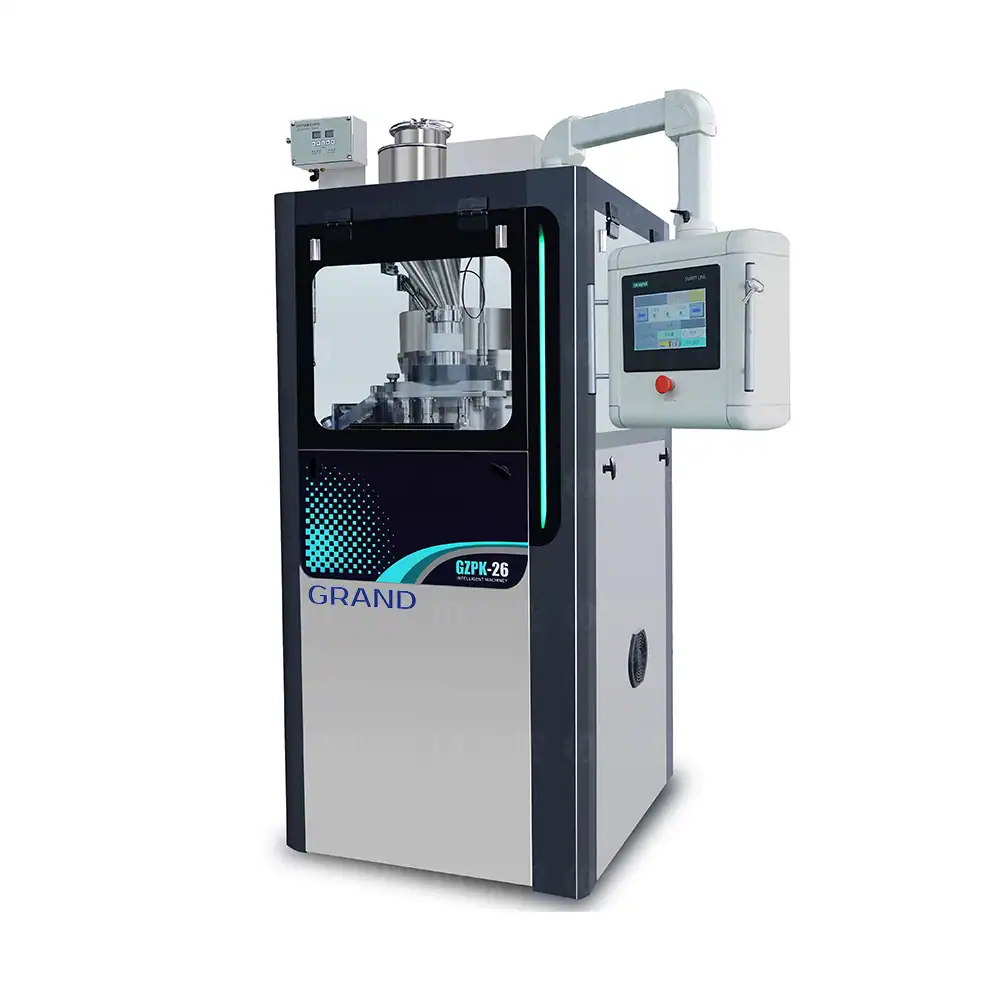

Grand GZPK‑26 Plus Rotary Tablet Press Machine

In today’s demanding pharmaceutical and nutraceutical industries, efficient production hinges on precision and reliability. The Grand GZPK‑26 Plus rotary tablet press combines state‑of‑the‑art automation with rugged construction to deliver consistent, high‑throughput tablet forming. Whether you’re scaling up clinical trials or running 24/7 manufacturing, this automatic tablet press adapts seamlessly to your pill making equipment needs.

