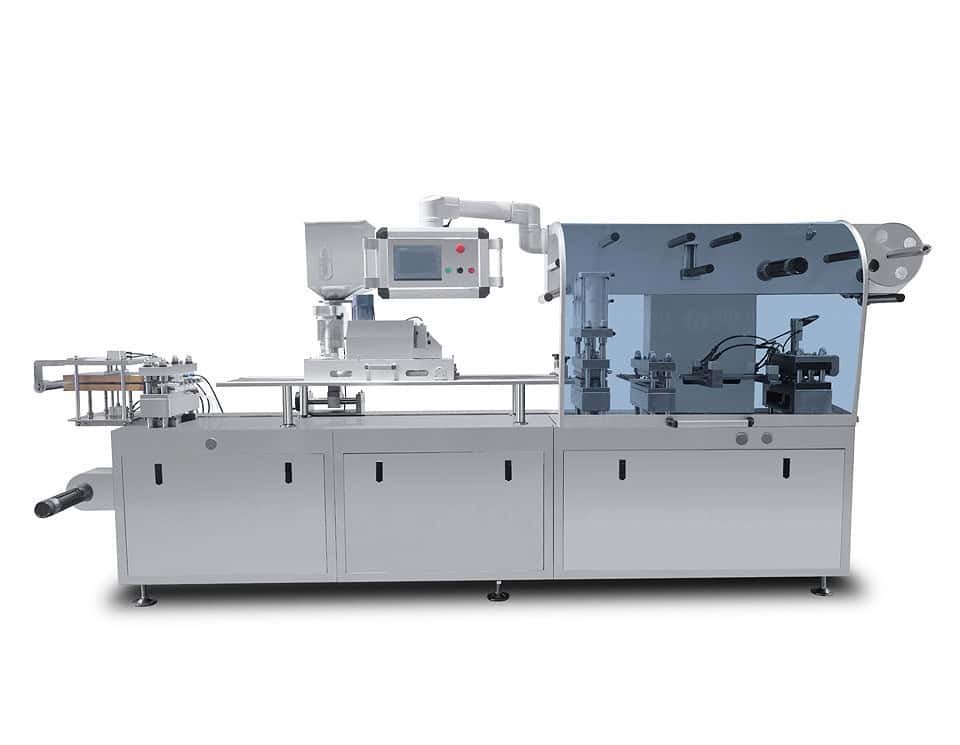

Alu Blister Tablet Packing Machine DPP-270

The Alu blister packaging machine is a flagship product meticulously developed by Grand Group.

Features

High Efficiency: The punching frequency reaches up to 200 times per minute, quadrupling the speed of traditional blister packaging machines.

Innovative Design: Combines the benefits of both flat-type and drum-type blister packaging machines, featuring a specially designed tablet feeder.

Precision and Energy Saving: Delivers high punching frequency with energy efficiency and accurate positioning.

User-Friendly: Easy mold replacement with a finish blister packaging rate, ensuring smooth and efficient operation.

Descriptions:

Omron PLC Control: Equipped with Omron PLC programmable control and a color touch screen, allowing for precise speed adjustment and achieving 100% automated production.

Enhanced Safety: Features automatic position detection, alarm systems, fault diagnostics, and automatic shutdown to enhance operator safety.

Material Protection: Utilizes air vibration feeding and inventory control in the detection hopper, reducing stirring and friction to maintain material integrity.

Easy Customization: The Alu blister packing machine is designed for easy disassembly and supports the production of various blister packs. Molds can be customized to suit specific packaging needs.

Patented Sealing Technology: Developed by Grand Group, the patented technology ensures complete sealing of the Alu foil, maintaining stability and preventing shaking during the packaging process.

User-Friendly Film Roll Device: Features an easy-to-use film roll device with a conveyor for neat and efficient finished product output.

Versatile Packaging: Supports multiple packaging options, including candy, chocolate, milk tablets, and other hard candies.

Convenient Access: The machine is easily disassembled, allowing for convenient transport and access within elevators and workshops.

Specifications

| Condition: | New |

| Warranty: | 3 Year |

| After-sales Service: | Whole Life After-Sale Service |

| Punches Frequency: | 25-60times/Min |

| Travel Range: | 40-120mm (Optional) |

| Air Pressure: | 0.4-0.6 MPa |

| Main Motor Power: | 0.8kw |

| Total Power: | 380V 50Hz 2.25 Kw (Customized Available) |

| PVC Material: | 0.25-0.50*260mm |

| Production Capacity ( Pieces/H): | 2000-5000 |

| Production Capacity: | 20 Sets Per Month |

| PVC Material: | 0.25-0.50*260mm |

| Ptp Alu Foil: | 0.02-0.035*260mm |

| Dialysis Paper: | 50-100g*260mm |

| Mold Cooling: | Running Water or Recycle Water |

| Noise Index: | Less Than 75dba |

| Machine Weight: | 1850kg |

| Wooden Case: | 4460*650*1700 mm |

FAQS

Here are some FAQs

Quadrupling the speed of traditional systems and significantly enhancing production efficiency.

Ensuring accurate positioning and complete sealing for every blister pack.

Allowing it to produce a wide range of blister packs to meet specific requirements.

and automatic shutdown, ensuring a safe operating environment.