The Expert’s Guide to Shrink Wrap Machines

Top 10 Metal Detectors Suppliers in China

Capsule Filling Machine Export Trends 2026 | Global Capsule Machine

Introduction: The Shifting Tectonics of Solid Dosage Manufacturing

As we look toward the industrial landscape of 2026, the global pharmaceutical industry is undergoing a structural metamorphosis. We are moving away from the era of "one-size-fits-all" blockbuster drug manufacturing and entering a phase defined by precision, agility, and diversification. While the headlines often focus on biologics and gene therapies, the backbone of the industry remains solid dosage forms. Among these, the hard capsule stands out as the most versatile vessel for modern medicine.

However, the machinery required to fill these capsules is evolving. For years, the industry obsession was pure speed—millions of capsules per hour. But as we approach 2026, the priorities are shifting. With the rise of high-potency active pharmaceutical ingredients (HPAPIs), the explosion of the nutraceutical market, and the stringent demands of European GMP standards, the market is swinging back toward flexibility and precision.

This is where the semi-automatic capsule filling machine—and specifically, the liquid-fill capability—is experiencing a renaissance. For equipment manufacturers and exporters, understanding this shift is not just about sales; it is about survival.

In this analysis, I will dissect the market trends leading up to 2026, explain why Grandpackmachine (Grand) has become a preferred partner for European and global pharmaceutical companies, and explore the engineering philosophy that drives high client repurchase rates.

Part 1: The Global Capsule Machine Market Outlook (2024–2026)

The market for capsule filling machinery is projected to grow steadily, but the type of growth is changing. We are seeing a divergence between mega-volume generic production and high-mix, low-to-medium volume specialty production.

1.1 The Drivers of Structural Change

Why is the market behaving this way? Three core factors are reshaping the demand curve:

The "Patent Cliff" and the Generic Boom: As major patents expire, generic manufacturing is surging in Asia, Eastern Europe, and Latin America. These manufacturers do not always need fully automated, million-dollar lines. They need reliable workhorses that can handle multiple formulations with minimal downtime.

The Nutraceutical Explosion: The dietary supplement market is no longer just about herbal powders. It has evolved into complex formulations involving oils, beadlets, and liquid-filled hard capsules. This sector demands machinery that is versatile enough to handle sticky herbal extracts one day and fish oil the next.

Regulatory Scrutiny (The GMP Factor): Regulatory bodies, particularly the EMA (European Medicines Agency) and FDA, are increasing scrutiny on cross-contamination. This favors machines that are easy to strip down and clean. Semi-automatic machines, with their open architecture and removable parts, often offer an easier validation path for cleaning than complex, enclosed fully automatic turrets.

1.2 Regional Export Dynamics: Where is the Machinery Going?

The European Stronghold (The Quality Filter) Europe remains the most critical benchmark for quality. Interestingly, we are observing a distinct trend: European buyers—particularly in Germany, Italy, and Poland—are increasingly sourcing high-end semi-automatic machines from specialized Chinese manufacturers like Grand.

Why? European Contract Manufacturing Organizations (CMOs) often handle smaller batches (50,000 to 200,000 capsules). A fully automatic machine takes too long to set up for these run sizes.

The Trend: European clients are "repurchasing." They buy one unit for a pilot plant, validate it, and then buy three more for production. They value stability over speed.

Asia-Pacific: The Production Engine China and India continue to dominate volume. However, the legacy fleet of equipment in these regions is aging. By 2026, we expect a massive wave of "replacement cycle" purchasing. Factories are looking to replace 15-year-old mechanical fillers with modern, PLC-controlled semi-automatic units that offer better data integrity.

North & Latin America: The Innovation Hubs In the US and Canada, the demand is driven by R&D labs and compounding pharmacies. They need machines that mimic production-scale filling but fit on a benchtop or in a small cleanroom. In Latin America (Brazil, Mexico), the focus is on cost-efficiency. They want European-style reliability without the European price tag.

Part 2: The Engineering Logic: Why Semi-Automatic Reigns Supreme

In an age of Artificial Intelligence and robotics, arguing for "semi-automatic" technology might seem counter-intuitive. However, from an engineering and operational efficiency standpoint, semi-automatic machines remain unbeatable for a significant portion of the market.

2.1 The "OEE" Advantage

Overall Equipment Effectiveness (OEE) is the gold standard for manufacturing metrics.

Availability: Semi-automatic machines have fewer moving parts than rotary presses. Fewer sensors to fail, fewer servos to calibrate. This translates to higher uptime.

Performance: While slower in absolute output, they suffer less from "micro-stops" (jammed capsules) because an operator is present to correct minor issues instantly.

Quality: Modern semi-auto machines use independent augers and variable frequency drives (VFDs) to control powder weight with incredible precision.

