The Grand presses feature fully enclosed pressing chambers with safety sensors. If a door is opened during operation, the machine halts immediately.

Vacuum Dedusting: The images highlight the integration of "Uphill Tablet Dedusters." As tablets exit the press, they vibrate up a spiral while being vacuumed. This removes loose powder, ensuring the tablets are clean before they hit the packaging line.

Ease of Cleaning: The "Console" and mechanical areas are separated. The pressing zone is accessible and designed with smooth stainless steel surfaces to make line clearance and cleaning validation easy.

Conclusion: Investing in Your Production Line

Choosing a tablet press is a 10-year decision. You aren't just buying a machine; you are buying capacity.

The Grand GZPK-26 Plus and the high-speed ZP series offer the perfect balance of cost and performance. They bring the "Intelligent Machinery" standard—usually reserved for premium European brands—to a more accessible price point. With features like Siemens PLC control, vacuum loading, and robust 160,000/hour throughput, these machines are ready to be the workhorse of your facility.

Ready to scale your production?

Don't let outdated machinery bottleneck your growth. Contact Grand Machinery today to configure a ZP or GZPK press that fits your specific tablet size and output goals.