Tube Filling Machine: 5 Things You Must Know

6 Essential Requirements for Pharmaceutical Packaging: A Comprehensive Guide

Grandpack: Revolutionizing Pharmaceutical Packaging Solutions

In the fast-evolving pharmaceutical industry, packaging plays a crucial role in ensuring product safety, regulatory compliance, and operational efficiency. Grandpack, a premier provider of pharmaceutical packaging solutions, has been at the forefront of innovation for over a decade. With a commitment to quality and cutting-edge technology, Grandpack continues to set new standards in efficiency, automation, and precision.

The Role of Advanced Technology in Pharmaceutical Packaging

The integration of computational technology and automation has significantly enhanced the pharmaceutical packaging sector. Grandpack has embraced Industry 4.0 and IoT-driven solutions to streamline operations, reduce downtime, and ensure optimal performance. By leveraging machine learning and predictive analytics, the company has reduced equipment downtime by 25%, resulting in improved production efficiency and minimized operational risks.

Key Features of Grandpack’s Pharmaceutical Packaging Solutions

Grandpack specializes in providing state-of-the-art pharmaceutical packaging solutions, tailored to meet the evolving needs of modern production environments. The company's diverse product portfolio includes:

1. Tube Filling Machines

Grandpack’s tube filling machines are designed for industries such as pharmaceuticals, cosmetics, and food processing. Offering both semi-automatic and fully automatic models, these machines ensure high-speed, precise filling and sealing, effectively reducing labor costs and production inefficiencies.

2. Vial Filling and Capping Systems

For sterile pharmaceutical packaging, Grandpack provides advanced vial filling and capping solutions that guarantee hygienic, high-speed liquid filling. These machines integrate capping and labeling functions, streamlining the packaging process while maintaining rigorous quality control standards.

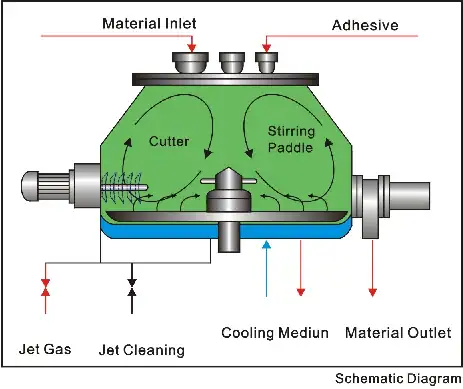

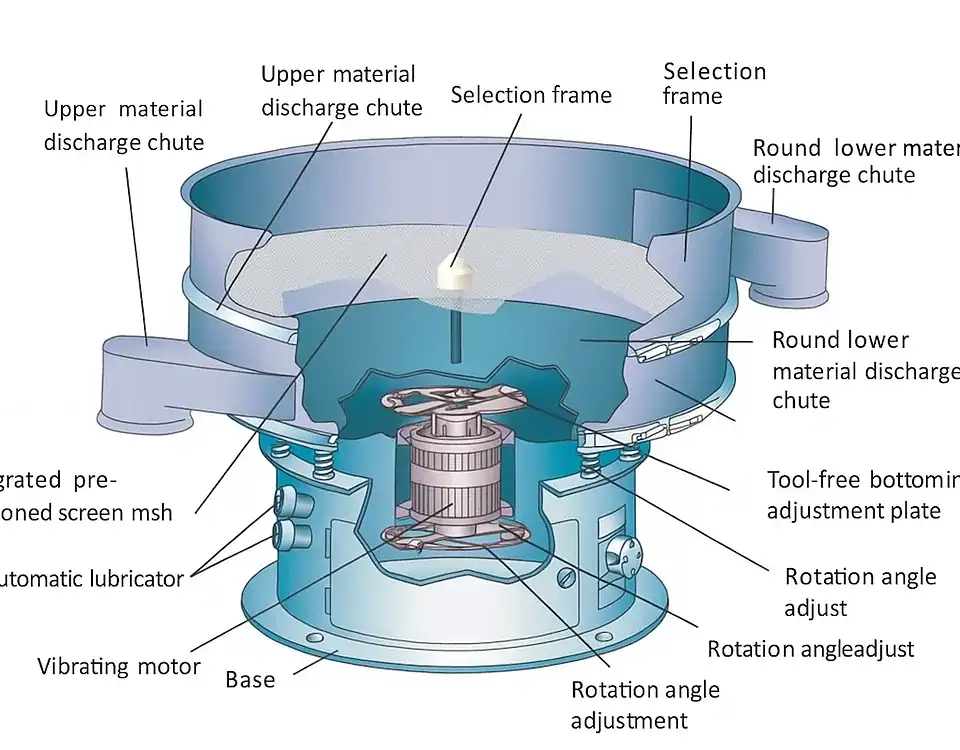

3. Solid Dosage Packaging Lines

Designed for tablet and capsule production, Grandpack’s solid dosage packaging systems offer fully automated solutions that minimize human error and enhance production efficiency. These systems strictly comply with Good Manufacturing Practice (GMP) regulations, ensuring consistency and regulatory compliance.

Why Choose Grandpack for Pharmaceutical Packaging Solutions?

As a leading supplier of pharmaceutical packaging solutions, Grandpack stands out with its unwavering commitment to innovation, quality, and global reach. Key advantages of partnering with Grandpack include:

- Over 10 years of expertise in pharmaceutical packaging solutions.

- GMP and ISO 9001:2015 certifications, ensuring top-tier quality standards.

- Customized packaging solutions tailored to meet specific production needs.

- A global presence with more than 3,000 clients across 100+ countries.

- Unmatched precision and efficiency, delivering high-speed, accurate performance.

Shaping the Future of Pharmaceutical Packaging

With the pharmaceutical industry continually evolving, Grandpack remains dedicated to advancing packaging technology through AI-driven automation, smart manufacturing, and sustainable solutions. By integrating cutting-edge computational technology, Grandpack ensures that its machines remain at the forefront of modern pharmaceutical production.

About Grandpack

Grandpack, headquartered in Guangzhou, China, is a renowned manufacturer of pharmaceutical packaging solutions. The company is dedicated to enhancing pharmaceutical production through automation, efficiency, and technological advancements.

For more information on how Grandpack is transforming pharmaceutical packaging, visit Grandpack news.