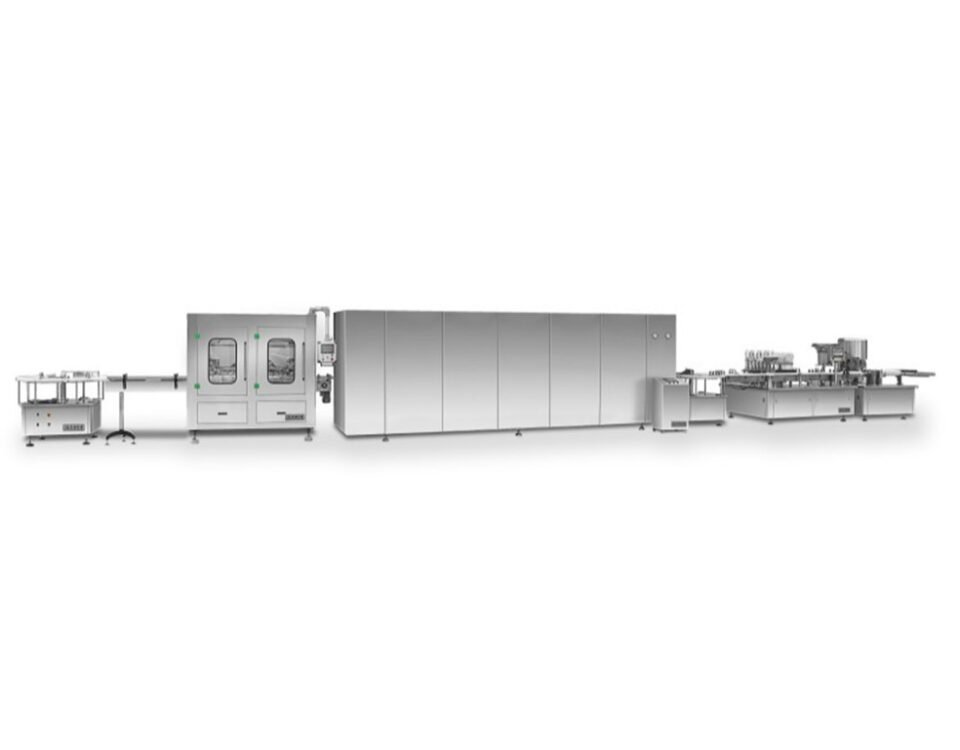

The video shows the operation process of the rotary tablet press. This single machine can also be perfectly connected with the Grand aluminum-plastic blister machine (tablets) and the drug cartoning machine to realize the whole process from tableting production to cartoning.

Applications & Suitable Industries

Pharmaceuticals: Uncoated, coated, chewable, and effervescent tablet production.

Nutraceuticals: Vitamin, mineral, and herbal supplement tablets with precise dosage control.

Chemical & Specialty: Compression of catalysts, detergents, and specialty powders.

Food & Confectionery: Candy tablets, mints, and other edible pellets.

Specifications

| Parameter | Specification |

|---|---|

| Model | GZPK‑26 Plus |

| Number of Stations | 26 |

| Capacity (tablets/hour) | Min. 30,000 – Max. 160,000 |

| Rotation Speed (rpm) | Min. 11 – Max. 102 |

| Max. Tablet Diameter | Φ25 mm |

| Main Pressure | 100 kN |

| Pre‑pressure | 20 kN |

| Max. Filling Depth | 20 mm |

| Die Diameter | 38.1 mm |

| Punch Length | 133.6 mm |

| Main Motor Power | 11 kW |

| Dimensions (L × W × H) | 1530 × 1170 × 1950 mm |

| Net Weight | ≈ 2000 kg |

Key Features of the GZPK‑26 Plus Rotary Tablet Press

High‑Speed Production

- Output Range: 30,000–160,000 tablets per hour.

- Speed Control: 11–102 RPM variable turret rotation for optimal dwell time and compression quality.

Precision Compression System

Maximum Compression Force: 100 kN, with 20 kN pre‑pressure to minimize lamination and capping.

Digital Pressure Monitoring: Real‑time feedback at each station ensures tablet weight and hardness consistency.

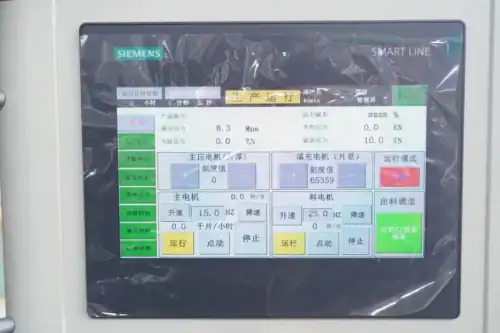

Advanced Automation & Control

Siemens PLC & Touchscreen: User-friendly HMI for recipe storage, process monitoring, and automatic weight adjustment.

Hydraulic Auto‑Control: Maintains user‑defined pressure ranges for stable operations.

Durable, Hygienic Construction

316L Stainless Steel Contact Parts: Sanitary surfaces meet cGMP standards and simplify cleaning.

NSK Bearings & Corrosion‑Resistant Turret: Minimizes maintenance downtime.

Fast Changeover & Maintenance

Quick‑Release Tooling: Standard punch and die sets enable full changeover in under 60 minutes.