2.2 The Liquid Capsule Filling Revolution

By far the most exciting trend toward 2026 is the adoption of liquid-filled hard capsules (LFHC). Historically, if you wanted a liquid oral dosage, you used a Softgel. But Softgels are expensive to develop, require massive minimum order quantities (MOQs), and have stability issues with certain ingredients.

Hard capsules filled with liquid are the solution. However, filling a liquid into a two-piece capsule is hydraulically complex.

Viscosity Challenges: The machine must handle everything from low-viscosity essential oils to thick, paste-like suspensions.

The Sealing Imperative: Once filled, the capsule must be banded or sealed immediately to prevent leakage.

Grand’s Approach: We are seeing a surge in demand for machines like the Grand CGN208-D series modified for liquids. These utilize high-precision peristaltic or ceramic pumps. The advantage of a semi-automatic platform here is visual inspection—the operator can instantly see if a capsule is leaking or if the fill level is incorrect, preventing an entire batch from being ruined.

2.3 Hybrid Technologies (Liquid + Powder)

The frontier of drug delivery is "combination therapy." Imagine a capsule containing a liquid solubilized drug for immediate release, and a pellet or powder mini-tablet for sustained release. Achieving this on a high-speed rotary press is an engineering nightmare. On a semi-automatic Grand machine, it is a matter of sequencing. You fill the liquid, move the tray to the powder station, and top it off. This flexibility allows R&D teams to prototype formulations that were previously impossible.

Part 3: Addressing Buyer Pain Points (The Real World)

As an expert analyzing this market, I constantly speak with production managers and procurement officers. Their pain points are consistent, and they drive the design philosophy behind successful exporters.

3.1 The "Changeover" Nightmare

In a modern CMO facility, time is money.

The Problem: On a standard fully automatic machine, changing from Size 00 to Size 3 capsules can take 4 to 8 hours of skilled mechanic time. That is a full shift of lost production.

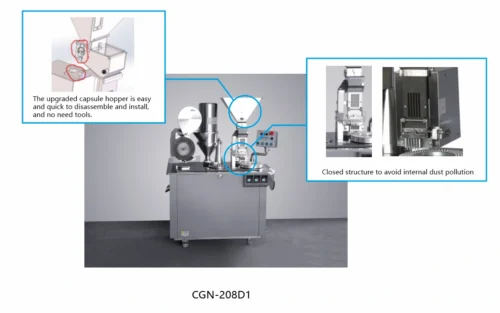

The Need: Buyers demand "Tool-Less" changeovers.

The Solution: Leading designs for 2026 focus on modular moulds. A Grand semi-automatic machine can be changed over in 10 to 15 minutes. This agility allows a factory to run Vitamin C in the morning and an antibiotic in the afternoon with zero cross-contamination risk.

3.2 The "Black Box" Anxiety

Importers, especially those buying from Asia for the first time, fear the "Black Box"—a machine that arrives with no documentation, confusing controls, and zero support.

The Problem: A machine goes down in Germany. The supplier is in China. The manual is in broken English. Production stops.

The 2026 Expectation: Buyers are no longer just buying iron; they are buying the ecosystem. They demand remote HMI (Human Machine Interface) access, video-call support, and exploded-view parts diagrams in perfect English.

3.3 Liquid Leaks and Cross-Contamination

For liquid filling, the fear of leakage is paramount. A leaking oil capsule ruins the packaging and destroys consumer confidence.

The Engineering Fix: This requires a dual approach. First, the machine needs ultra-smooth handling to prevent splashing during the transfer from filling to locking. Second, the locking station must apply vertical pressure perfectly axial to the capsule to snap the locking rings without cracking the dome.

Part 4: The Grandpackmachine Advantage: Why Europe Keeps Coming Back

In this crowded market, Grandpackmachine has carved out a distinct reputation. We are not just selling machines; we are selling process stability. This is evidenced by our remarkably high repurchase rate among European clients—a market known for being the most demanding in the world.

4.1 Engineering Philosophy: "Complexity is the Enemy"

The core design philosophy at Grand is Practical Reliability. We reject unnecessary automation that adds cost without adding value.

The CGN208 Series: This is our flagship semi-automatic platform. It is designed with a "vertical integration" logic. The turntable, the filling auger, and the hydraulic system are enclosed in a stainless steel GMP-compliant housing, but the working area is open and accessible.

Why Europe Loves It: European engineers appreciate robust mechanicals. They look at our drive shafts, our cam boxes, and our welding seams. They see a machine built to last 15 years, not 3.

4.2 The Liquid Filling Mastery

Grand has invested heavily in perfecting the liquid filling module for semi-automatic platforms.

Versatility: Our systems can switch between servo-driven ceramic pumps (for high viscosity) and peristaltic pumps (for zero-contact sterile filling).

