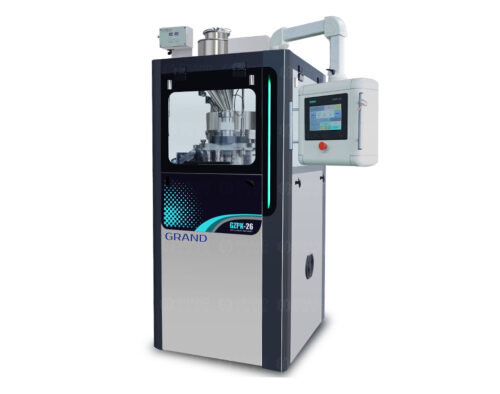

Tablet Press Machine For Sale

Explore our range of tablet press machines for sale, designed for high efficiency and precision in tablet manufacturing. Durable, reliable, and ideal for pharmaceutical and food industries.

Grand Offer Automatic, and Rotary tablet press machines for Pills, Drugs and Medicines.

Tablet Press Machine Features:

Max speed reach up to 350 tablets/minute.

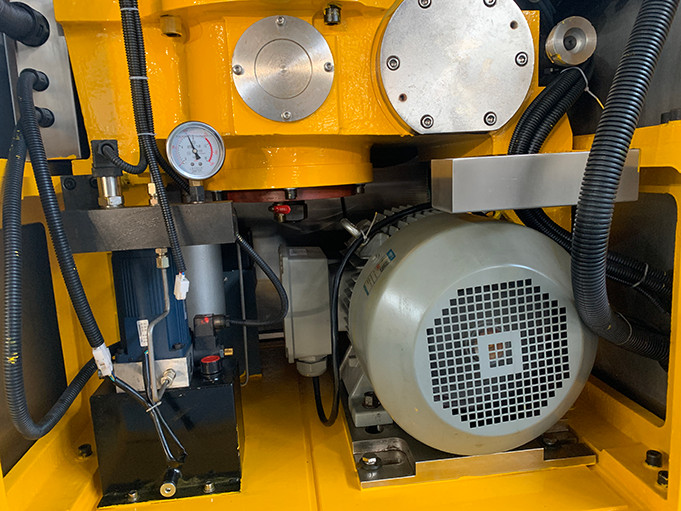

Core Components purchased from: Schneider, Siemens, Mitsubishi, ABB......

Applied Types: manual and fully automatic tablet press models.

Applicable industries: pharmaceutical, candy.

Applications & Suitable Industries

Pharmaceuticals: Uncoated, coated, chewable, and effervescent tablet production.

Nutraceuticals: Vitamin, mineral, and herbal supplement tablets with precise dosage control.

Chemical & Specialty: Compression of catalysts, detergents, and specialty powders.

Food & Confectionery: Candy tablets, mints, and other edible pellets.

Why Choose us Tablet Press Machine ?

Large-Scale Supply

We have a 50,000 square meters factory and available to produce over 50 automatic tablet presses per day.

Timely Delivery

We will evaluate the order delivery time before signing the agreement. We promise to complete the production task 100% within the contract period.

High Quality

All of our tablet press core components are purchased from famous brands in Japan, Germany, Italy, etc., So we always keep high quality for each tablet press machine.

High-Speed Tableting

Our tablet press machine is known for high speed press and it is the fastest type of tablet press machine in the pharmaceutical industry.

Tablet Press Machine For Sale Videos

Featuring a double-layer design and automatic rotation, the tablet press is designed to produce pressed pills and tablets.

It known for their durability and precision, contributing to the overall efficiency and longevity of the machine.

The high-speed tablet press machine, made from stainless steel, features a smooth turntable, a double-press structure for quieter operation

Grand Tablet Press Machine: Your Essential Q&A Guide

Looking to understand the ins and outs of tablet manufacturing? The Grand Tablet Press Machine is a cornerstone of modern production. This guide answers 11 common questions to help you grasp its capabilities, operation, and importance.

1. What Exactly is a Grand Tablet Press Machine?

Tablet Press Machine is a sophisticated piece of mechanical equipment designed to compress powders or granules into tablets of uniform size, shape, and weight. While heavily utilized in the pharmaceutical sector for producing medication, its applications extend to creating cosmetics, cleaning products, and herbal supplements. The primary function of any Grand Tablet Press Machine is to ensure consistent and high-quality tablet output.

2. What are the Main Advantages of Using a Grand Tablet Press Machine?

Investing in a fully Tablet Press Machine offers significant operational benefits. These machines are engineered for high output, capable of producing tens or even hundreds of thousands of tablets per hour, a stark contrast to lower-capacity single punch presses.

