Do Gummy Bears Expire? | GrandPack

Why Are Gummies Acidic? The Tangy Truth About Gummy Candy

How to Make Capsules: Step-by-Step Capsule Manufacturing Guide

Introduction

Whether you’re a small-batch herbalist or scaling up to commercial production, knowing how to make capsules correctly is key to safe, uniform, and efficient output. In this guide, GrandPack shows you every stage—from choosing a capsule filler tray to operating a 00 capsule machine—so you can start making capsule pills that meet quality standards.

Understanding Capsule Basics

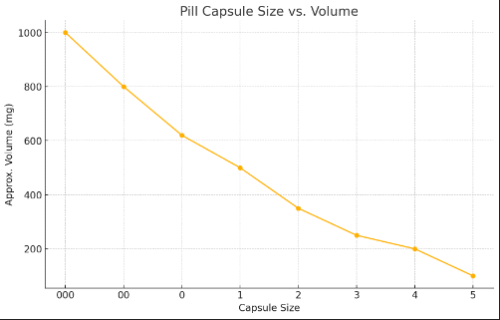

Before diving into equipment, it helps to review the pill capsule size chart and capsule materials. Size “00” is one of the most popular, holding about 400–500 mg of powder (depending on density). Smaller or larger sizes—from “4” up to “000”—are chosen based on dose volume and swallowability.

Preparing Your Capsule Filling Equipment

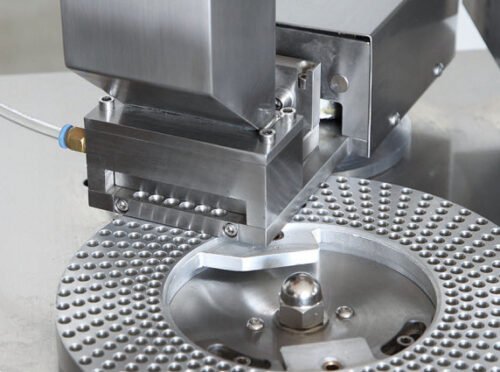

Choosing the Right Capsule Filler Tray

A reliable capsule filler tray is the foundation of any batch. Look for trays with:

Stainless-steel construction (easy to sanitize)

Precision holes sized to your selected capsule dimension

Quick-release hinges for fast cleaning

Use the DIY capsule filler approach for hobby batches: 24-well plastic trays plus a tamper plate can work for < 100 capsules per run. For larger volumes, upgrade to a semi-automatic machine.

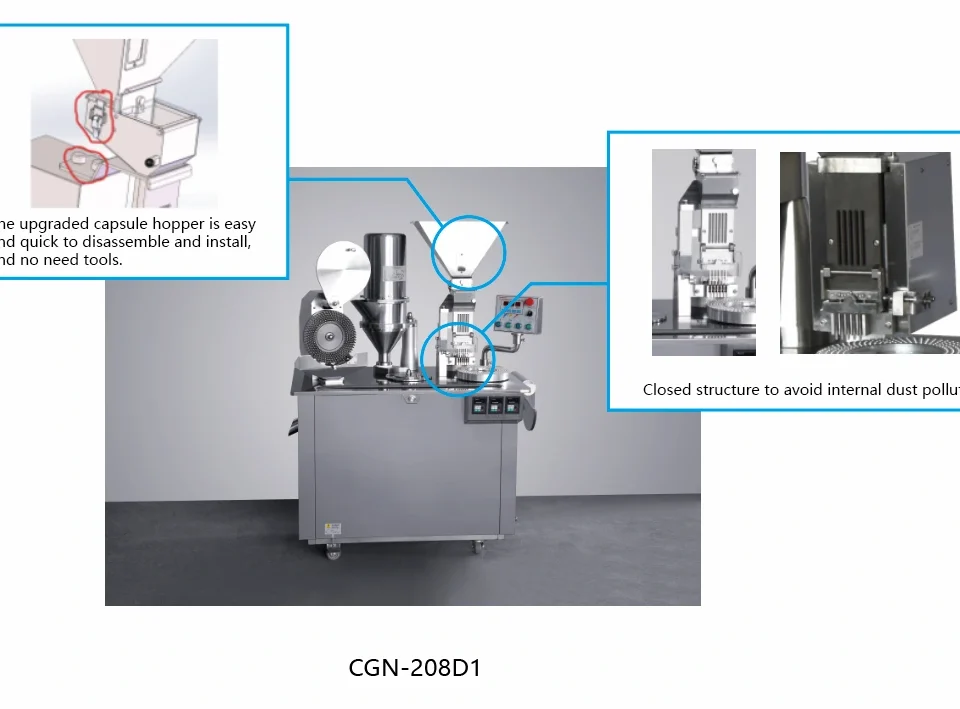

Setting Up a 00 Capsule Machine

For higher throughput, a 00 capsule machine offers speed and consistency. GrandPack’s Model GP-00S features:

Automatic capsule separation

Powder dosing station

Air blow-off for debris removal

Re-cap assembly

To install:

Level the machine on a stable surface.

Load size-00 empty capsules into the hopper.

Calibrate doser depth for your powder blend.

Run a small test batch, then adjust tamping pressure.

Learn more about our 00 capsule machine for industrial output.

Step-by-Step Guide on How to Fill Capsules

Separate capsule bodies and caps. Lock bodies into the tray.

Spread powder across the tray holes. Use a scraper to level all holes evenly.

Tamp the powder gently for a uniform fill. Repeat spreading and tamping if needed.

Place caps over filled bodies and press together.

Eject finished capsules onto a clean tray.

!Download Grand free pill capsule size chart to select the perfect fit.

Tips for Efficient Making Capsule Pills

Use the right lubricant. A tiny amount of magnesium stearate can reduce sticking.

Control humidity. Aim for 40–50% RH in your filling room.

Weigh sample capsules. Check for consistency: ±5 mg variance is ideal.

Clean frequently. Powder buildup slows down runs and risks cross-contamination.

Quality Control and Manufacturing Capsules Best Practices

When manufacturing capsules at scale, compliance matters.

Visual inspection: Reject misshapen or under-filled capsules.

Disintegration and dissolution testing: Ensure capsules release contents properly.

Batch records: Document every parameter—tray type, machine settings, powder lot.

Implement a routine cleaning schedule for your 00 capsule machine and related equipment to meet GMP requirements.

1 Comment

[…] simple to operate and easy to clean, making them perfect for beginners. If you follow the recommended steps—separating capsule parts, spreading powder, tamping, and sealing—you achieve consistent […]