Anti-Drip Technology: One of the biggest headaches in liquid filling is the "final drop" that falls on the capsule rim, preventing a seal. Grand machines utilize a "suck-back" mechanism on the nozzles to ensure the rim remains dry and clean for sealing.

4.3 The Export Professionalism Standard

Grand understands that the export process is part of the product quality.

Documentation: We provide full IQ/OQ (Installation Qualification / Operational Qualification) documentation packages in professional English, essential for GMP validation.

Logistics: We know that a machine arriving with a bent hopper is useless. Our vacuum-sealed, shock-proof packaging ensures the machine arrives in Berlin or Brazil in the exact condition it left the factory.

4.4 Solving the Spare Parts Dilemma

One of the reasons clients hesitate to import machinery is the fear of parts obsolescence. Grand employs a "Universal Design" approach. We use standard components (like Siemens or Omron PLCs and Schneider electrics) wherever possible. If a relay fails in France, you can buy a replacement locally. For proprietary mechanical parts, we maintain a 10-year traceability log. If you bought a machine in 2018, we have the exact specs to machine a replacement gear in 2026.

Part 5: Technical Deep Dive – The Grand Semi-Automatic Ecosystem

Let’s look under the hood. What exactly makes the Grand machine a superior choice for the 2026 market?

5.1 Optimized Powder Delivery (The Auger System)

Consistency in weight is the holy grail of capsule filling.

Design: Grand utilizes a variable-speed screw feeder with a specifically designed geometry that pre-compresses the powder slightly before it enters the capsule body.

Benefit: This allows for the handling of "difficult" powders—those that are too fluffy (poor flow) or too sticky. The independent control of the auger speed and the turntable speed allows the operator to "dial in" the perfect weight without changing parts.

5.2 The Pneumatic Capsule Separation System

Traditional machines often damage capsules during the separation phase (pulling the cap from the body).

The Grand Innovation: We utilize a refined vacuum positioning system. The vacuum manifold is designed to apply suction evenly across the dome of the capsule. This results in a separation rate of >99.9%, even with cheaper, lower-quality empty capsules. This tolerance for different capsule qualities saves our clients money on consumables.

5.3 Operator Ergonomics and Safety

In 2026, operator safety is non-negotiable.

Safety Interlocks: The Grand machines are equipped with comprehensive safety grids. If an operator opens the filling guard, the auger stops instantly.

Noise Reduction: We have re-engineered the internal drive mechanics to lower the decibel rating, creating a more comfortable working environment—a key requirement for European labor laws.

Part 6: Future-Proofing Your Production Line

As we look toward 2026, the question for pharmaceutical manufacturers is not "How fast can I produce?" but "How adaptable is my production?"

6.1 The Rise of the "Micro-Factory"

We are moving toward smaller, more distributed manufacturing sites. A giant factory in one country shipping to the world is becoming less viable due to supply chain risks. The future is local manufacturing. Grand’s semi-automatic machines are the perfect engine for this model. They are compact, energy-efficient, and require minimal infrastructure. A startup in Nigeria or a boutique supplement brand in the UK can set up a GMP-compliant line in a 50-square-meter room.

6.2 Sustainability and Energy Efficiency

Sustainability is the buzzword of the decade.

Energy Consumption: Grand machines are engineered to be low-energy consumers. We use high-efficiency motors and optimize the pneumatic systems to reduce compressed air usage (which is often the most expensive utility in a factory).

Waste Reduction: By achieving high filling accuracy (>99%), we reduce the waste of expensive APIs (Active Pharmaceutical Ingredients). In the world of oncology or cannabinoids, every milligram counts.

6.3 The Shift to HPMC (Vegetarian) Capsules

The world is going plant-based. HPMC (Hydroxypropyl Methylcellulose) capsules behave differently than Gelatin capsules—they are slightly more brittle and have different friction coefficients. Grand machines are "HPMC Ready." Our capsule handling plates and separation vacuum levels are calibrated to handle vegetarian capsules gently, preventing cracking and ensuring high yield.

Conclusion

The pharmaceutical machinery market is crowded, but clarity is emerging. The race for pure speed has slowed; the race for reliability, flexibility, and service has begun.

For the pharmaceutical manufacturer in 2026, the ideal production line is one that can pivot instantly between products, handle liquids and powders with equal ease, and operate for years with minimal maintenance.

Grandpackmachine stands at the intersection of these needs.

Our dominance in the semi-automatic sector, particularly our growing market share in Europe, is not an accident. It is the result of listening to the market. We heard the complaints about difficult changeovers, we heard the fears about liquid leakage, and we engineered solutions.

Whether you are a startup venturing into nutraceuticals or a multinational pharma giant looking for a pilot-plant solution, the choice of machinery will define your success. By choosing Grand, you are choosing a partner that values engineering integrity, understands the export landscape, and is committed to your long-term operational success.

Let us build the future of dosage delivery together.