Their automated nature means they can efficiently manage powder filling, compression, and the ejection of non-conforming tablets in one seamless process, saving both time and labor. Advanced engineering in a Tablet Press Machine also minimizes common tablet issues like capping and lamination, ensuring a high-quality finish.

3. The Hardness of Tablet: Why It Matters in Pharmaceutical Manufacturing

In pharmaceutical and nutraceutical manufacturing, the hardness of tablet is a critical quality attribute that can literally make or break a product’s success. Tablet hardness refers to the mechanical strength of a tablet – essentially, how much force it takes to fracture or crush it. This hardness of tablet property ensures that pills stay intact through packaging, shipping, and handling, yet still dissolve properly when ingested.

4. What are the Key Parts of a Grand Tablet Press Machine?

A Grand Tablet Press Machine comprises several critical components working in unison:

* Hopper: Feeds raw materials into the machine.

* Feeder System: Ensures a consistent flow of material into the die system.

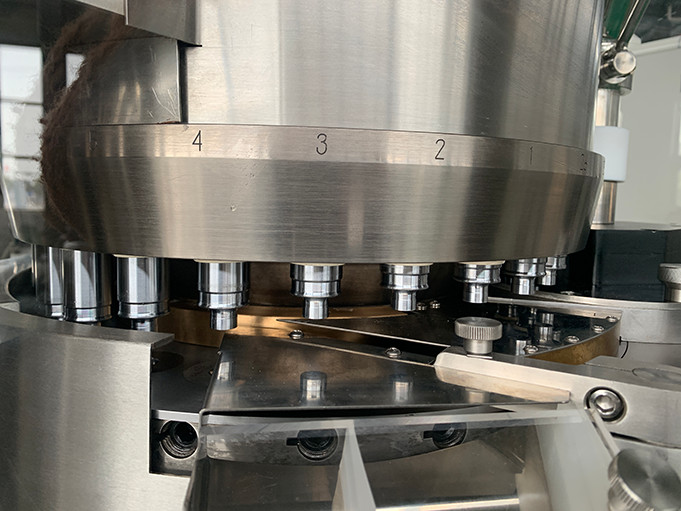

* Punches (Upper and Lower): These move within the dies to compress the powder.

* Die System: Cavities that define the tablet's shape and size.

* Turret: A rotating component that houses the punches and dies.

* Cam Tracks: Guide the punches through the filling, compression, and ejection cycles.

* Compression Rollers (Pre-compression and Main Compression): Apply force to form the tablets.

* Ejection Cam: Facilitates the removal of formed tablets from the dies.

* Take-off Blade & Discharge Chute: Guide tablets to the collection area.

* Control Panel: Allows operators to monitor and adjust machine parameters.

5. How Does a Grand Tablet Press Machine Actually Work?

The operation of a Rotary tablet Machine can be summarized in four stages:

* Filling: Powdered material flows from the hopper into the die cavities as the lower punches are at their lowest point.

* Metering: Excess powder is scraped off the die table, and the lower punch adjusts to achieve the correct fill volume (and thus tablet weight).

* Compression: The upper and lower punches are brought together between large compression rollers, applying immense pressure to form the tablet.

* Ejection: The upper punch retracts, and the lower punch rises to push the finished tablet out of the die cavity, where it's then guided to a collection chute.

6. How Should a Grand Tablet Press Machine Be Cleaned?

Proper cleaning of a Grand Tablet Press Machine is vital for product integrity and machine longevity. The general process involves:

1. Powering down and unplugging the machine.

2. Removing all residual powder from hoppers and surfaces.

3. Systematically disassembling parts like guards, hoppers, feeder systems, punches, and dies. This often requires specific tools and careful attention to the order of removal. 4. Cleaning all disassembled parts (especially product contact parts) and the machine body, often using approved solvents like 95% ethanol and lint-free wipes.

5. Ensuring all die boreholes and punch guides are thoroughly cleaned.

6. Once everything is clean and dry, carefully reassembling the Grand Tablet Press Machine in reverse order.

7. How Do You Specify a Grand Tablet Press Machine for Purchase?

When selecting a Grand Tablet Press Machine, key specifications include:

Compliance with industry standards (e.g., GMP, FDA).