High production adaptability

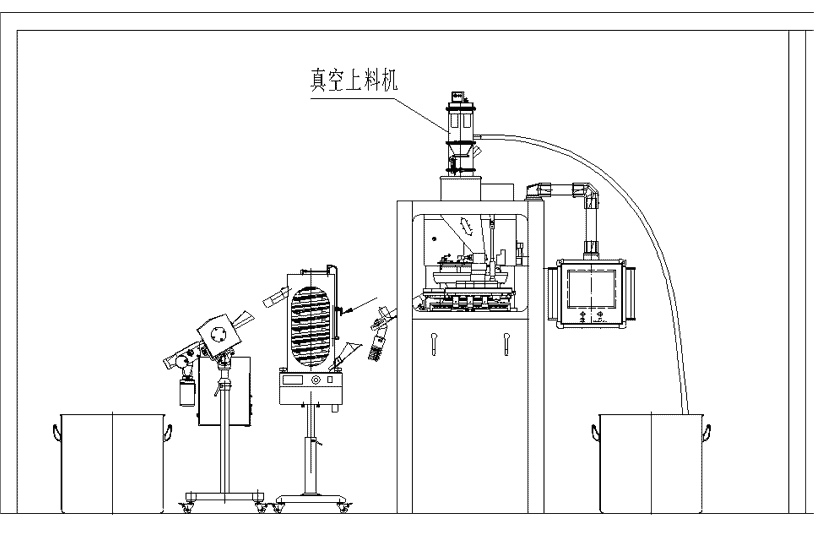

GZPK‑26 Plus Rotary Tablet Press can be perfectly connected to various auxiliary machines. For example, as shown in the right picture, it can be equipped with an automatic loading system (vacuum loading) and a Grand Pharmaceutical Sieving Machine to improve efficiency. It can also be adapted to the following blister packaging machine, etc.

Tablet Press Details

The above pictures show the tablet pressing station, Pneumatic feeding and control screen of the rotary tablet press from left to right.

Why Choose Grand as Your Tablet Press Supplier?

- ✅Proven Track Record

Grand has installed over 1,000 rotary tablet machines worldwide. Our clients report average uptimes above 95%. ✅Comprehensive Support

From on‑site commissioning to operator training and 24/7 technical assistance, Grand ensures your pill machine runs smoothly.✅Customized Solutions

Tailor tooling, process validation, and documentation (IQ/OQ) to meet your unique regulatory requirements.✅Future‑Proof Technology

Modular design allows easy upgrades for SPC data collection, in‑line weight checking, and OEE monitoring.

Service & Technical Suppor

Operator Training

Free, hands‑on instruction for your team on daily operation, die changeovers, recipe setup, and safety protocols—get up to speed fast on the GZPK‑26.

Spare Parts & Consumables

24/7 availability of genuine Grand wear parts (seals, punches, dies, etc.) ensures quick replacements and uninterrupted tablet production.

Scheduled Maintenance

Annual service packages include full cleaning, lubrication, wear‑part swaps, and performance checks to extend equipment life and prevent downtime.

Upgrades & Custom Development

Modular upgrades (extra stations, higher speeds, in‑line weight checks) and custom tooling/software options keep your tablet press ahead of growing production and product needs.

❓Frequently Asked Questions (FAQs)

1.What tablet diameters does the GZPK‑26 support?

Up to 25 mm diameter with fill depths to 20 mm—ideal for most pharmaceutical tablets and dietary supplements.

2.How is tablet weight adjusted automatically?

Enter your target weight on the touchscreen HMI; the system fine‑tunes feed depth and compression force in real time.

3.What changeover time should I expect?

With quick‑release punches and dies, full tooling swap and cleaning take less than 60 minutes.

4.Can it integrate into existing production lines?

Yes. Standard communication protocols support seamless integration with capper, coater, or blister packaging lines.

5.What maintenance does the automatic tablet press require?

Routine lubrication, sensor calibration, and wear‑part inspection. Grand supplies a detailed preventive maintenance schedule.

6.Is GMP‑compliant documentation provided?

Complete IQ/OQ, material certificates, and calibration records are included to support regulatory audits.

7.How do you ensure consistent tablet quality?

Built‑in pressure sensors at each station monitor force; the machine auto‑corrects deviations or halts if tolerances are exceeded.

8.What after‑sales support does Grand offer?

24/7 remote diagnostics, global service network, spare parts kits, and preventive maintenance visits ensure maximum uptime.