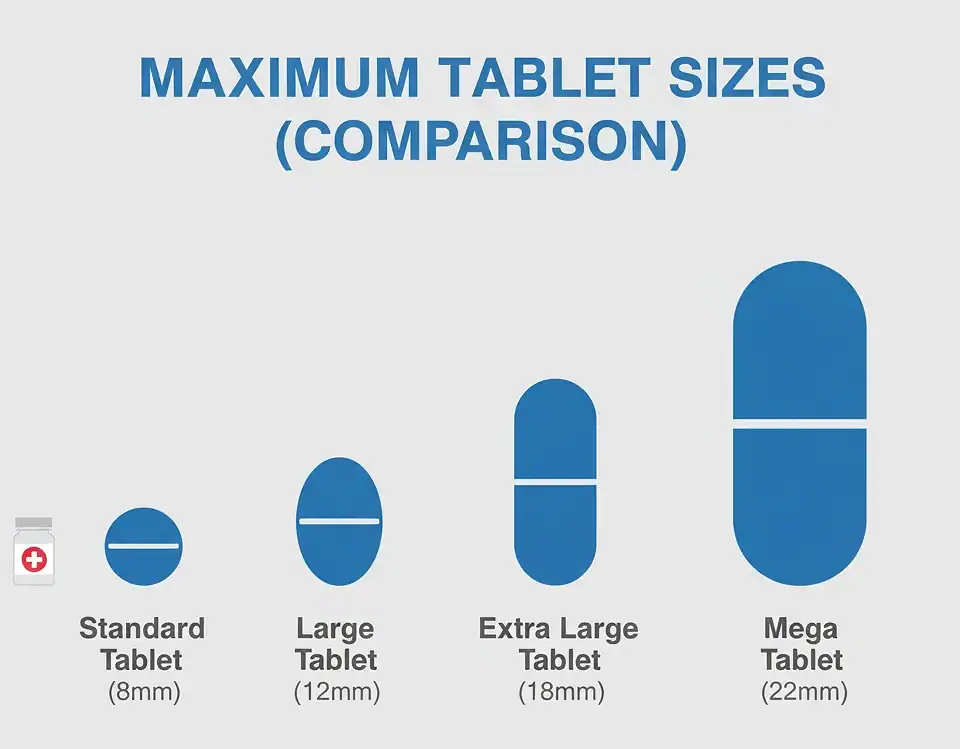

The range of tablet sizes and shapes it can produce.

Maximum production output (tablets per hour).

Construction materials, especially for product contact parts (e.g., 316 Stainless Steel).

Type of control system (e.g., user-friendly automatic controls).

Features like an efficient lubrication system and ease of maintenance.

Availability of attachments like de-dusting units.

8. Why is Tooling Standardization Important for a Grand Tablet Press Machine?

Tooling (punches and dies) standardization (like TSM or EU standards) for a Grand Tablet Press Machine is crucial because it ensures interchangeability of these parts between different machines from various manufacturers that adhere to the same standard. This simplifies sourcing spare parts, reduces inventory needs, allows for more flexible production planning, and can lead to cost savings.

9. Which Industries Commonly Use a Grand Tablet Press Machine?

The primary user of the Grand Tablet Press Machine is the pharmaceutical industry for manufacturing pills and medications. However, its versatility allows it to be used in other sectors, including:

- Nutraceuticals (vitamins, supplements)

- Cosmetics (pressed powders)

- Confectionery (candies)

- Cleaning products (detergent tablets)

- Industrial applications (catalysts, ceramics)

10. What Determines the Production Capacity of a Grand Tablet Press Machine?

Several factors influence the production capacity of a Grand Tablet Press Machine:

Number of stations: More stations on the turret generally mean higher output.

Turret rotation speed: A faster rotating turret produces more tablets per unit of time.

Type of machine: Double-sided rotary presses have a higher output than single-sided ones.

Characteristics of the powder: Flowability and compressibility can limit operational speed.

Tablet size and complexity: Larger or more complex tablets might require slower speeds for quality.

11. What Determines the Efficiency of a Grand Tablet Press Machine?

The efficiency of a Grand Tablet Press Machine isn't just about speed but also about the quality and consistency of the output with minimal downtime or waste. Key determinants include:

Machine Design & Quality: Robust construction and precision engineering lead to fewer breakdowns and consistent tablet quality.

Tooling Quality: Well-made, durable punches and dies are essential for producing good tablets and minimizing defects.

Operator Skill & Training: Knowledgeable operators can optimize settings and quickly troubleshoot minor issues.

Maintenance Practices: Regular preventative maintenance minimizes unexpected downtime.

Powder Quality: Consistent, well-formulated granules lead to smoother operation and better tablets.

Automation Level: Features like automatic weight control and rejection systems improve efficiency by reducing manual intervention and ensuring product conformity.